Backlight module

A backlight module and conductive sheet technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of easy breakage of lamp wires and complicated assembly of backlight modules, and achieve the effect of overcoming breakage of lamp wires and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

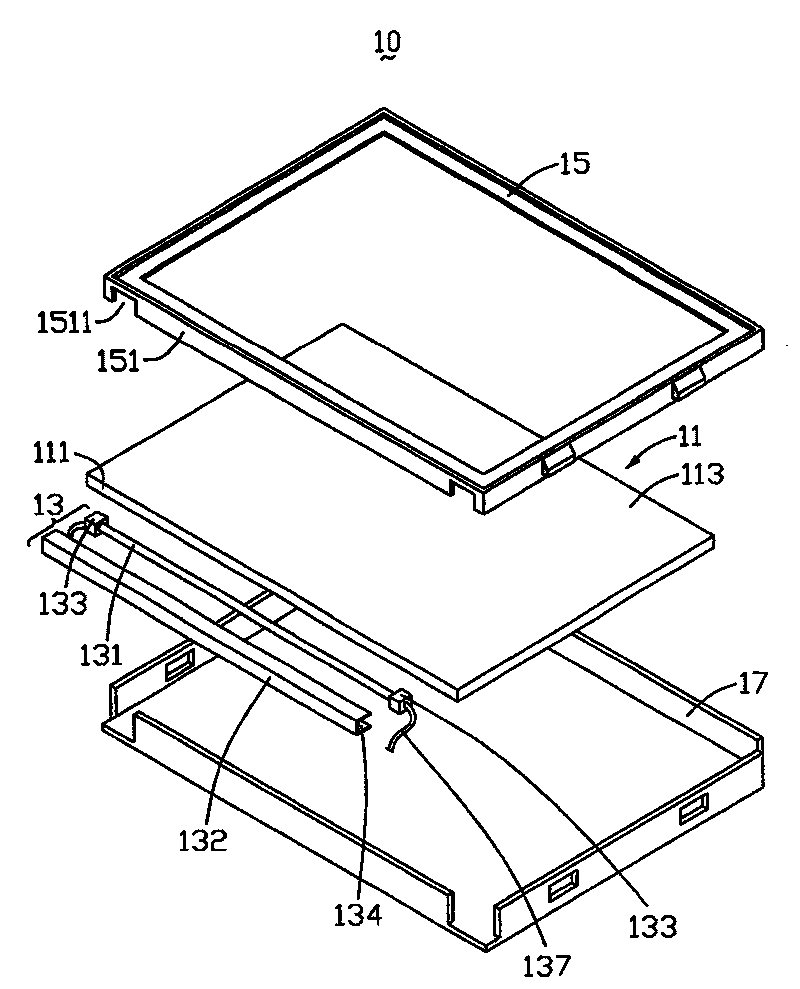

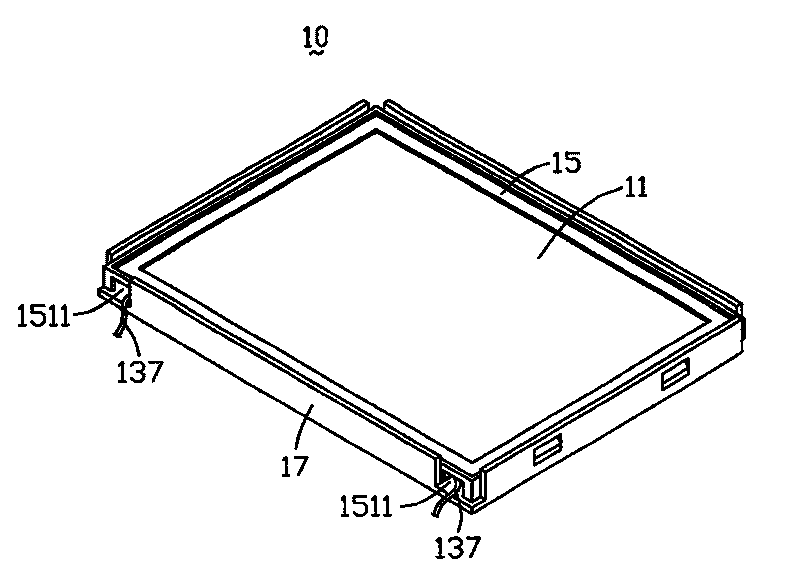

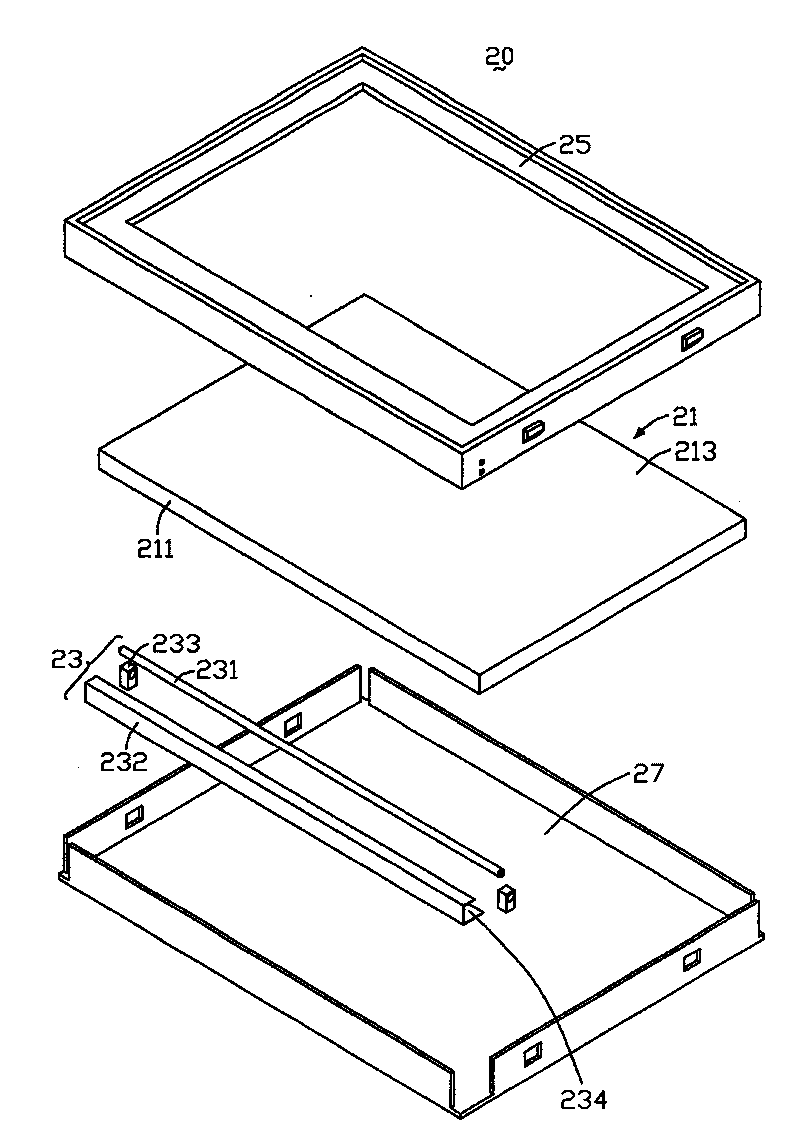

[0019] see image 3 , is a three-dimensional exploded schematic view of a preferred embodiment of the backlight module of the present invention. The backlight module 20 includes a bottom plate 27 , a lamp set 23 , a light guide plate 21 and a frame 25 . The bottom plate 27 cooperates with the frame 25 to accommodate the light guide plate 21 and the light tube set 23 .

[0020] The light guide plate 21 includes a light incident surface 211 and a light exit surface 213 adjacent to the light incident surface 211 . The light tube set 23 includes a light tube 231 , a light tube cover 232 surrounding the light tube 231 , and holding rubber sleeves 233 respectively sleeved on two ends of the light tube 231 . The lamp cover 232 has an opening 234 facing the light incident surface 211 of the light guide plate 21 .

[0021] see Figure 4 and Figure 5 , Figure 4 yes image 3 A three-dimensional schematic diagram of the frame 25 of the backlight module 20 flipped and rotated 90 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com