Vibration type driving apparatus

A driving equipment, vibration type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of insufficient reduction of ultrasonic actuator size, vibration components Or the complex shape of the moving components, and it is not easy to manufacture ultrasonic actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Several exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] A vibration-type driving device according to an exemplary embodiment of the present invention is suitable for an ultrasonic linear motor that drives a moving member in contact with the vibrating member using vibration excited in the vibrating member.

[0030] first exemplary embodiment

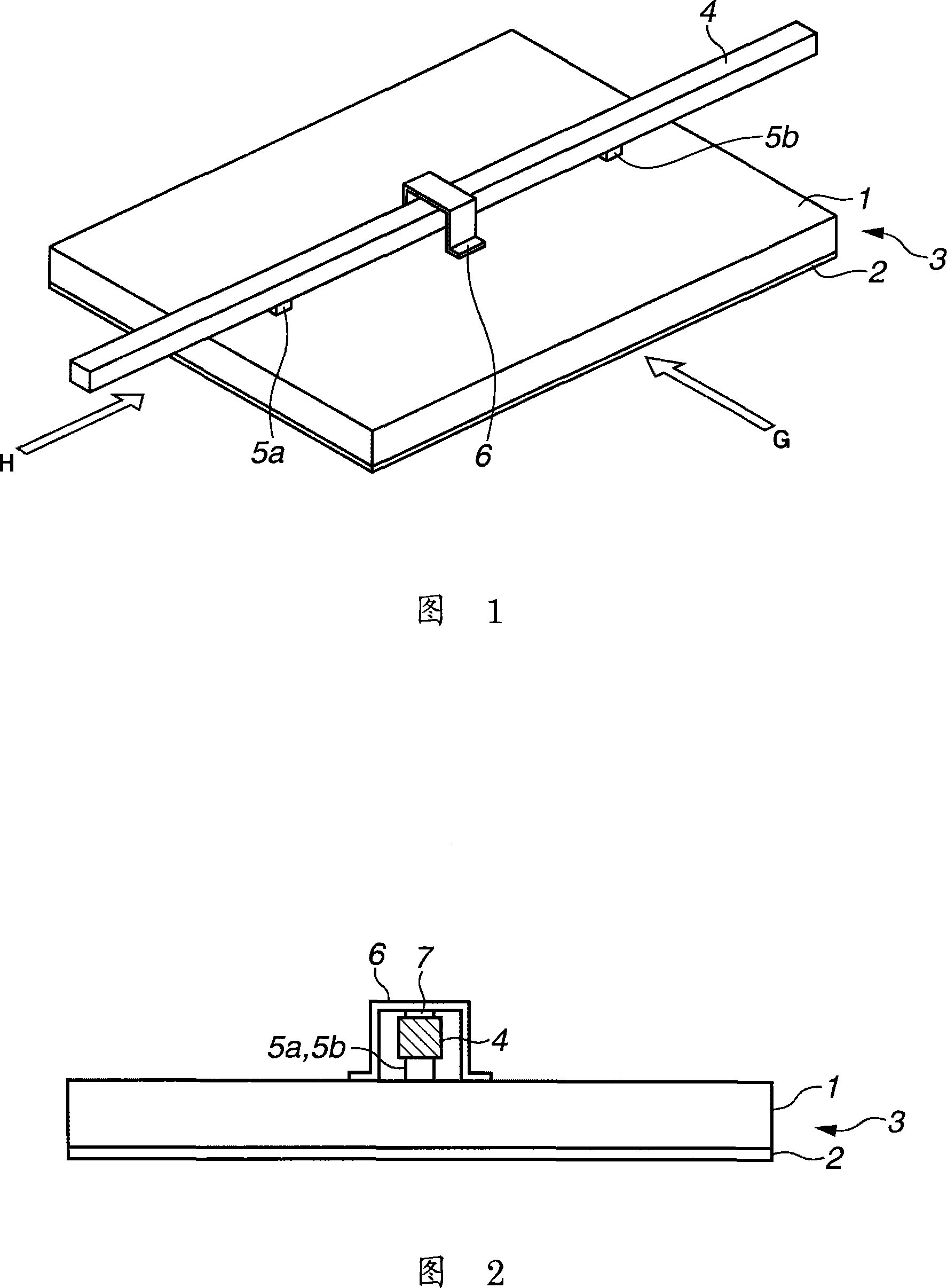

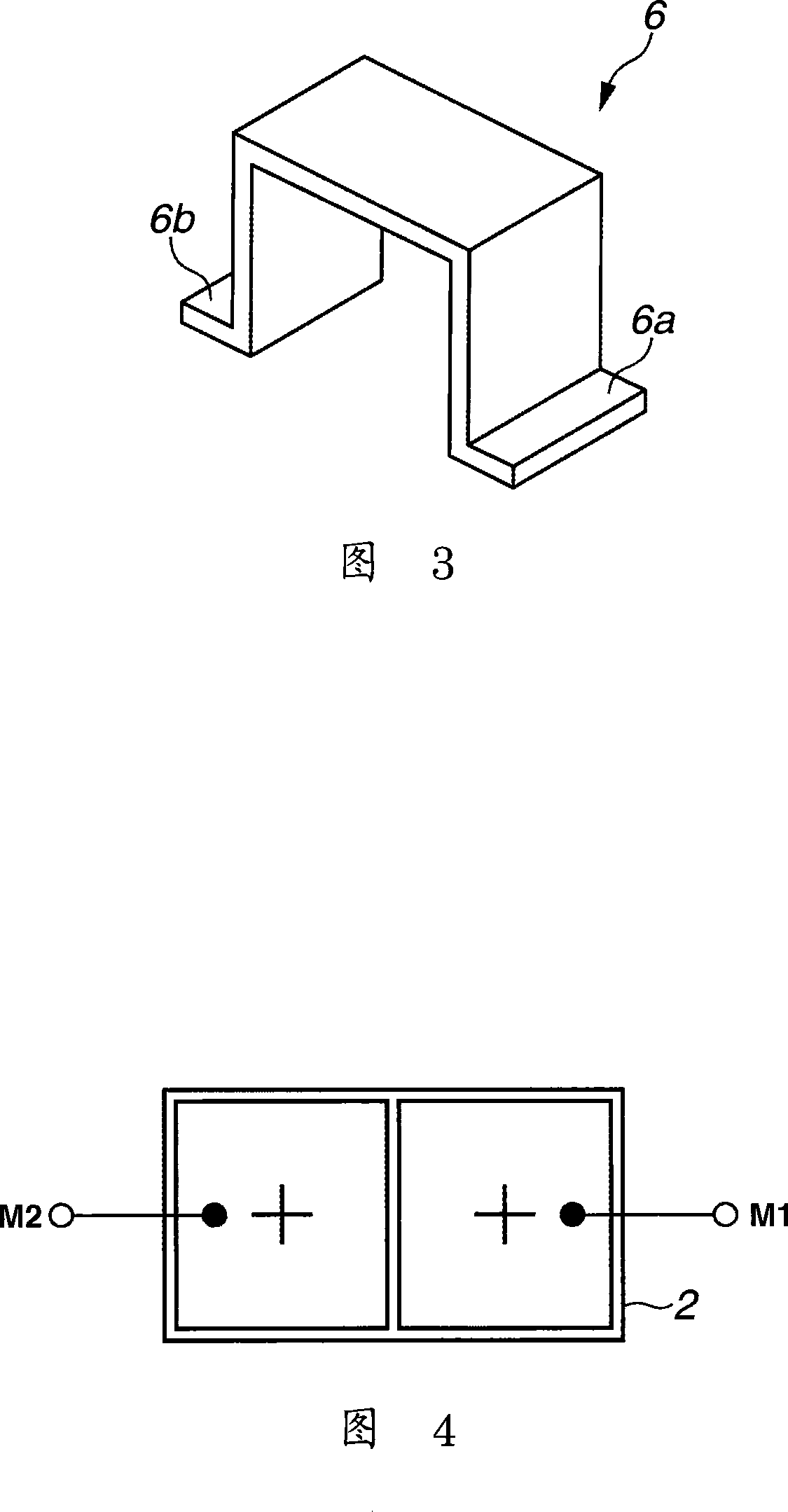

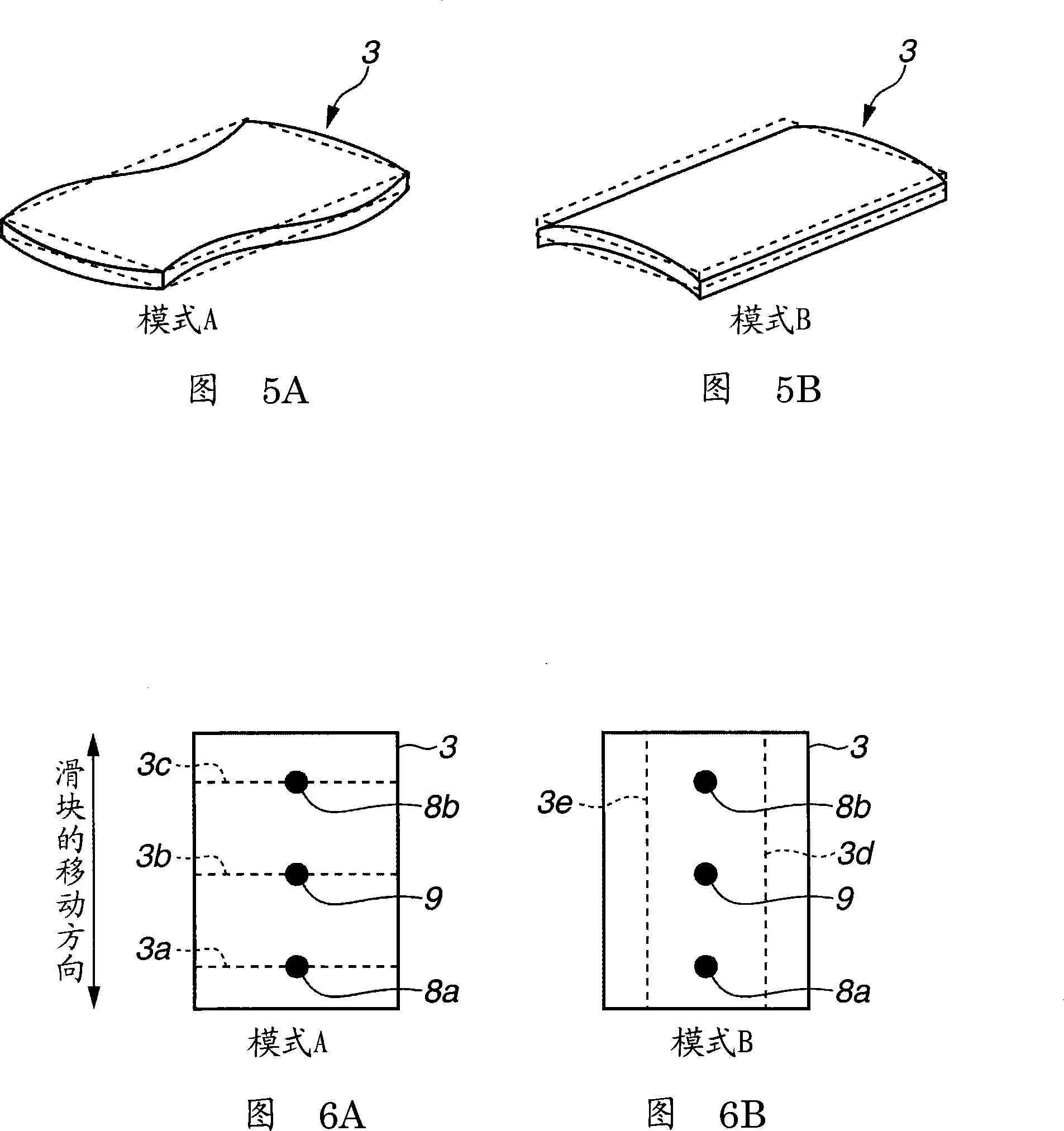

[0031] FIG. 1 is a perspective view illustrating the configuration of an ultrasonic linear motor according to a first exemplary embodiment of the present invention. FIG. 2 illustrates a cross-sectional view of the ultrasonic linear motor when viewed in the direction of arrow H in FIG. 1 . The ultrasonic linear motor includes a vibrating member 3 formed of a rectangular flat plate material and a slider 4 (ie, a sliding member) that moves relative to the vibrating member 3 . The ultrasonic linear motor also includes a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com