Razor handle with improved grip structure

A handle and razor technology, applied in the field of ergonomic handles, can solve the problems of limited grip, inconvenient shaving and precise shaving, and achieve good shaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

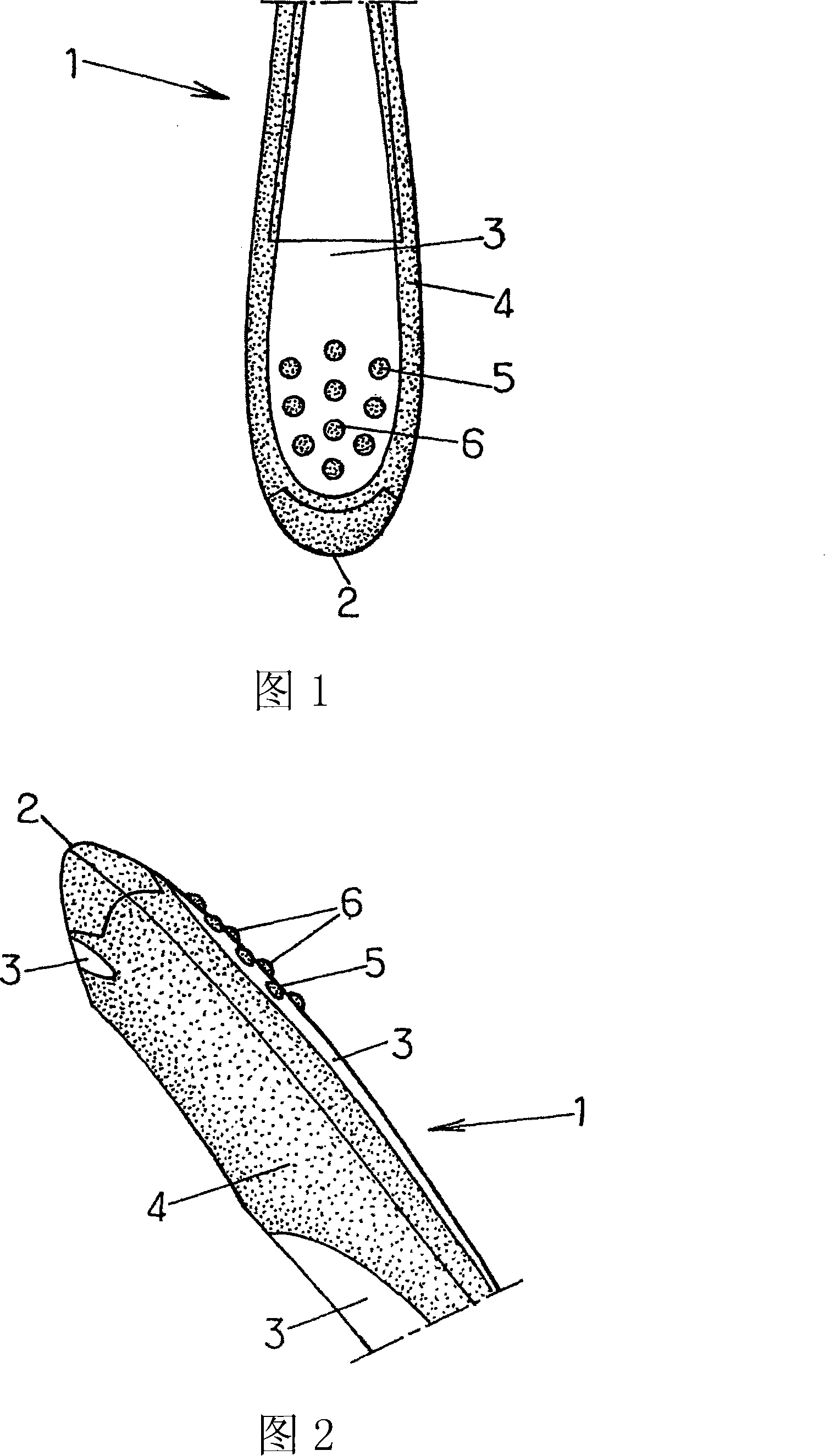

[0017] The subject of the present application is a handle with an improved grip structure for a wet or safety razor, said handle comprising a rigid plastic part and a compressible part, wherein said handle comprises a rubber protrusion provided on the upper side of the rear of the handle object, wherein the rubber protrusions protrude from the rigid plastic surface of the handle.

[0018] In the system of the present invention, the term "rubber" preferably refers to a resilient plastic material, more preferably a moldable resilient material such that it can be sufficiently compressed by the user without excessive force. Such material may be, for example, any elastic compound known in the art in any elastic hardness range, especially those suitable for making grips and those in the Shore A hardness range. This includes synthetic rubber and thermoplastic synthetic rubber and their blends. Suitable synthetic rubbers include nitrile rubber (NBR), styrene-butadiene rubber (SDR), e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com