Spray device, system and method of using it on spray container pallet part

A technology of spraying device and container, applied in spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of uneven coverage, frequent failure, high maintenance cost, etc., achieve convenient spraying, increase adaptability, meet The effect of rigidity

Active Publication Date: 2010-08-11

CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of spraying with this method is that the coverage between paint and paint is extremely uneven, and the difference in film thickness is too large, resulting in more paint loss

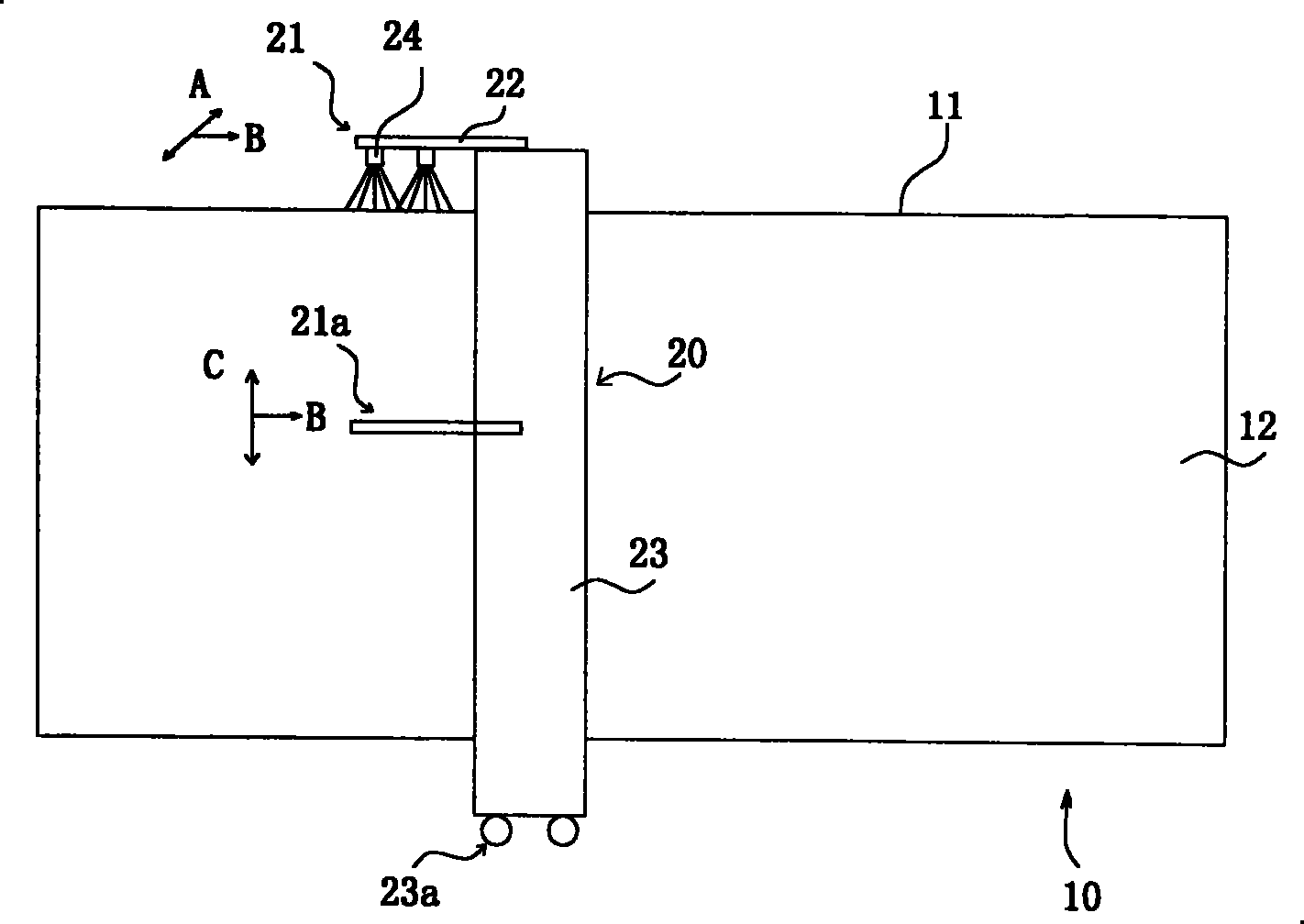

On the other hand, the paint sprayed by the spray gun of the existing automatic paint spraying machine is a flat fan, and its effect is the same as that of the paint brush. , as shown in FIG. 1B is a schematic diagram of one end of the container 10, wherein the corners 14 and 15 of the bottom formed after the bottom plate 13 is connected with two side plates 12, and the top formed after the side plate 12 is connected with the top plate 11 Corner 16 and 17, no matter the inside and outside of these corners all become the dead zone area of spraying operation, because the spraying operation surface of this prior art is only a flat sector

