High brightness solid luminous subassembly manufacture method and luminous subassembly

A solid-state light-emitting and manufacturing method technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as the need to improve the refraction effect, and achieve the effects of varying depths, simplifying the process flow, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

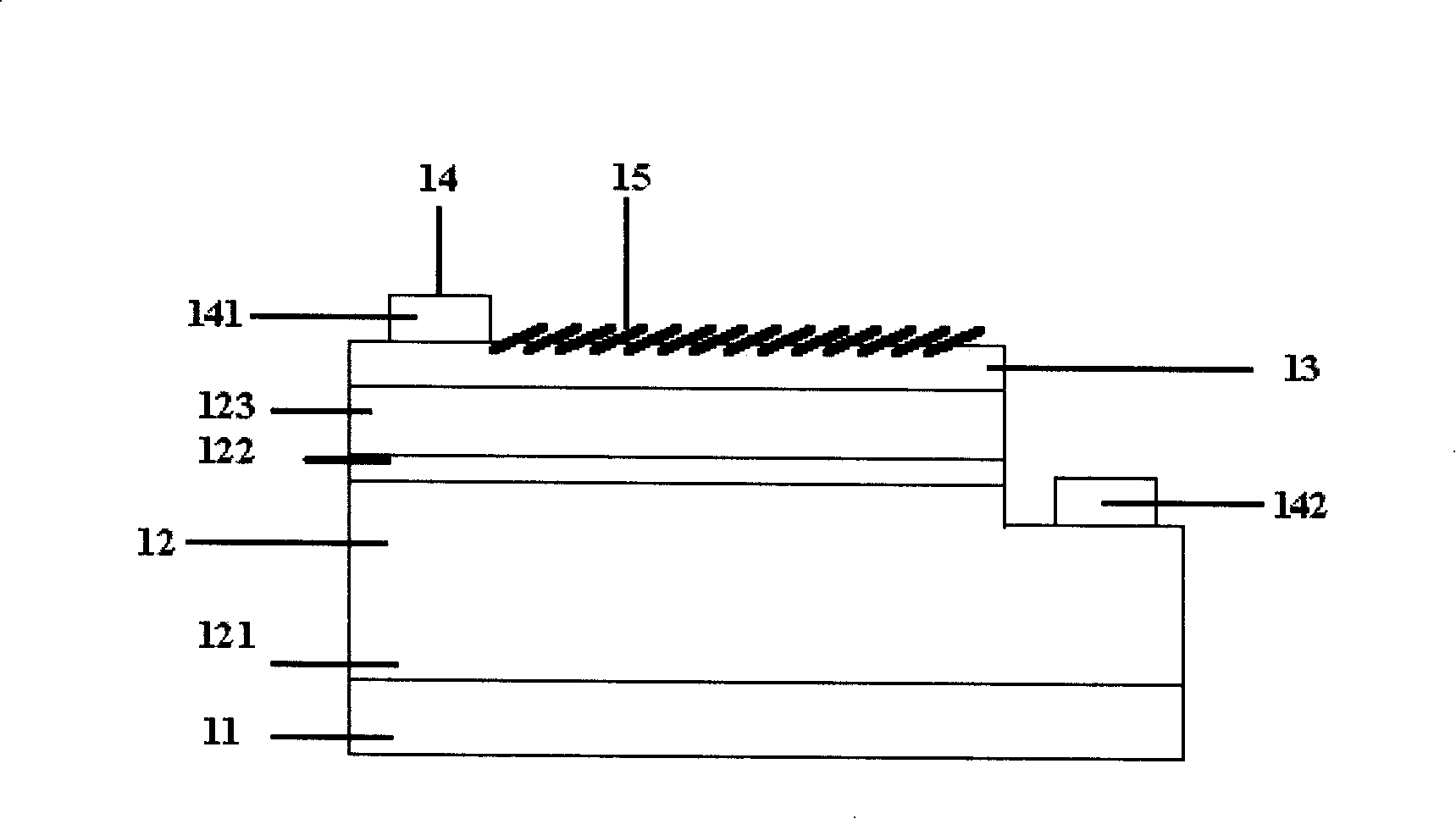

[0027] Example: see figure 1 , A method for manufacturing a high-brightness solid-state light-emitting component, which includes the following steps:

[0028] (1) A light-emitting unit 12 that can generate light is formed on the substrate 11, and the light-emitting unit includes an n-type batch coating layer 121, a light-emitting layer 122, and a p-type batch coating layer 123 to form the light-emitting unit 12;

[0029] (2) On the outer surface of the p-type batch coating layer 123 of the light-emitting unit 12 of the substrate 11, indium tin oxide is coated to form a transparent roughening unit 13;

[0030] (3) Prepare a selective etching solution that can chemically react with the material of the transparent roughening unit 13 and dissolve some of the components therein, and completely immerse the transparent roughening unit 13 on the substrate in the solution, and continue Take it out after more than 10 seconds;

[0031] (4) The outer surface of the transparent roughening unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com