Movable copper and lead hoisting device

A mobile and hoist technology, applied in the field of lead lifting device and mobile copper, can solve the problems of workers' personal safety hazards, high labor intensity and low work efficiency, and achieve the elimination of personal safety hazards and workers' labor intensity. Small, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

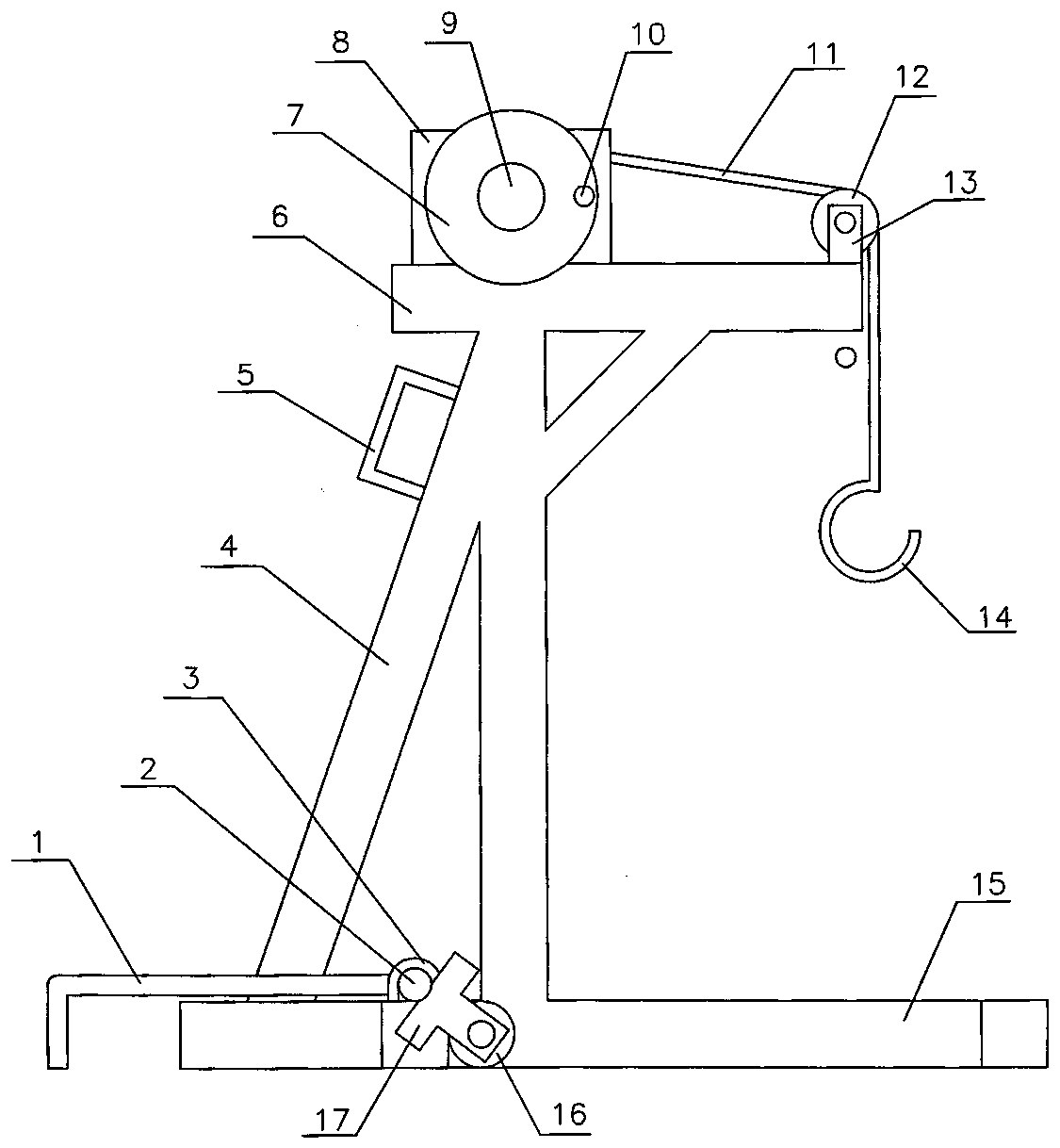

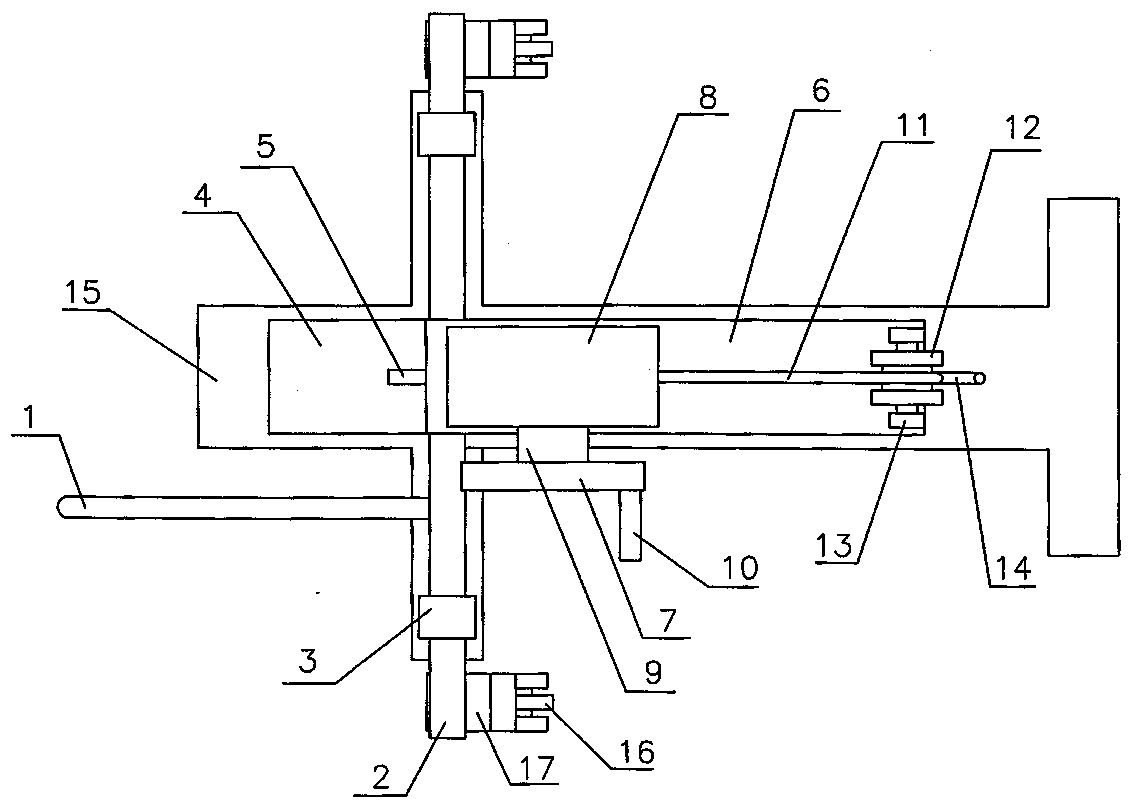

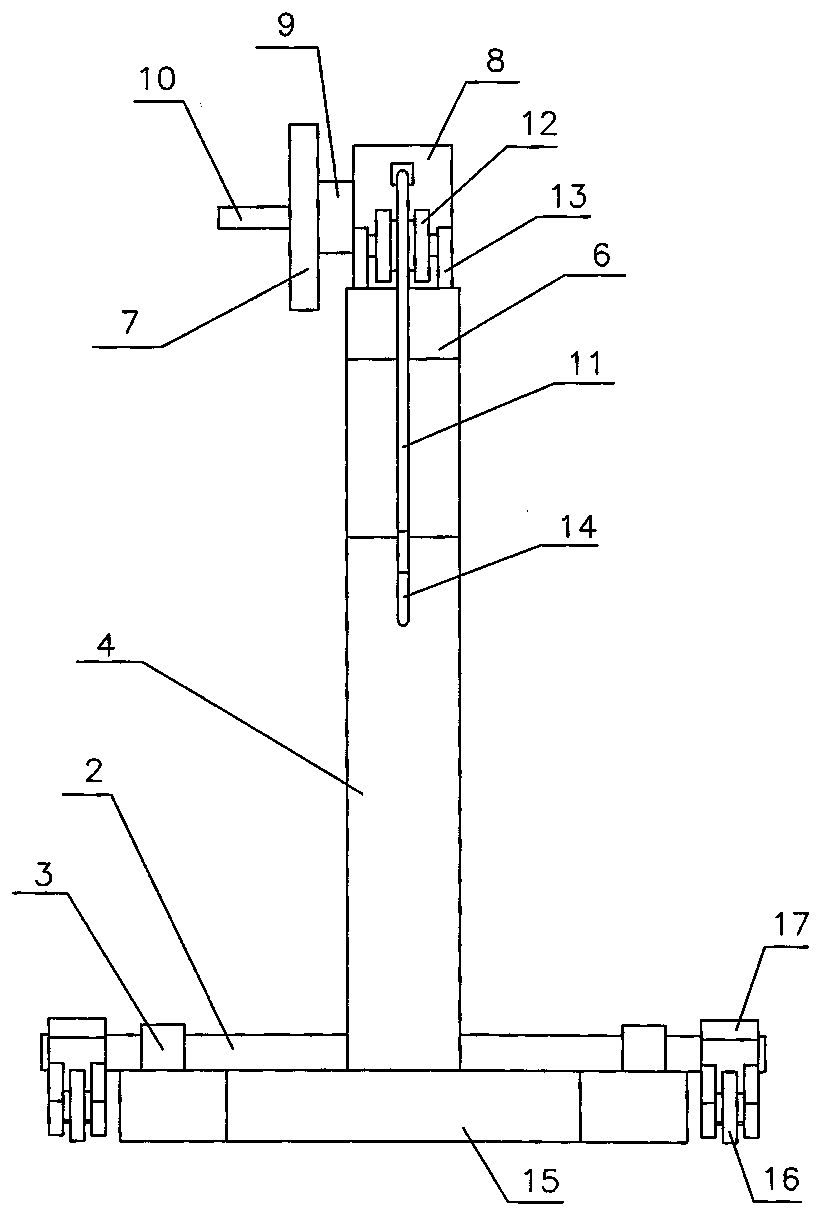

[0019] exist figure 1 , figure 2 , image 3 In the shown embodiment, the bracket is composed of a beam 4, a top plate 6, and an underframe 15. There is an armrest frame 5 on the beam 4; there are two shaft buckles 3 on the bottom frame 15, and the two shaft buckles 3 are encased on the shaft 2, and the shaft The two ends of 2 respectively weld a wheel frame 16, wheel frame 16 is equipped with wheels 17, and the middle part of axle 2 welds rotating rod 1. Hanging gourd 8 and pulley frame 12 are housed on the top plate 6, and one end of the hanging gourd shaft 9 in the hanging gourd 8 stretches out of the hanging gourd 8, and the rotating disk 7 is contained on the hanging gourd shaft 9, and a handle 10 is arranged on the rotating disk 7; Pulley 13 is arranged, and sling 11 is placed on the pulley 13, and the two ends of sling 11 are connected with hoist 8, hook 14 respectively.

[0020] When the temperature in the copper and lead material car falls below the solidification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com