Refrigerator defrosting heater and controlling method thereof

A technology for defrosting heaters and refrigerators, which is applied in defrosting, lighting and heating equipment, and household refrigeration equipment, etc. The effect of extending the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

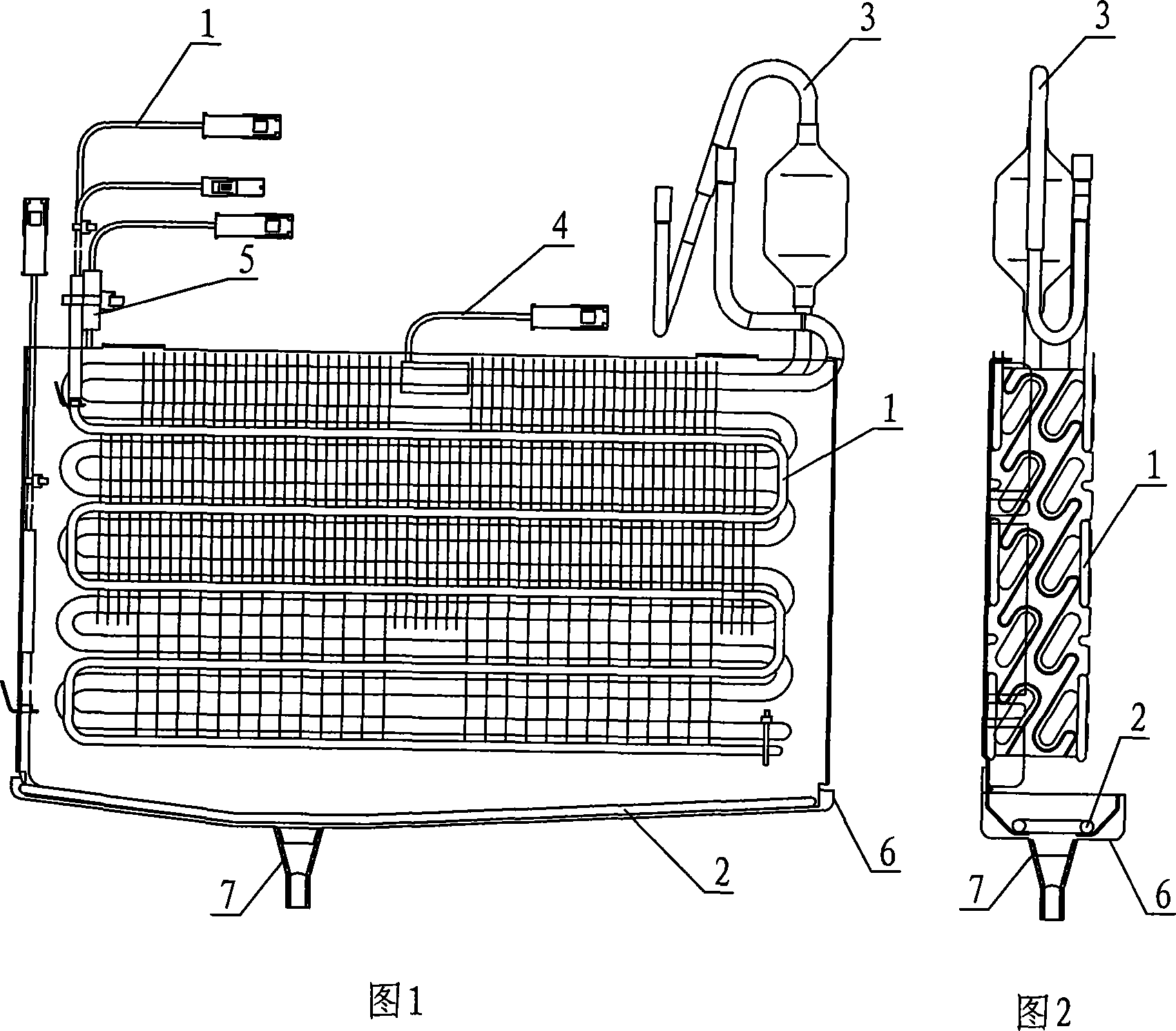

[0017] Referring to Figures 1 and 2, this embodiment sets up independently controllable main heater 1 and auxiliary heater 2 in groups. Main heater 1 is an evaporator defrost heater, and auxiliary heater 2 is a drain pan 6 and a drain pipe. 7's defrost heater.

[0018] The main heater 1 is fixed on the fins of the evaporator 3 in an embedded manner, and the auxiliary heater 2 is fixed on the surface of the water receiving pan 6 and the drain port 7 in a bonding manner.

[0019] Control method of defrost heater:

[0020] When the computer-controlled refrigerator enters the defrosting process, when the defrosting starts, both the main heater 1 and the auxiliary heater 2 are activated and put into defrosting;

[0021] When the surface temperature of the evaporator 3 detected by the temperature sensor 4 rises to the set value, the defrosting of the evaporator 3 is completed, the main heater 1 stops working, and the auxiliary heater 2 continues to work, and the auxiliary heater 2 Heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com