Application method of novel post-tensioned pre-stress soil blocking pile

A post-tensioning and retaining pile technology, applied in the field of retaining piles, can solve the problems of steel strength restriction and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

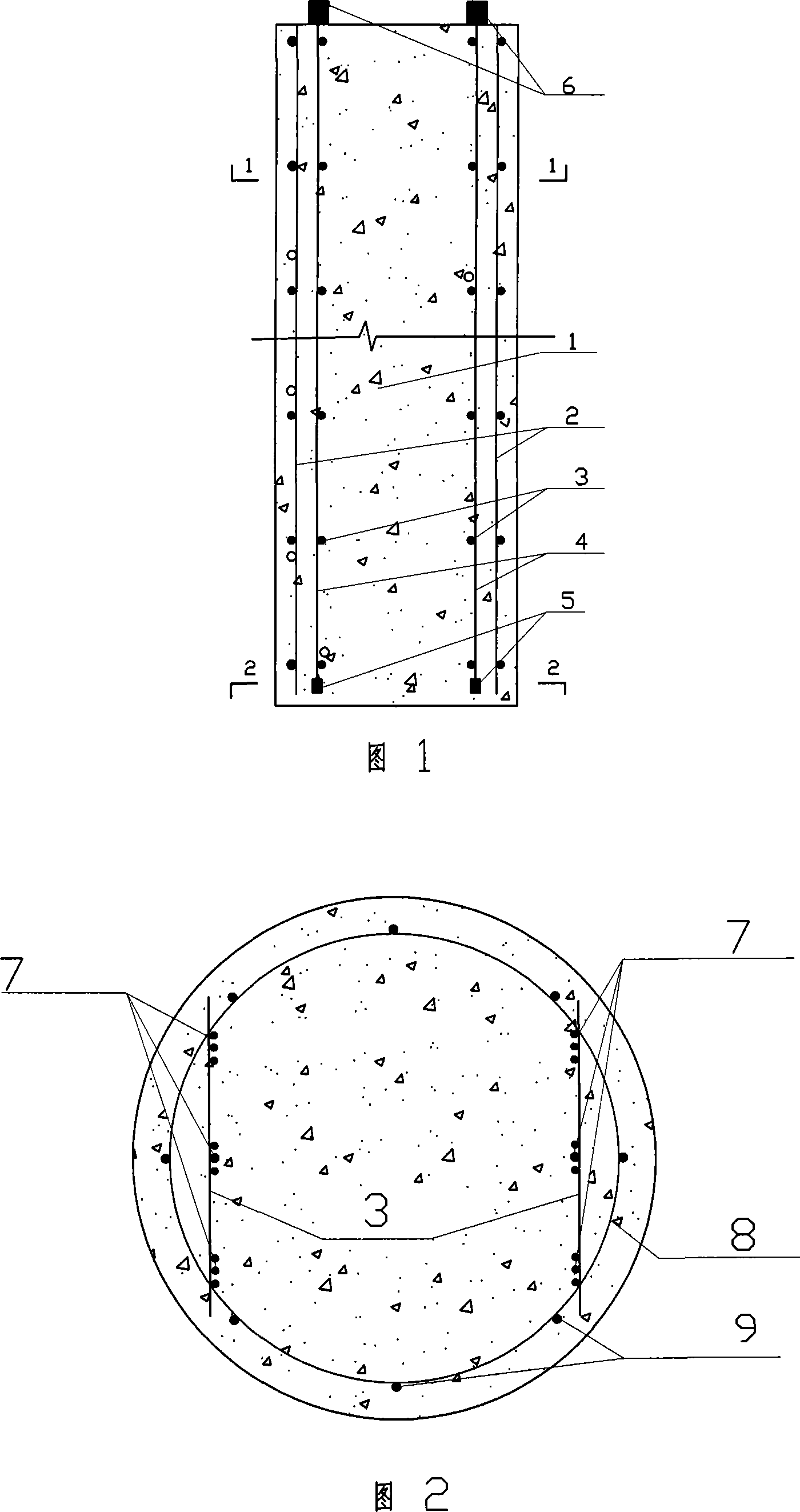

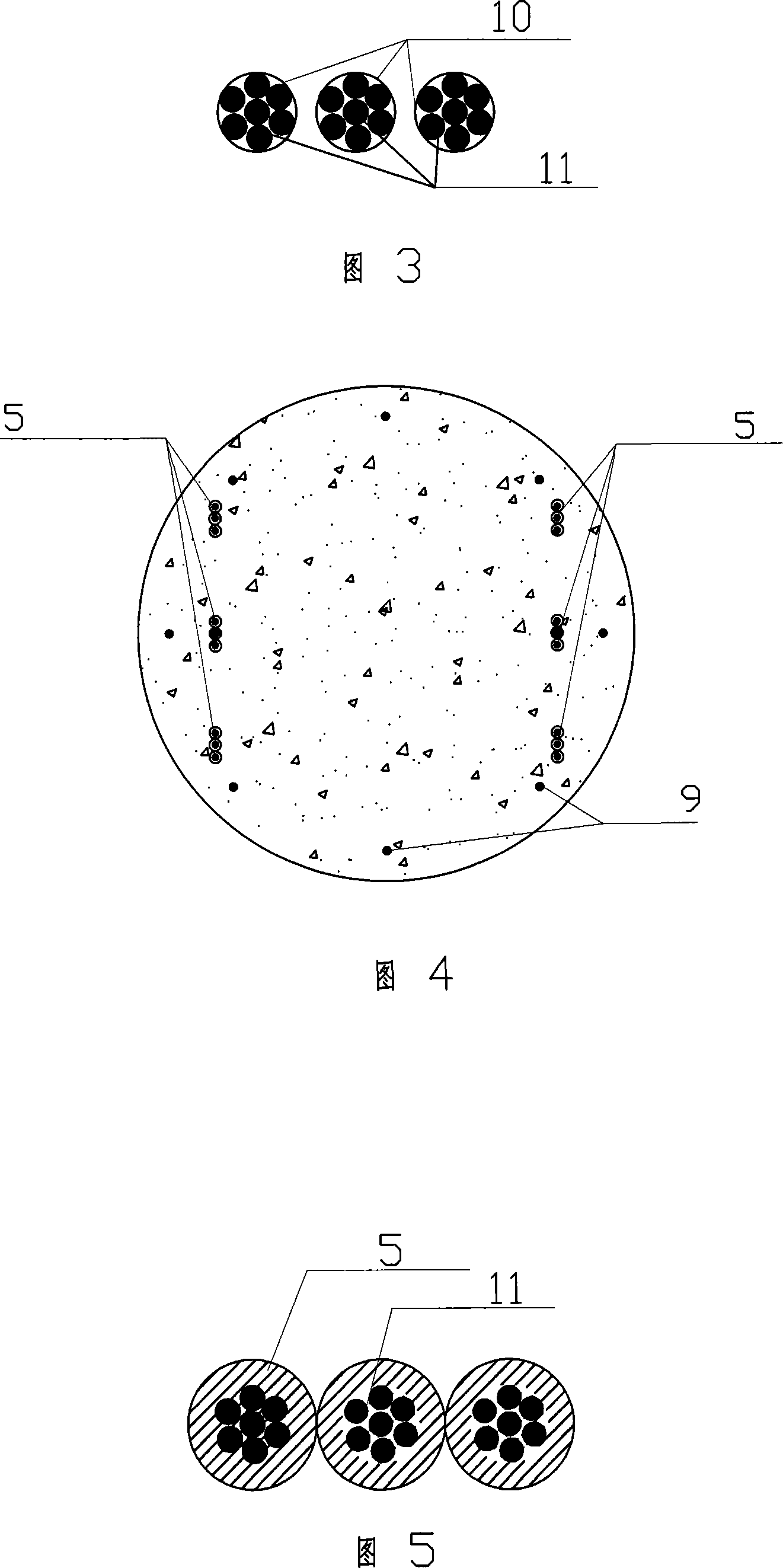

[0013] Referring to Figures 1 to 5, (a) Calculate the number and location of reinforcement and steel strands for the pile according to the stress conditions of the retaining pile; (b) Make holes for the retaining pile; (c) Make the reinforcement cage ; (d) Arrange steel strands in a certain direction on the reinforcement cage, and install the anchor head at the bottom of the pile; (e) Put the reinforcement cage configured with steel strands into the pile hole according to the predetermined direction, and fix it; (f ) Pour the pile concrete, and wait for it to reach the strength required for prestress; (g) install the pile top anchor, apply prestress to the steel strand according to the design value, and lock it; (h) seal the anchor head of the pile top for protection , the process is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com