Coke oven tamping machine for tests and uniform density control method thereof

A tamping machine, a technology for testing, applied in coking ovens, mechanical treatment of coal loaded into the furnace, petroleum industry, etc., can solve the problems of high labor intensity, safety hazards, personal injuries, etc., and reduce labor intensity , high degree of automation, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

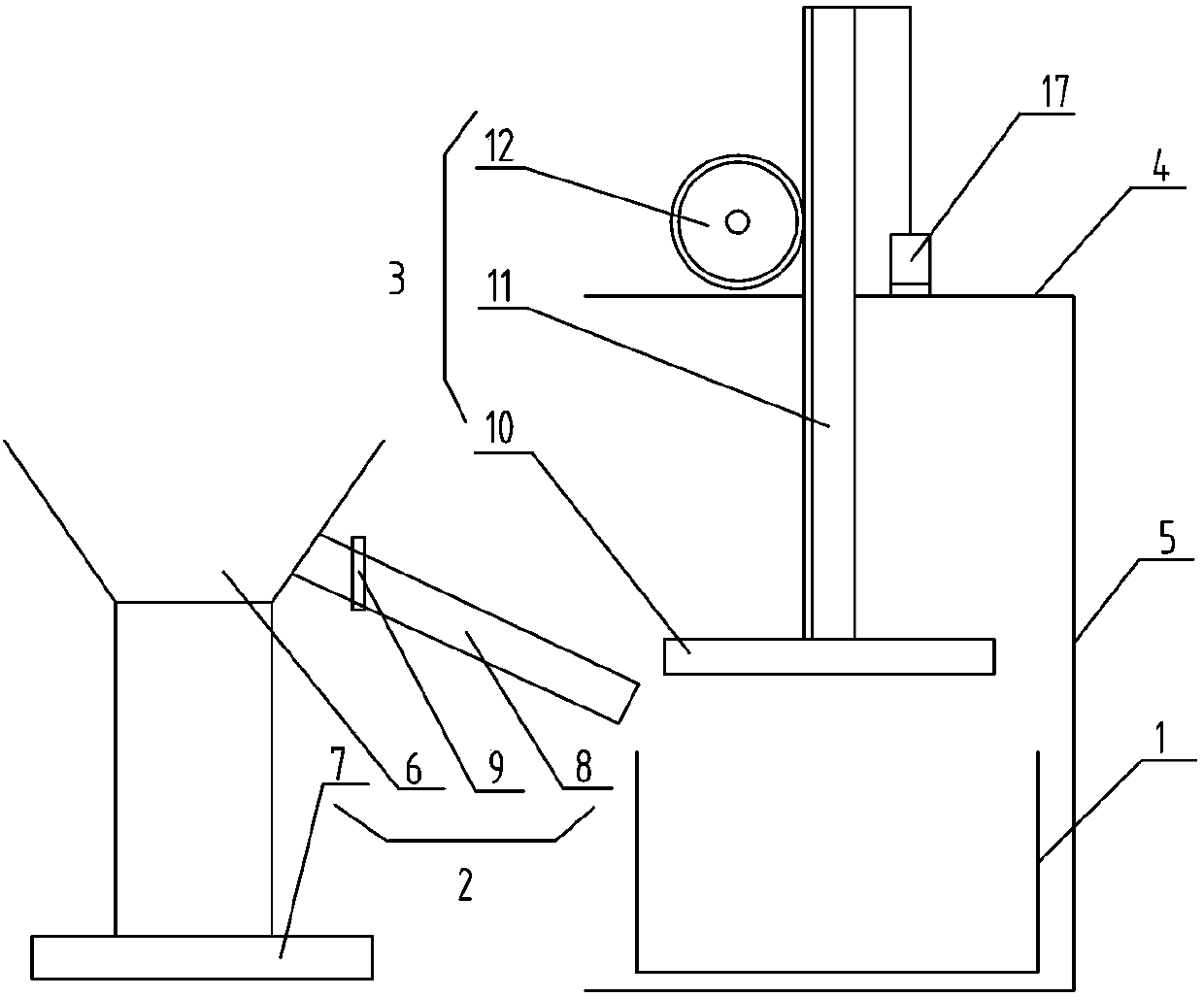

