Advanced double rows slip casting ductule construction technique

A technology of grouting small conduits and construction technology, which is applied in basic structure engineering, soil protection, protection devices, etc., can solve the problems of poor stratum reinforcement effect, poor self-stabilizing ability, and difficult to control settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: During the construction of Beijing Metro Line 4 Engineering Zoo Station (civil construction), the construction of 1# underground air duct. The air duct is a single-layer underground excavation structure, and the surroundings of the air shaft are relatively close to existing buildings (structures). In the underground excavation construction process, in order to protect the safety of the existing building (structure) structure, the "advanced double-row grouting small conduit construction technology" of the present invention is adopted.

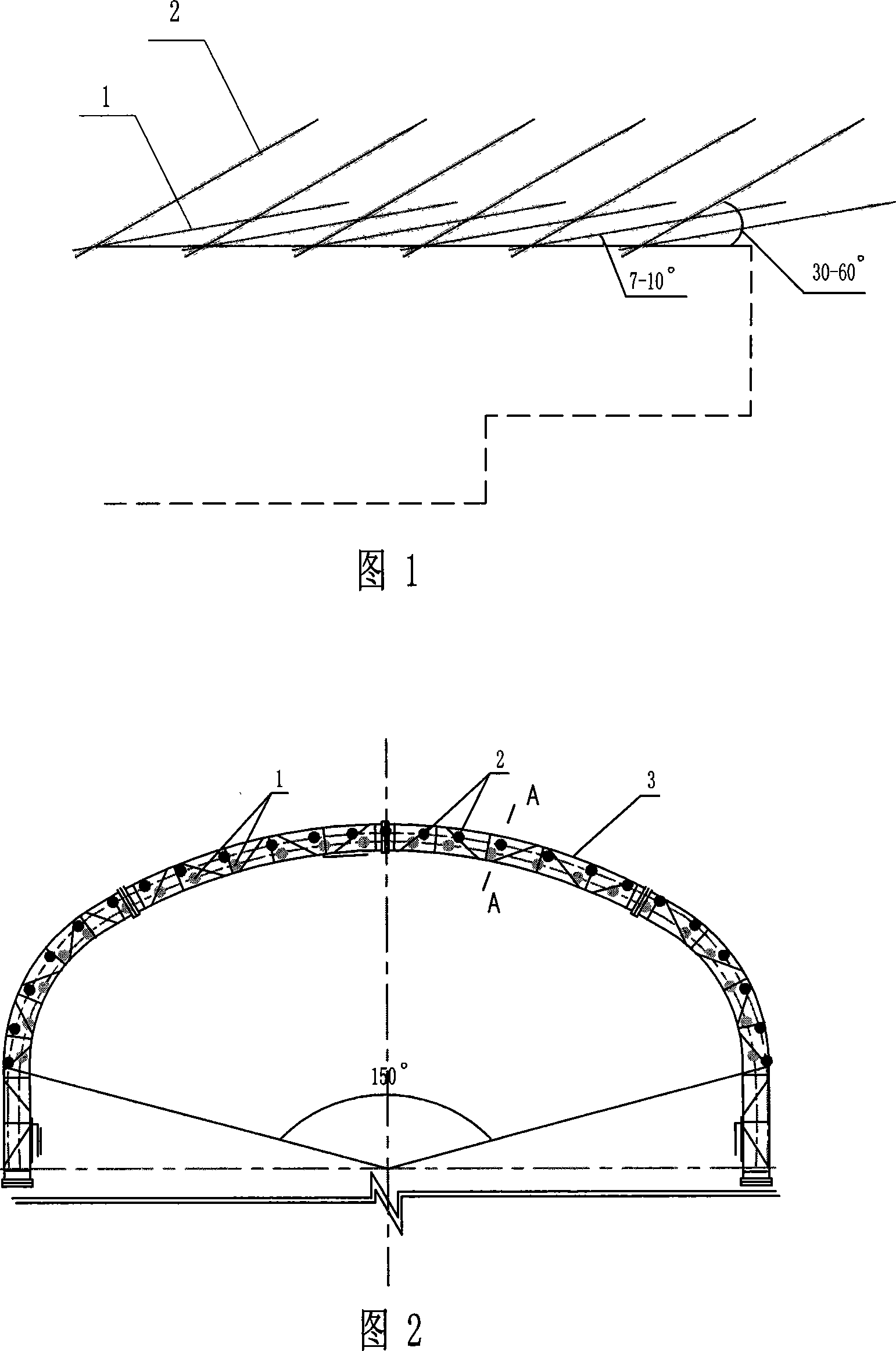

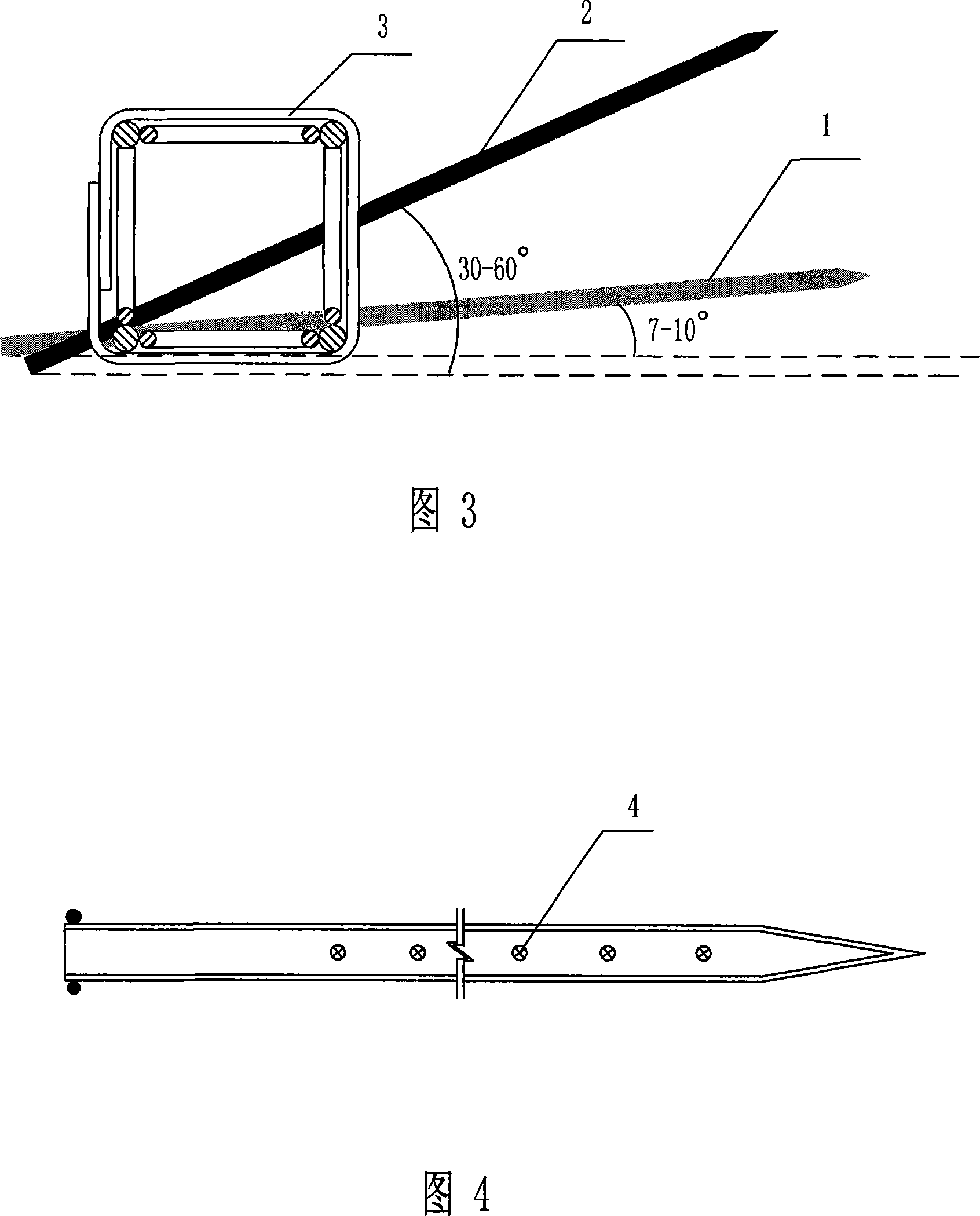

[0027] The advanced double-row grouting small conduit construction technology described in this embodiment is used for underground excavation tunnel construction, and it includes the following steps:

[0028] (1) Excavate the structural shaft, and make a large pipe shed in advance when excavating to the top of the tunnel mouth;

[0029] (2) After excavating the tunnel along the longitudinal direction to meet the standard require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com