Backlight module accurate light guide thin film core production method

A technology of backlight module and manufacturing method, which is applied in the direction of light guide, optics, laser, etc., can solve the problems of high technical requirements and great difficulty, and achieve the effects of high-efficiency light guide structure, process efficiency improvement, and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

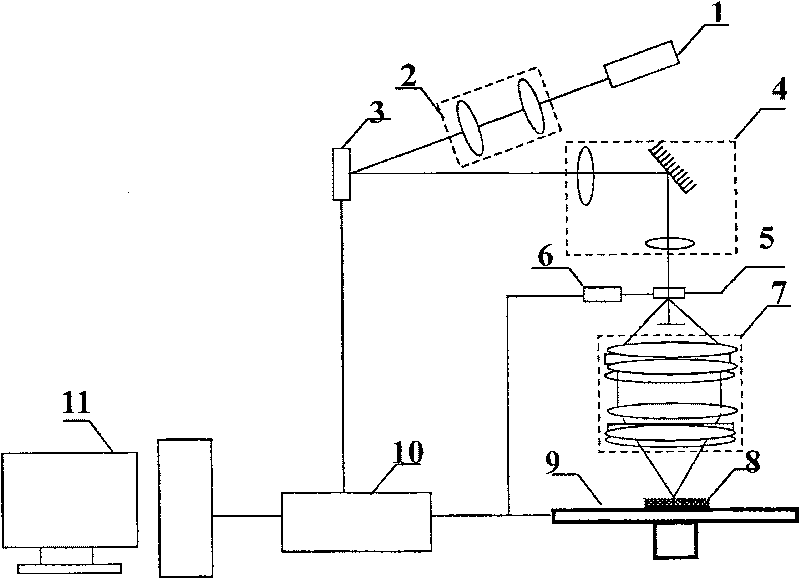

[0045] Example 1: see attached figure 2 As shown, a semiconductor-pumped solid-state laser (DPSSL) 1 is used, with ultraviolet light output (frequency tripled 351nm / 355nm), single pulse energy > 100uJ; On the mirror (DMD) 3, through the projection optical imaging system 4, the image input on the DMD is reduced, and the reduced magnification depends on the focal length ratio of the objective lens and the microscope; the reduced image is imaged on the back focal plane of the microscope. On the diaphragm 5, the function of the diaphragm is to block part of the stray light, which is controlled by the diaphragm controller 6; The photoresist dry plate 8 is set on the x-y precision work platform 9, and is controlled by the precision drive controller 10 to perform translational movement in the X-Y plane. The entire system is controlled and operated by the computer 11 .

[0046] The lens materials in the above laser etching system are all made of fused silica glass; the reflector is...

Embodiment 2

[0056] Embodiment 2: A semiconductor-pumped solid-state laser (DPSSL) is used, with ultraviolet light output (frequency tripled 351nm / 355nm), and single pulse energy>100uJ. The laser beam emitted from the laser goes through the beam expansion and collimation optical path, and illuminates on the digital micro-mirror (DMD). Through the projection optical system, the input pattern on the DMD is reduced. The reduction ratio depends on the focal length ratio of the objective lens and the microscope. The reduced image is imaged on the diaphragm of the back focal plane of the microscope, the function of the diaphragm is to block part of the stray light. Then, the small pattern near the diaphragm is imaged on the SU-8 photoresist dry plate through the 4F lens group. The shape of the light spot or the light intensity distribution in the light spot can be changed by changing the shape of the graphics input on the DMD and the difference in gray level, so that the dots with different surf...

Embodiment 3

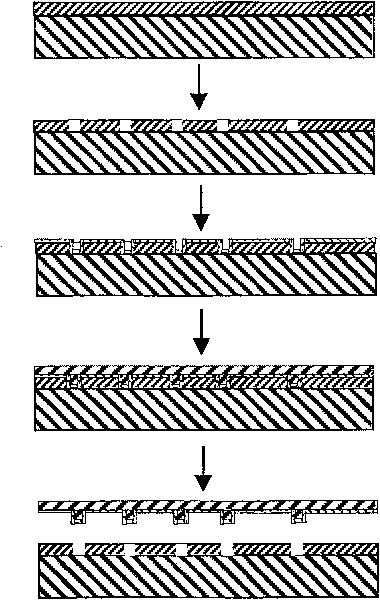

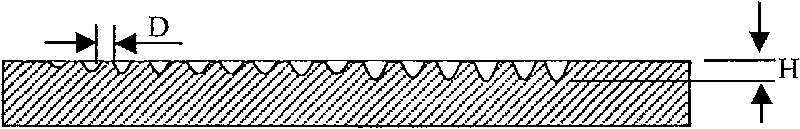

[0057] Embodiment 3: Take the production of the light guide plate of the mobile phone display screen as an example, see the attached Figure 5 , the process steps of making the light guide plate (film) mold core of the present invention are described in detail. (1) Design and determine the light guide structure area according to the application requirements, draw the pattern, use the network point design software to design the network point distribution of the light guide area according to the characteristics of the light source, and use the optical simulation software to evaluate the brightness and uniformity of the designed network point. do further optimization. Determine parameters such as dot size and depth. (2) Convert the designed dot distribution and dot parameters into controllable files of laser etching equipment. (3) Adjust the optical path of the laser etching equipment, set the corresponding parameters, and perform etching on the SU-8 dry plate. (4) Carry out d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com