Load bearing type car body

A load-bearing body and right longitudinal beam technology, applied in load-bearing body structure, vehicle parts, transportation and packaging, etc., can solve the problems of large overall bending and torsional rigidity, small body weight, lateral impact force and rear impact force Poor ability and other problems, to improve the ability to withstand collisions and ensure the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

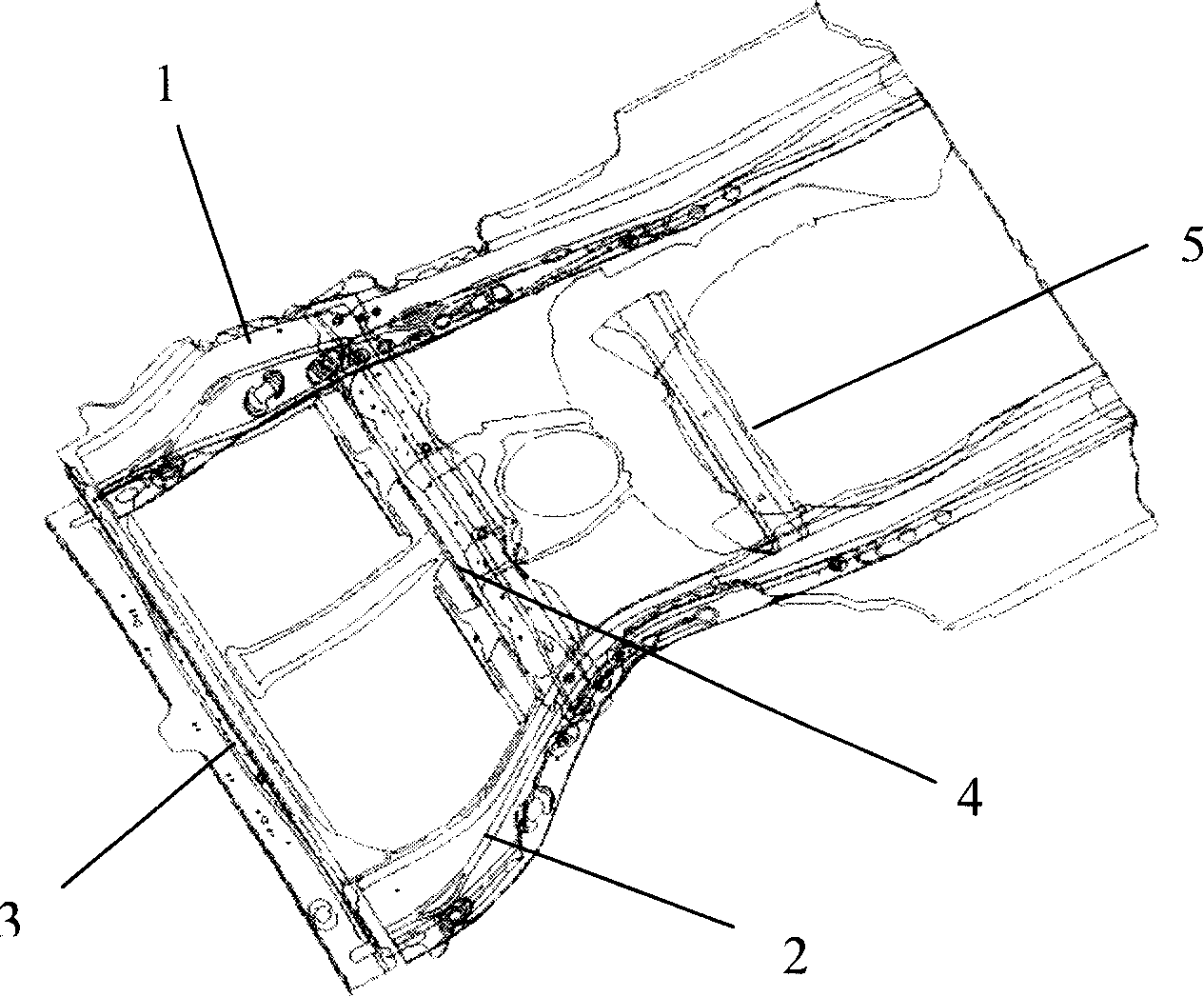

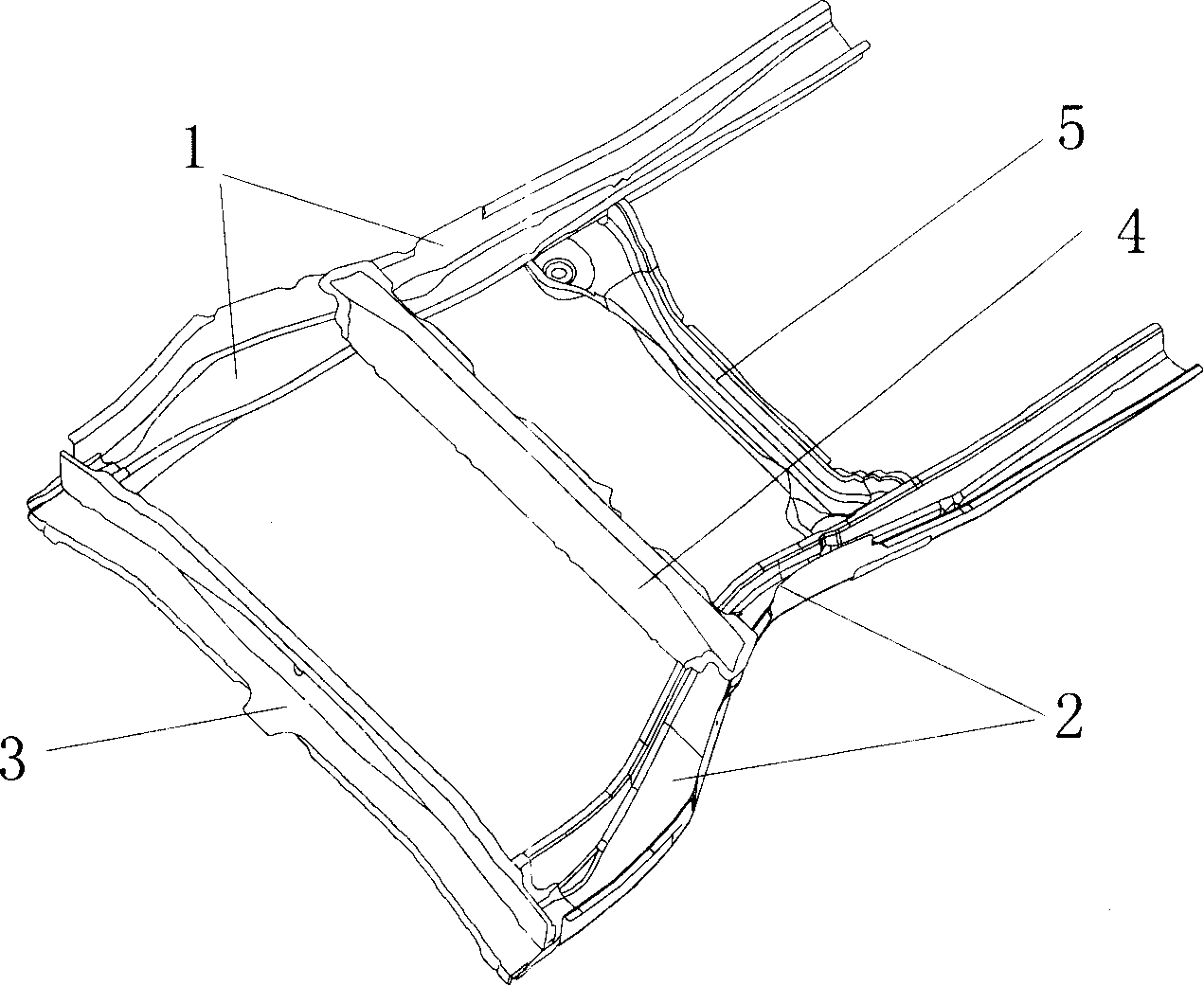

