Movable hoisting device supporting leg and movable hoisting device with the supporting leg

A mobile lifting and lifting equipment technology, applied in the direction of cranes, etc., can solve problems such as downward bending, oil cylinder failure, and manufacturing difficulties, and achieve the effect of reducing the subsidence of lifting equipment, reducing the degree of subsidence, and reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

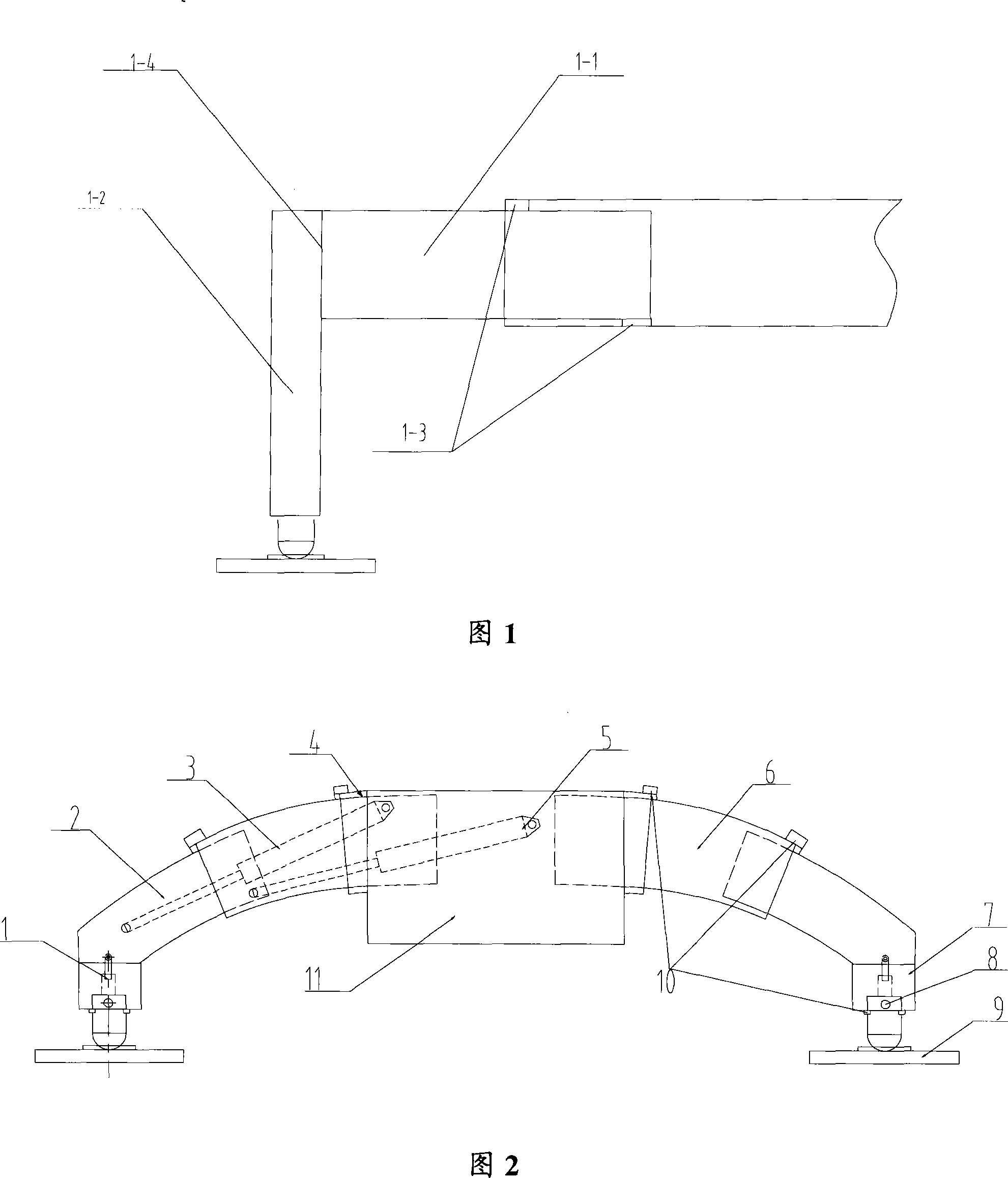

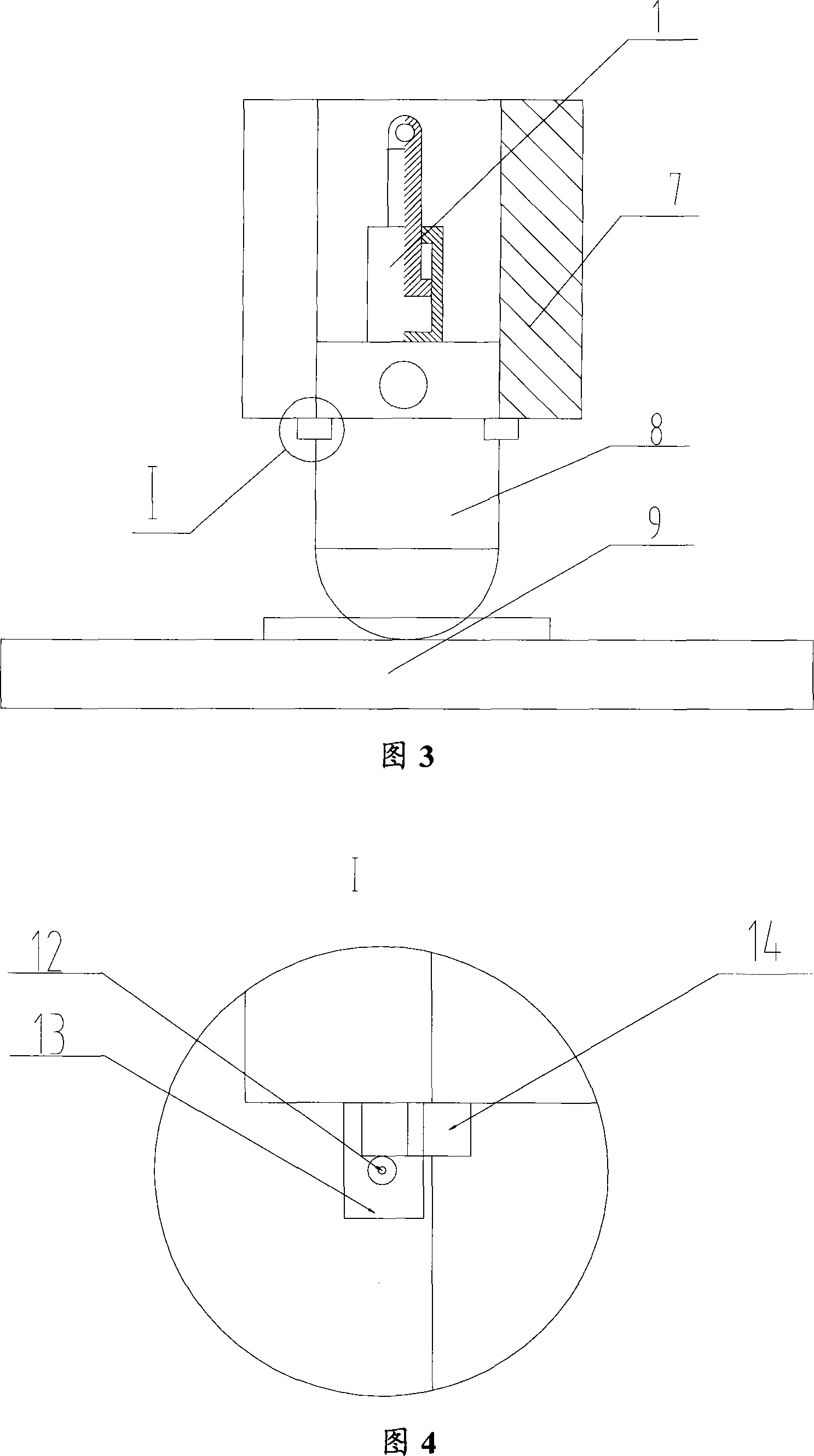

[0029] Please refer to FIG. 2 , which shows a structural view of the legs of the movable lifting device provided by the embodiment of the present invention. The structure of the outrigger is left-right symmetrical, and only the names of the parts on one side are marked in the figure, and the parts on the other side are mentioned with the same names and labels.

[0030] As shown in the figure, on the vehicle frame 11, a fixed leg box 4 is fixed thereon by welding or other means, and the fixed leg box 4 is a hollow box-shaped structure, which protrudes from the vehicle frame 11 to provide Fixed foundation.

[0031] The first-level movable leg section 6 is socketed in the fixed leg box 4, and the first-level movable leg section 6 is an arc-shaped hollow box whose outer periphery matches the inner periphery of the fixed leg box 4, and can be The box body of described fixed leg box 4 expands and contracts. In this primary movable leg section 6, the secondary movable leg section 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com