Full-automatic gas dynamic type button-sewing machine

A pneumatic button sewing machine technology, applied in the direction of sewing tools, etc., can solve the problems that two buttons cannot be nailed at the same time, and the efficiency cannot be improved in essence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

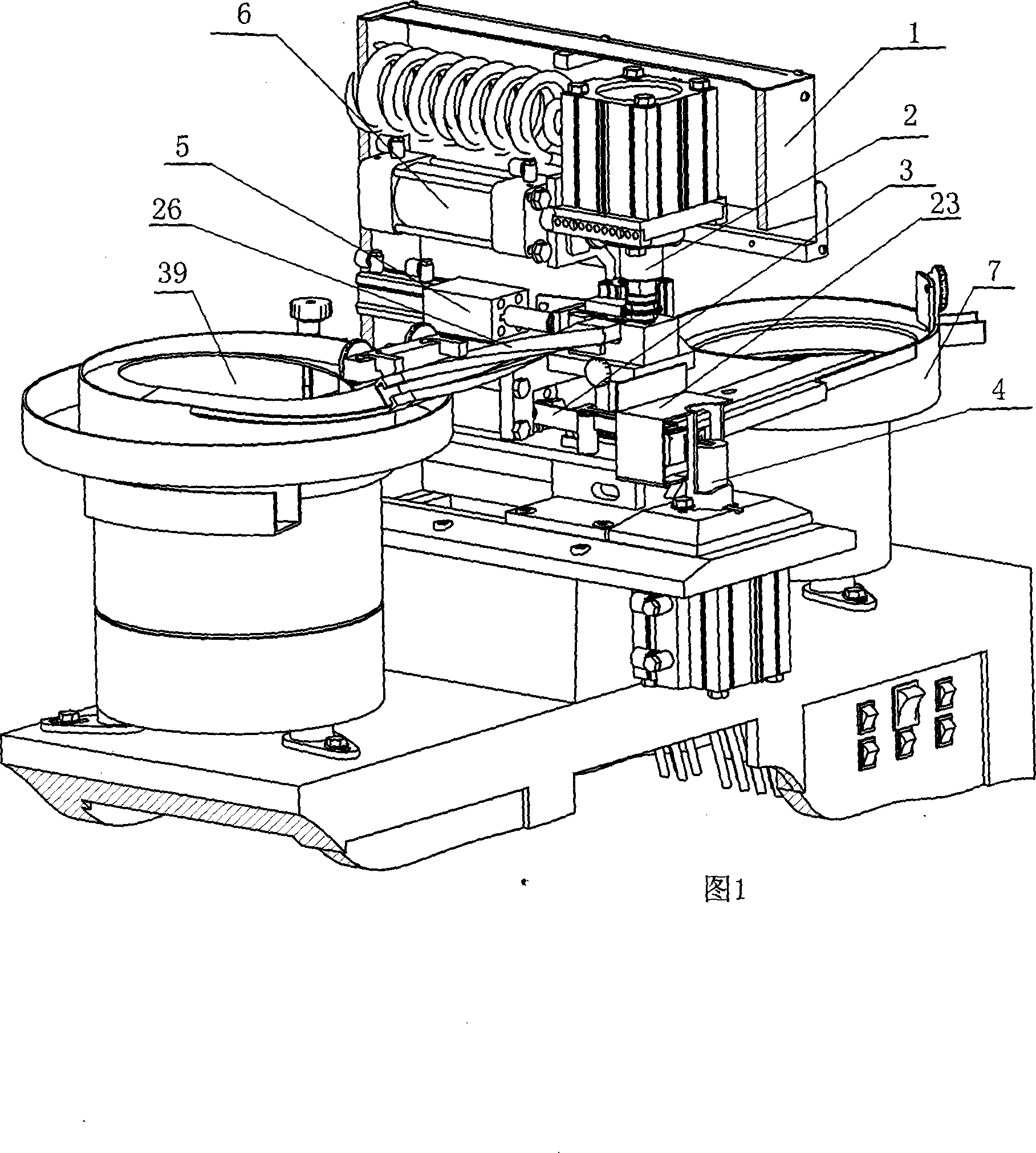

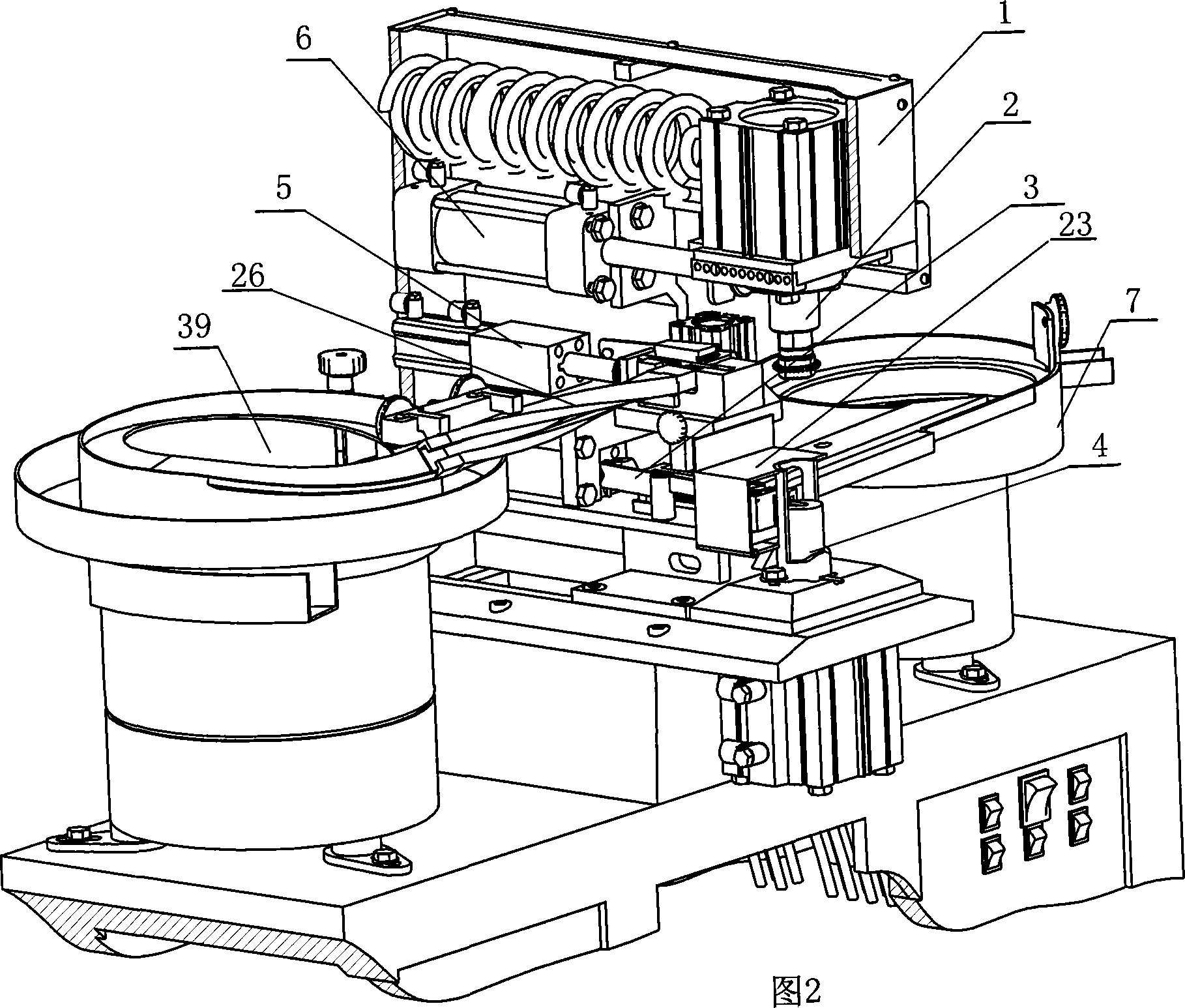

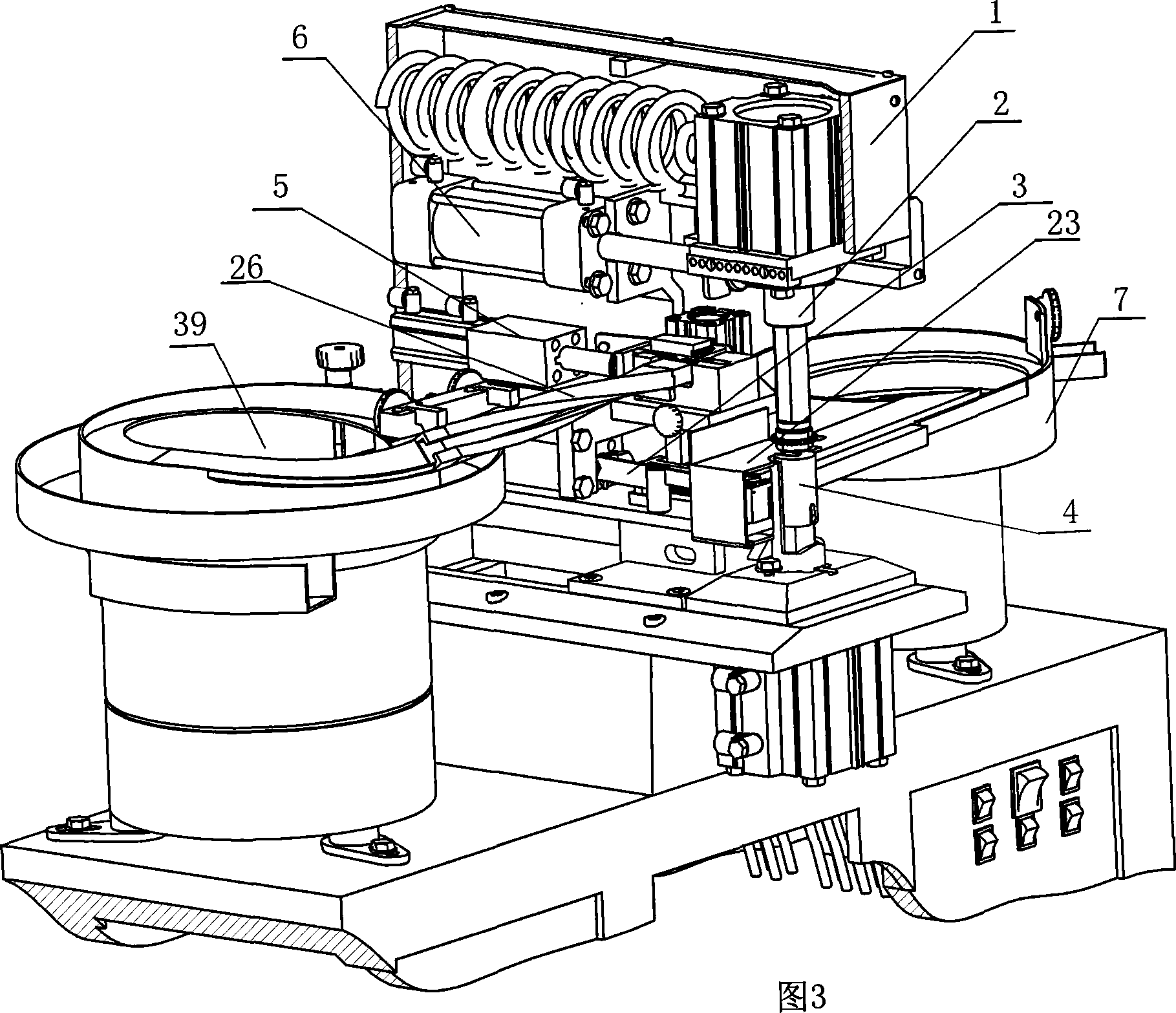

[0014] As shown in Figures 1 to 3, this embodiment includes a head frame 1, an upper punch assembly 2, a lower punch assembly 4, an upper feeding mechanism 5 and a lower feeding mechanism 3, wherein:

[0015] ①The upper punch assembly 2 is slidingly connected to the head frame 1, and the main body of the upper punch assembly 2 is connected to the longitudinal cylinder 6.

[0016] ②As shown in Figure 4, the lower feeding mechanism 3 includes a vibrating lower feeding tray 7, a slideway 9, a lower feeding mold 12, a lower feeding mold channel 10, an automatic return lower stopper device, an automatic return lower push rod 22, The lower feeding cylinder 17, the lower cylinder connecting rod 19, the lower feeding mold channel 10 is arranged on the lower feeding mold 12, one end of the slideway 9 is connected with the outlet of the vibrating lower feeding tray 7, and the other end of the slideway 9 is connected with the side of the lower feeding moldway 10 , there is a vibrating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com