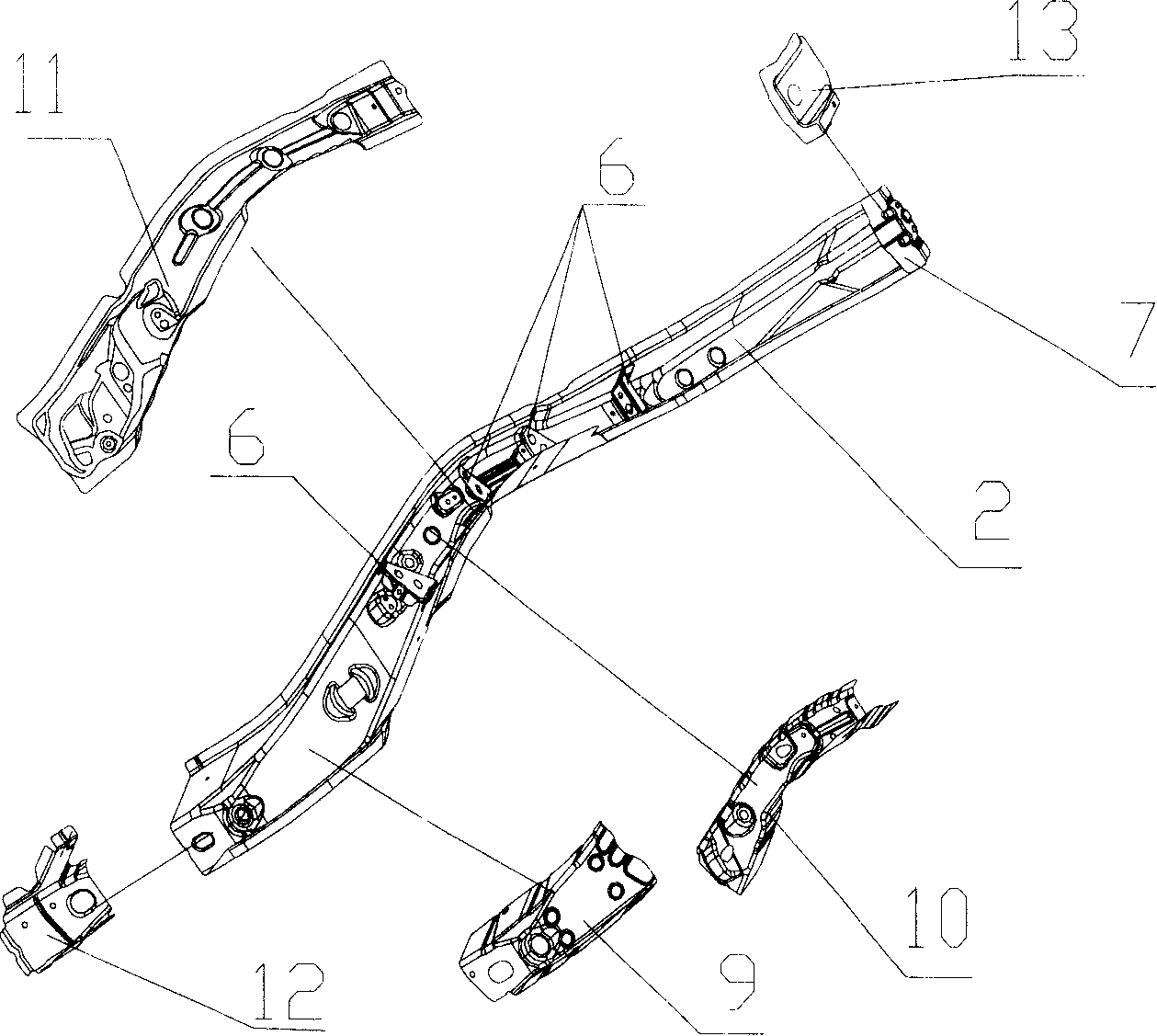

[0035] Such as figure 1 As shown, the load-bearing vehicle body provided by the embodiment of the present invention includes a rear floor of the vehicle body and a reinforcing beam structure fixed on the lower surface of the rear floor. reinforced beam structure such as figure 2 As shown, the left longitudinal beam 1, the right longitudinal beam 2, the front beam 3, the upper beam 4 and the rear beam 5 are included. The left longitudinal beam 1 and the right longitudinal beam 2 extend longitudinally along the left and right frames of the rear floor panel of the vehicle body, and the upper end surfaces of the openings are closely attached to the lower plane of the rear floor panel. The front cross member 3 connects the left longitudinal member 1 and the right longitudinal member 2 at the front ends of the left longitudinal member 1 and the right longitudinal member 2 . The upper beam 4 connects the left longitudinal beam 1 and the right longitudinal beam 2 at the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com