In addition, the automatic paint spraying machine of the above-mentioned prior art is complex in structure, expensive in use, frequent in use, and high in maintenance cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A spray finishing device includes at least one spray gun, a fixing frame used for fixing the spray gun, a swing mechanism fixed with the fixing frame and used for adjusting the angle of the spray gun frame; and a differential device which respectively drives the swing mechanism and the fixing frame through a first chain and a second chain with different speeds. The swing mechanism includes a swing block fixed at the bottom part of the fixing frame, a swing shaft, one end part of which passes through the swing block and is fixed with the swing block; and a swing arm fixed with the other end ofthe swing shaft. In order to optimizing the structure, the spray finishing device also includes a moving block provided with a through hole and fixed with the swing block; among which, the swing shaft passes through the through hole. The first chain and the second chain can be respectively coupled to the bottom parts of the swing block and the moving block, thus allowing the spray finishing device of the invention to automatically adjust the swing angle of the spray gun; thereby being capable of design the swing angle and the swing direction according to detail application.

Description

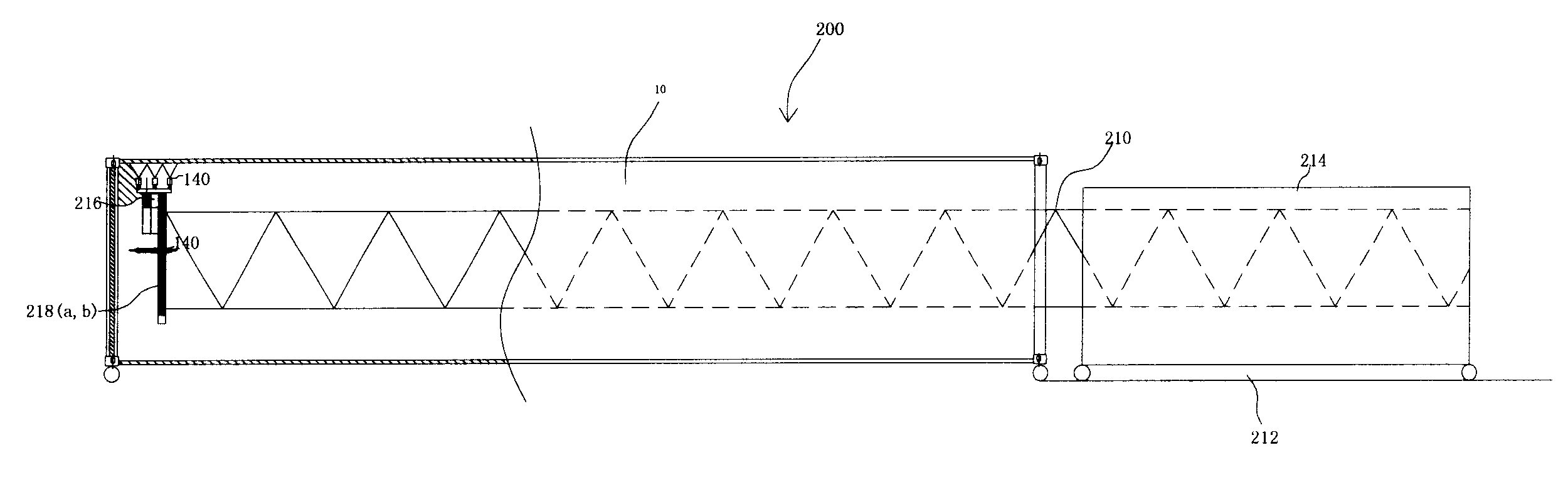

technical field The invention relates to a spraying equipment, in particular to an automatic spraying system used for container spraying and a method for spraying the inside or outside of a panel. Background technique For containers that have been widely used, the external spraying process has already achieved mechanized automatic spraying. Due to various reasons, the sprayers in the box are still in the manual process stage. Although various attempts have been made for realizing the automatic spraying in the case, so far, no ideal scheme can be seen. For the paint spraying outside the box, generally use existing automatic paint spraying machine 200a, as shown in Figure 1A, this automatic painting machine 20 is arranged outside the casing of container 10, and can move along container length direction B (being horizontal direction) . The roof spraying device 21 of the automatic paint spraying machine 20 is fixed on the top of the bracket 23 through a fixing part 22 corres...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05C7/02B05B15/08B05B13/04B05B15/68

Inventor 周远大

Owner CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com