Non-blasting digging method for tunnel and underground project

An underground engineering, non-blasting technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as adverse effects on social stability, panic among residents, endangering safety, etc., achieve significant technical, economic and social benefits, and save engineering investment , The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

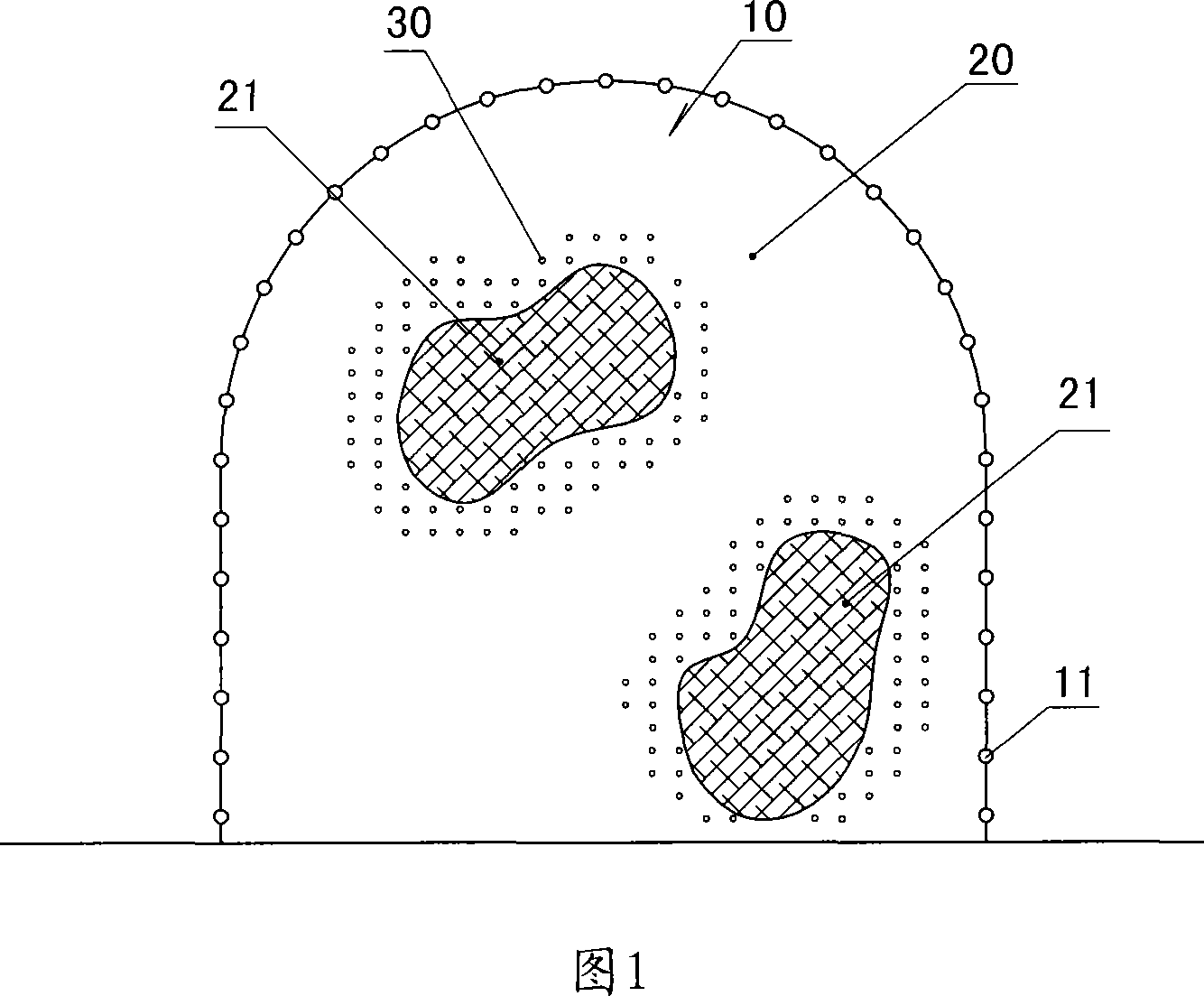

[0024] Referring to Fig. 1, the non-blasting excavation method for tunnels and underground works of the present invention adopts hydraulic breaker as the main method and static crushing as the auxiliary excavation in the soft rock section of the tunnel; adopts static crushing as the main method in the hard rock section. , hydraulic impact hammer for excavation.

[0025] The method comprises the steps of:

[0026] ① Drilling peripheral holes 11 at a certain interval on the outer contour line of the face 10;

[0027] ②Use a hydraulic impact hammer to chisel away the soft rock section on the face 10 and the broken rock mass part 21 in the hard rock mass 20, and create at least one free face in the hard rock mass 20;

[0028] ③Drilling and distributing charge holes 30 on the hard rock mass 20 outside the outline of the air surface, and statically crushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com