Rail measuring vehicle of bridge-type crane

An overhead crane and measuring vehicle technology, which is applied to measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of many hidden dangers and low work efficiency, improve reliability, eliminate hidden dangers to personal safety, and measure The time spent improves the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

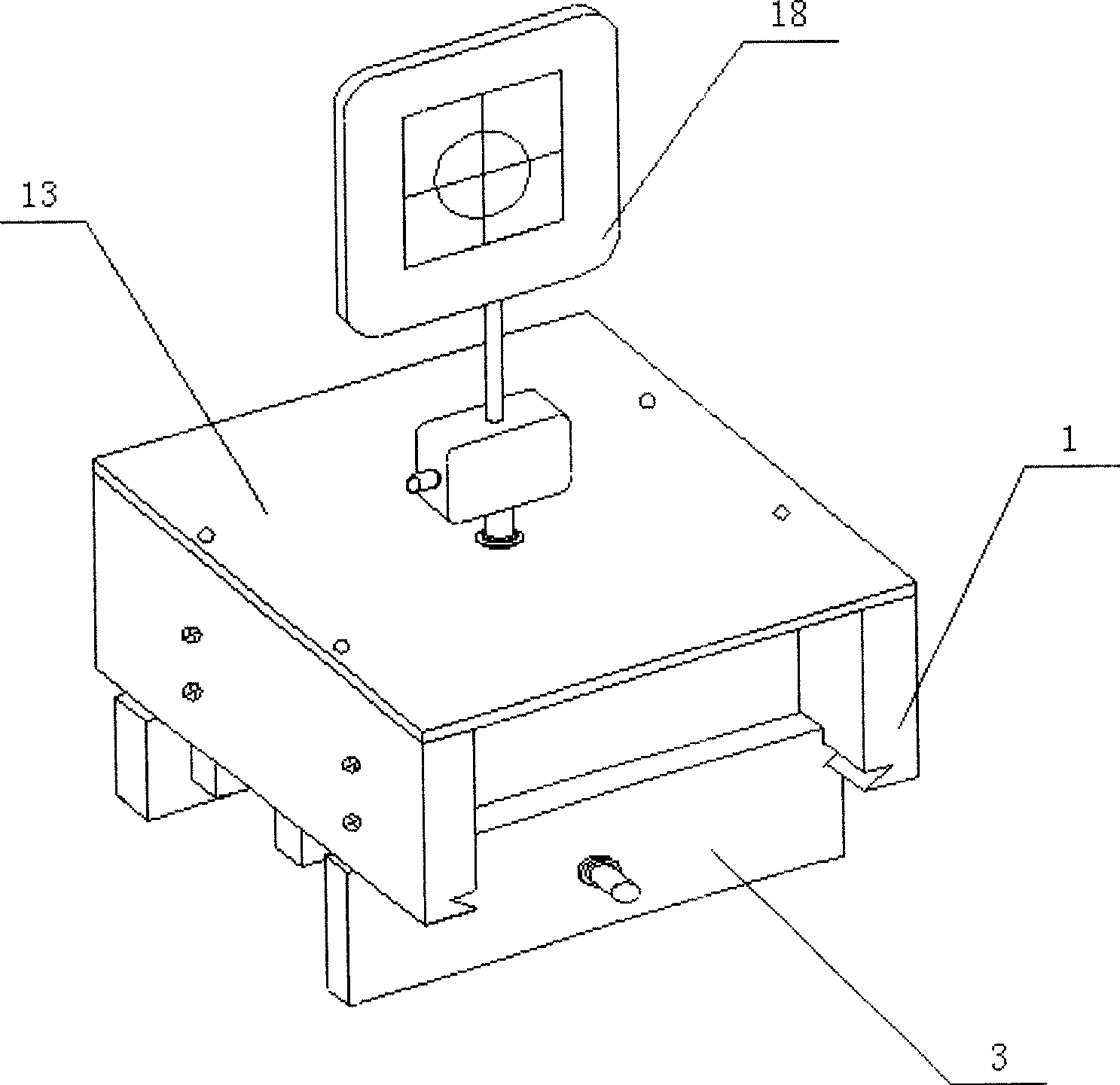

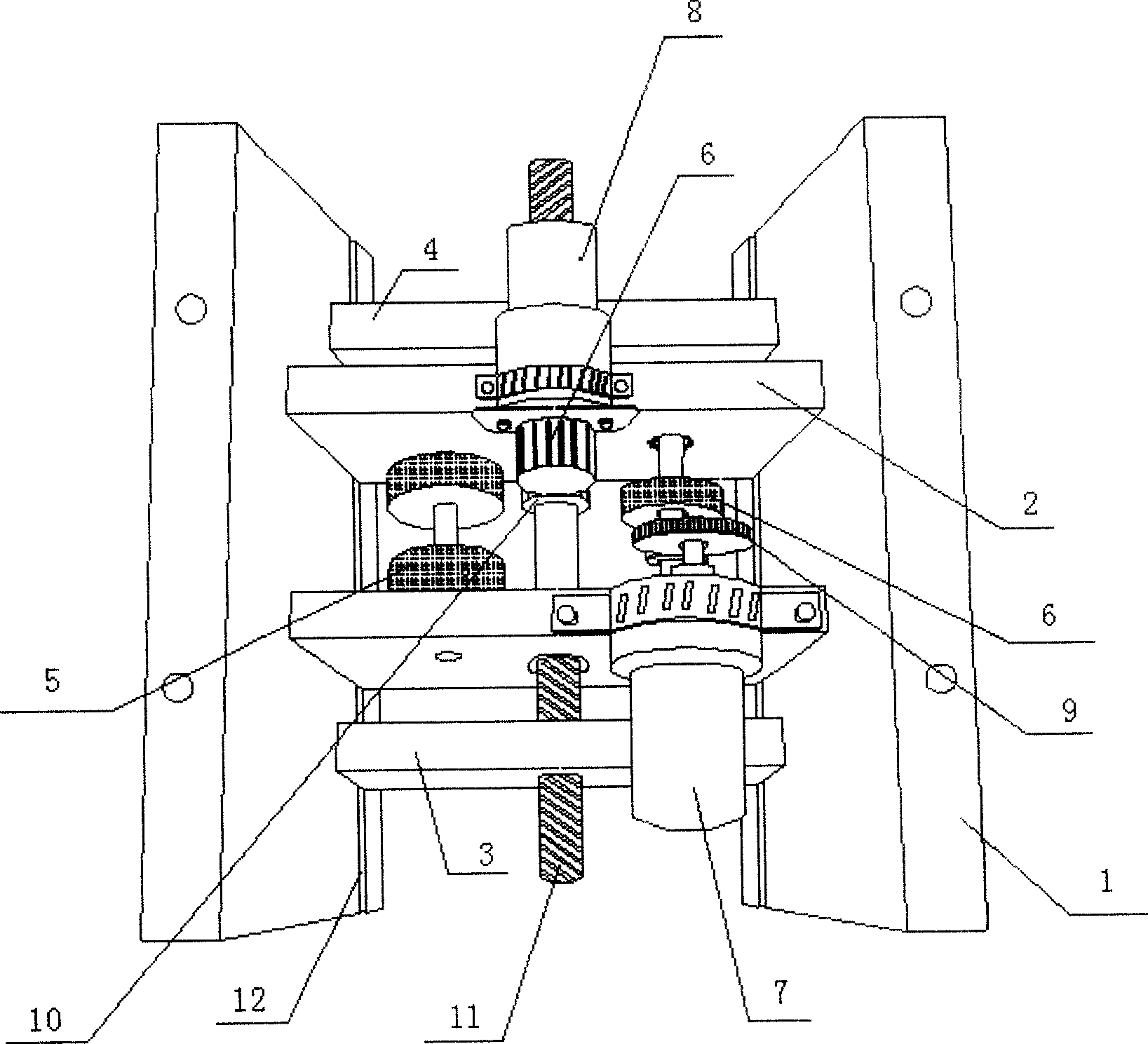

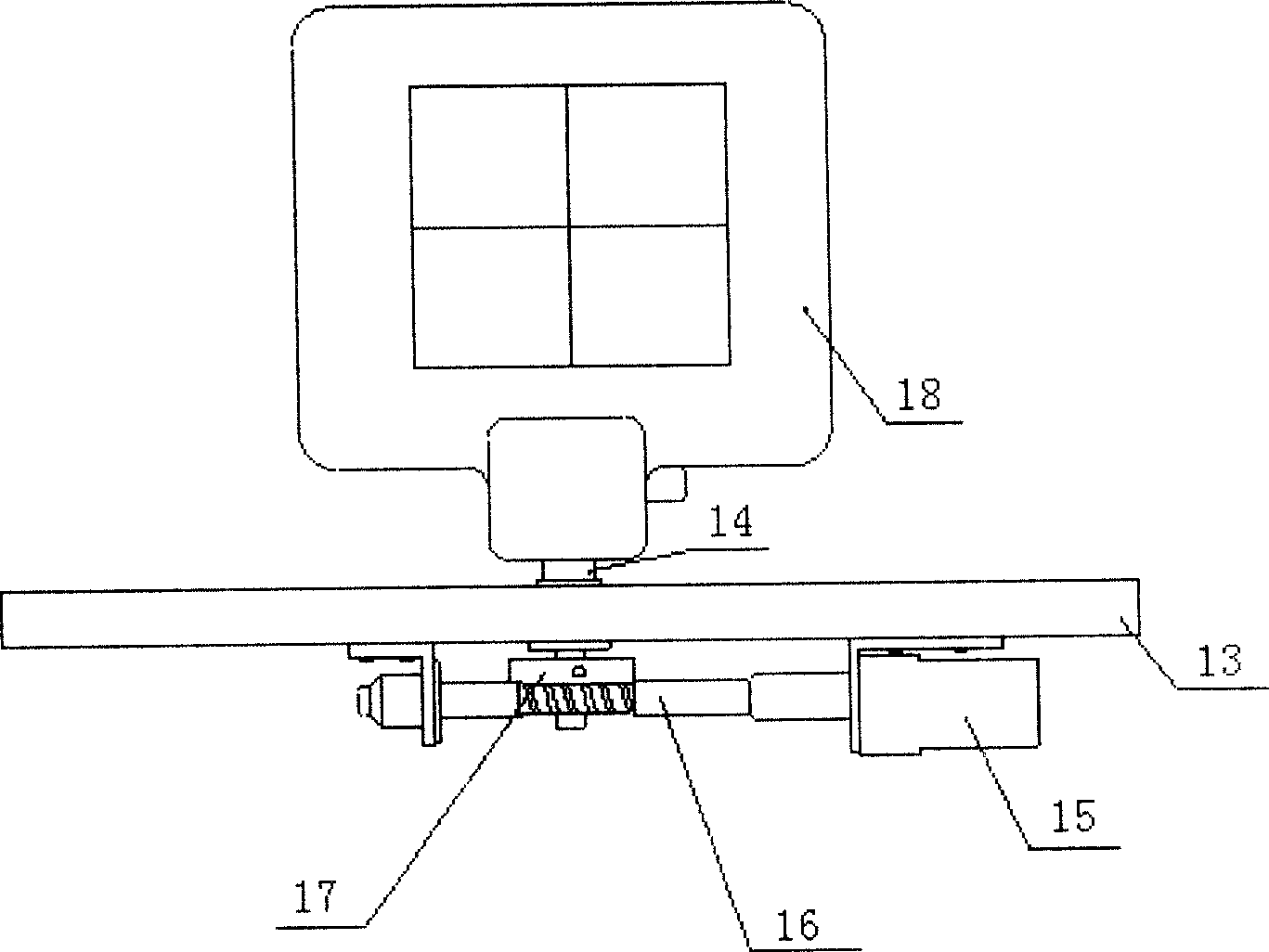

[0021] As shown in the figure, this bridge crane track measuring vehicle includes a remote control mechanism, a traveling mechanism, a fastening mechanism and a direction adjustment mechanism arranged on the main frame. It is characterized in that: the main frame is composed of a group of parallel Front and rear support 1 and the left and right supports 2 that are connected between the two form a well-shaped frame; the described walking mechanism is composed of a walking drive motor 7 mounted on a left and right support 2 and a set of left and right supports to match it. The drive wheel assembly consists of a drive shaft arranged between the two left and right brackets and a set of drive wheels 6 fixed on the drive shaft, and is driven by another transmission gear on the drive shaft and travel. The walking transmission gear 9 at the output shaft end of the motor 7 is engaged; the fastening mechanism is composed of another fastening drive motor 8 arranged on the left and right b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com