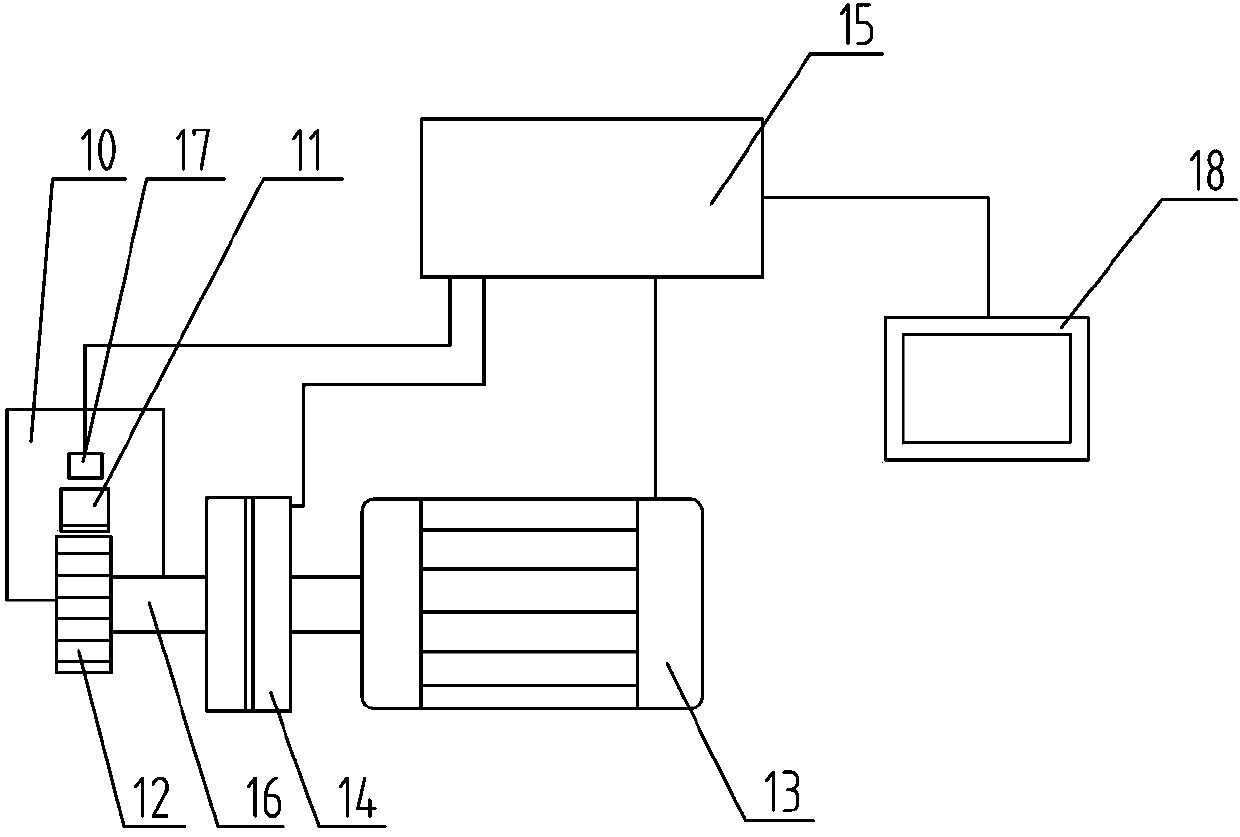

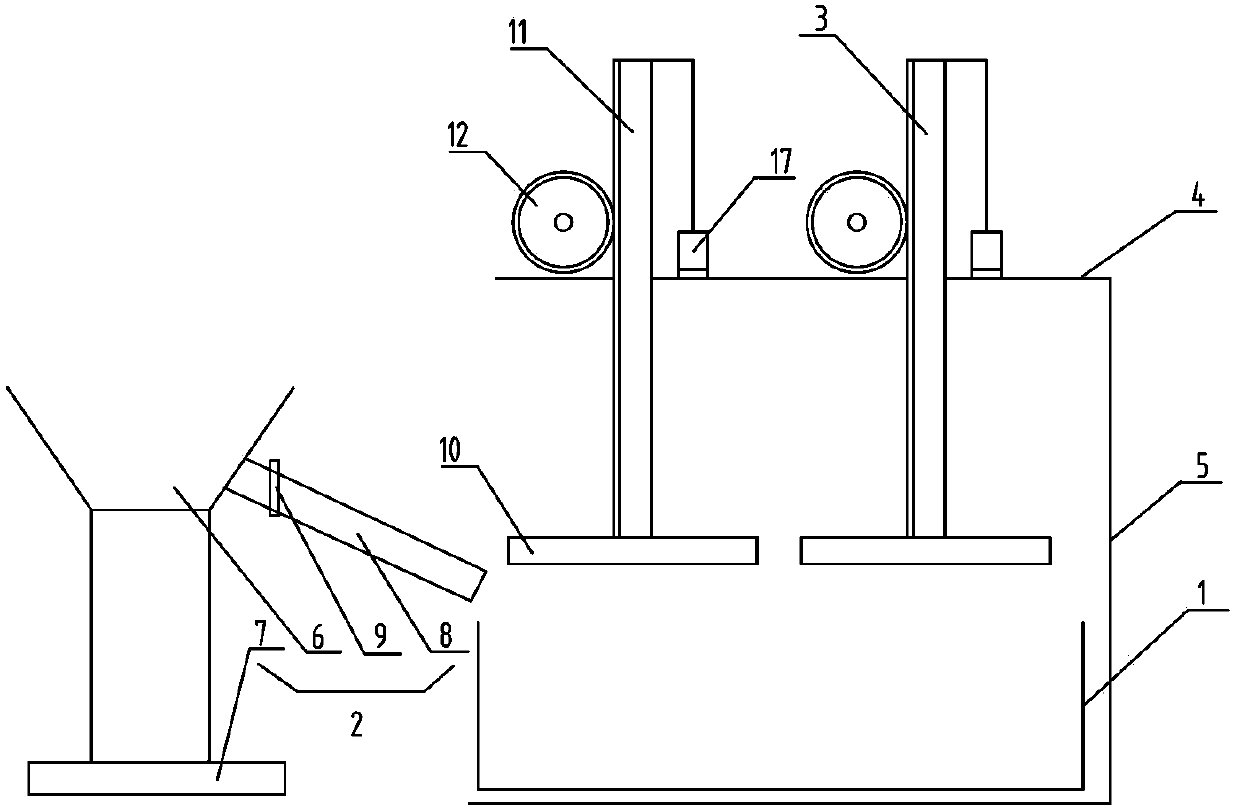

[0029] See figure 1 , figure 2 , is a structural schematic diagram of the first embodiment of a test coke oven tamping machine of the present invention. This is a single hammer head structure, which is suitable for occasions with a processing capacity of 40kg or less, and includes a coal box 1, a quantitative coal loading device 2 and a tamping The tamping mechanism 3 is located on the upper beam 4 and is integrated with the coal box 1 through the frame 5. The quantitative coal loading device 2 is located on one side of the coal box 1. The quantitative coal loading device 2 includes a sample silo 6 , electronic scale 7, feeding pipe 8 and feeding electric control valve 9, realize quantitative feeding, tamping mechanism 3 comprises tamping hammer 10, rack 11, gear 12, motor 13, electromagnetic clutch 14 and controller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com