Image sensor and image read device

An image sensor and imaging optics technology, applied in image communication, electrical components, etc., can solve the problems of deterioration of light receiving accuracy, weak intensity, and inability to prevent ghosting, etc., to achieve the effect of easy positioning adjustment, preventing random reflection, and improving light receiving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0151] Next, the present invention will be specifically described.

[0152] (A) First, the case where the image sensor substrate is miniaturized will be described.

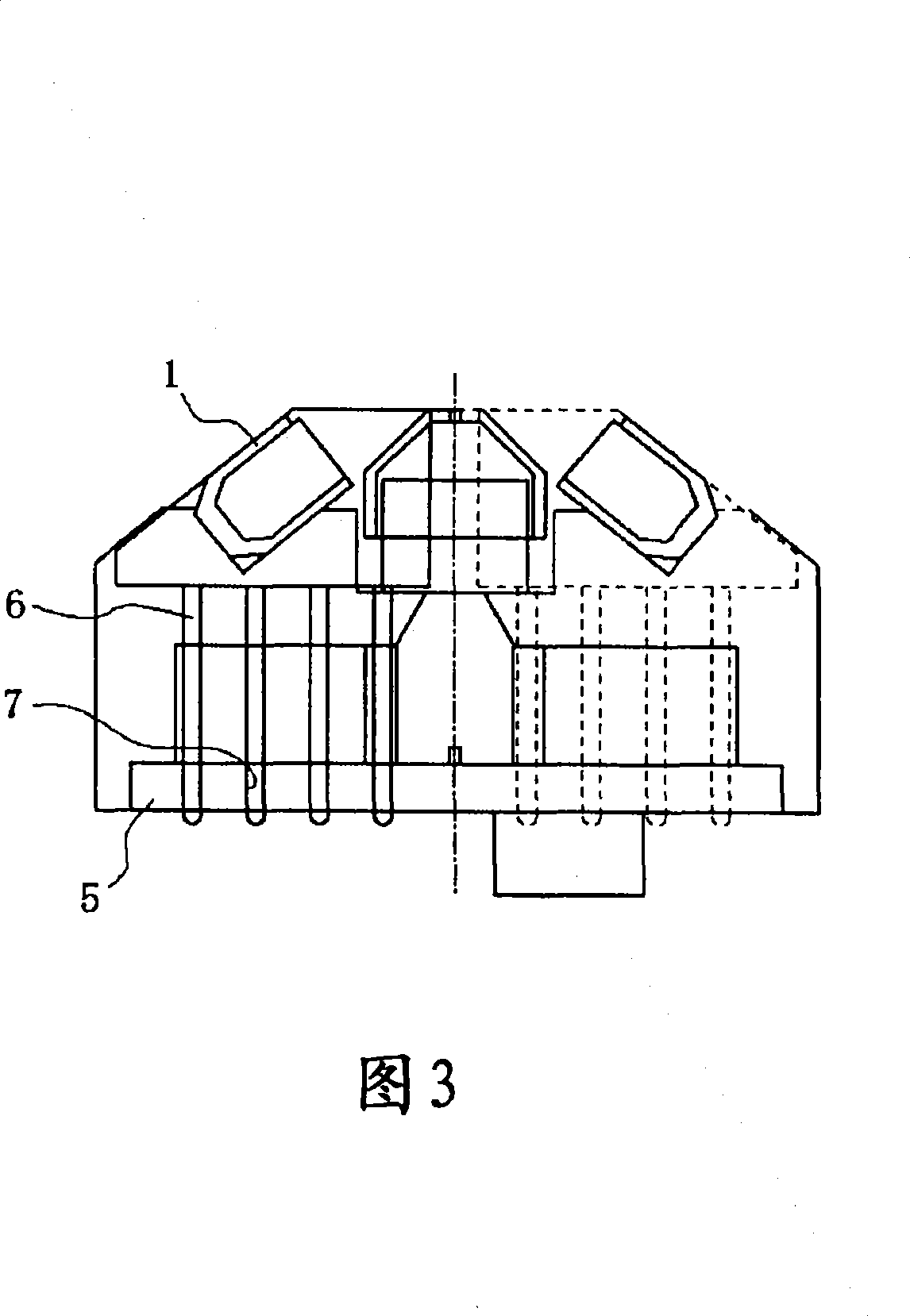

[0153] In addition, at this time, as shown in FIG. 5 , the terminal shape of the lead frame 6 of the rod-shaped light source 1 is changed.

[0154] That is, by bending the terminal of the lead frame 6 of the rod-shaped light source 1 toward the center side (center line side) of the substrate, the position of the through hole 7 in the substrate 5 is moved to the central portion, so that the position of the through hole 7 of the substrate 5 is positioned at the center of the substrate 5. Around the center.

[0155] According to the above configuration, as can be seen from a comparison with FIG. 3 , reduction in substrate width can be achieved.

[0156] The above describes the case where the rod light sources are arranged on both sides of the resin lens plate, but the present invention is not limited thereto, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com