High-precision optical tiny thrust measurement system based on two-beam interference principle

A double-beam interference and measurement system technology, which is applied in the field of engine micro-thrust measurement devices and engine thrust measurement devices, can solve the problems of high friction-free requirements at the joints of components, a large number of sensors, complex systems, etc., and achieve easy replacement and maintenance. Measuring Precise, Wide-Source Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

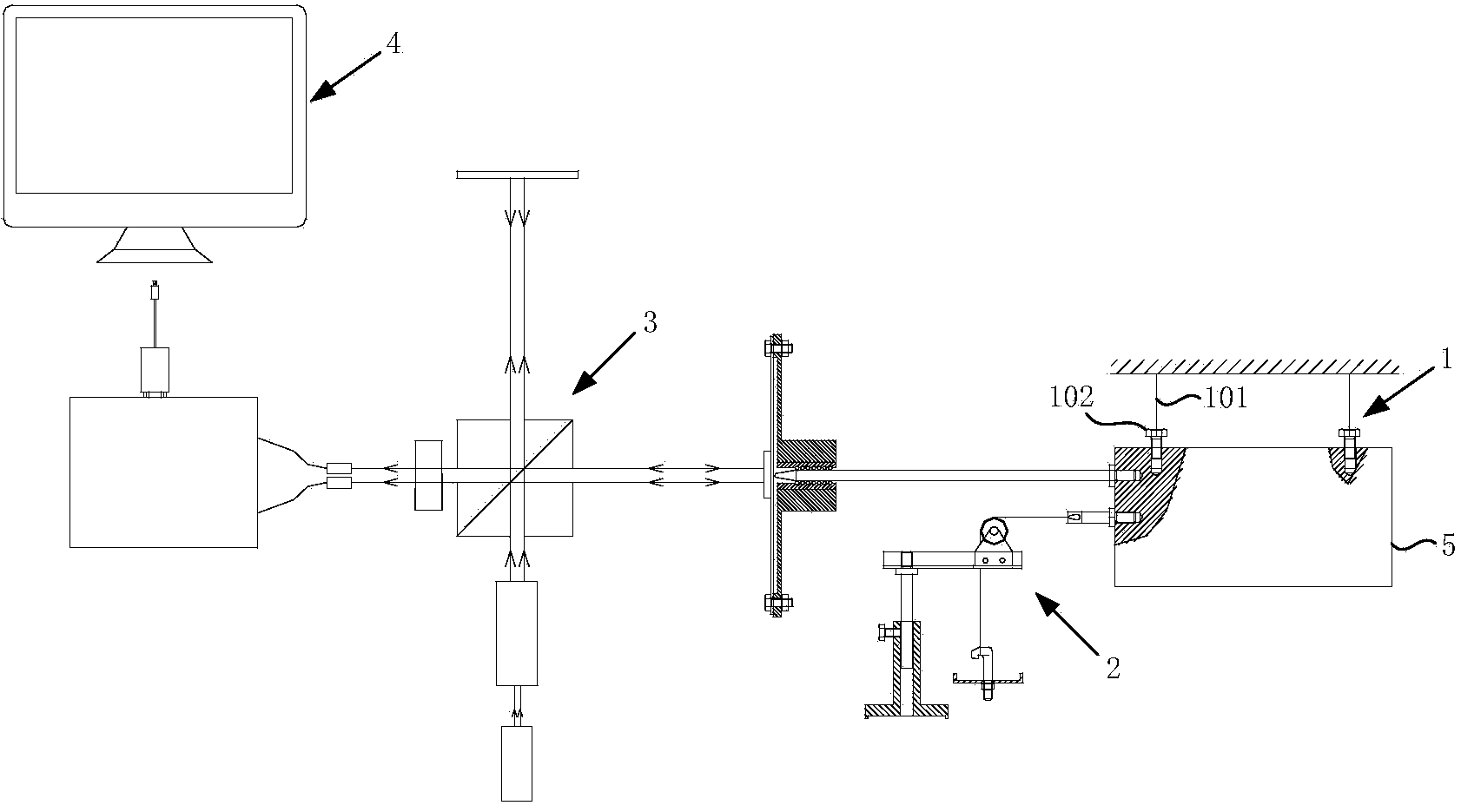

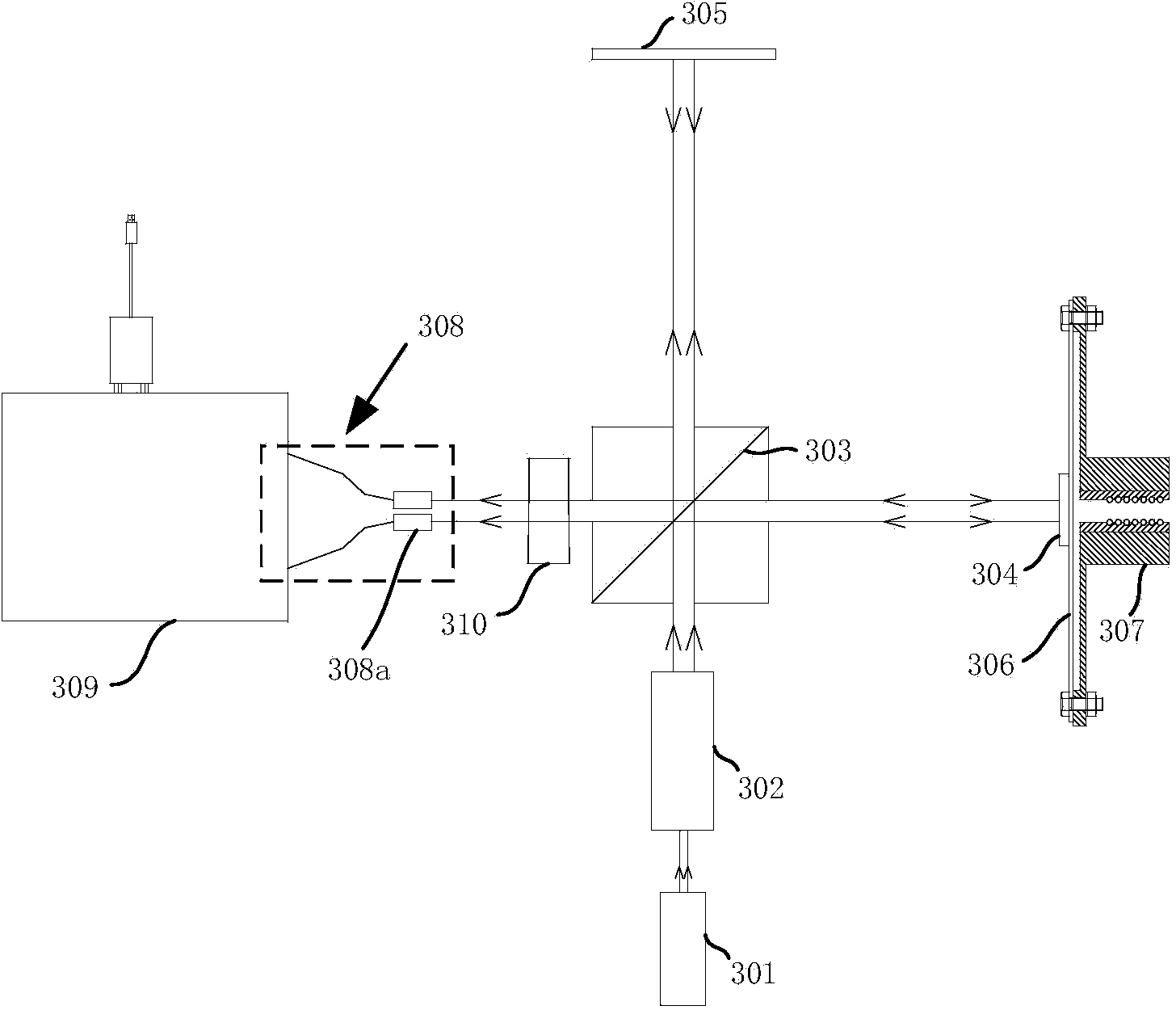

[0038] The high-precision optical micro-thrust measurement system based on the principle of double-beam interference of the present invention includes an engine suspension assembly 1, a thrust calibration assembly 2, a thrust measurement optical system 3 and a computer 4, such as figure 1 shown.

[0039] The engine suspension assembly 1 includes a suspension bolt 101 and a suspension fishing line 102, which are used to suspend the engine 5 to be measured on a fixed surface; wherein, the suspension studs 101 are fixedly mounted on the side walls at the front and rear ends of the engine 5 to be measured, respectively The suspension of the engine 5 to be measured is realized by fixing the hanging fishing line 102 to the installation surface.

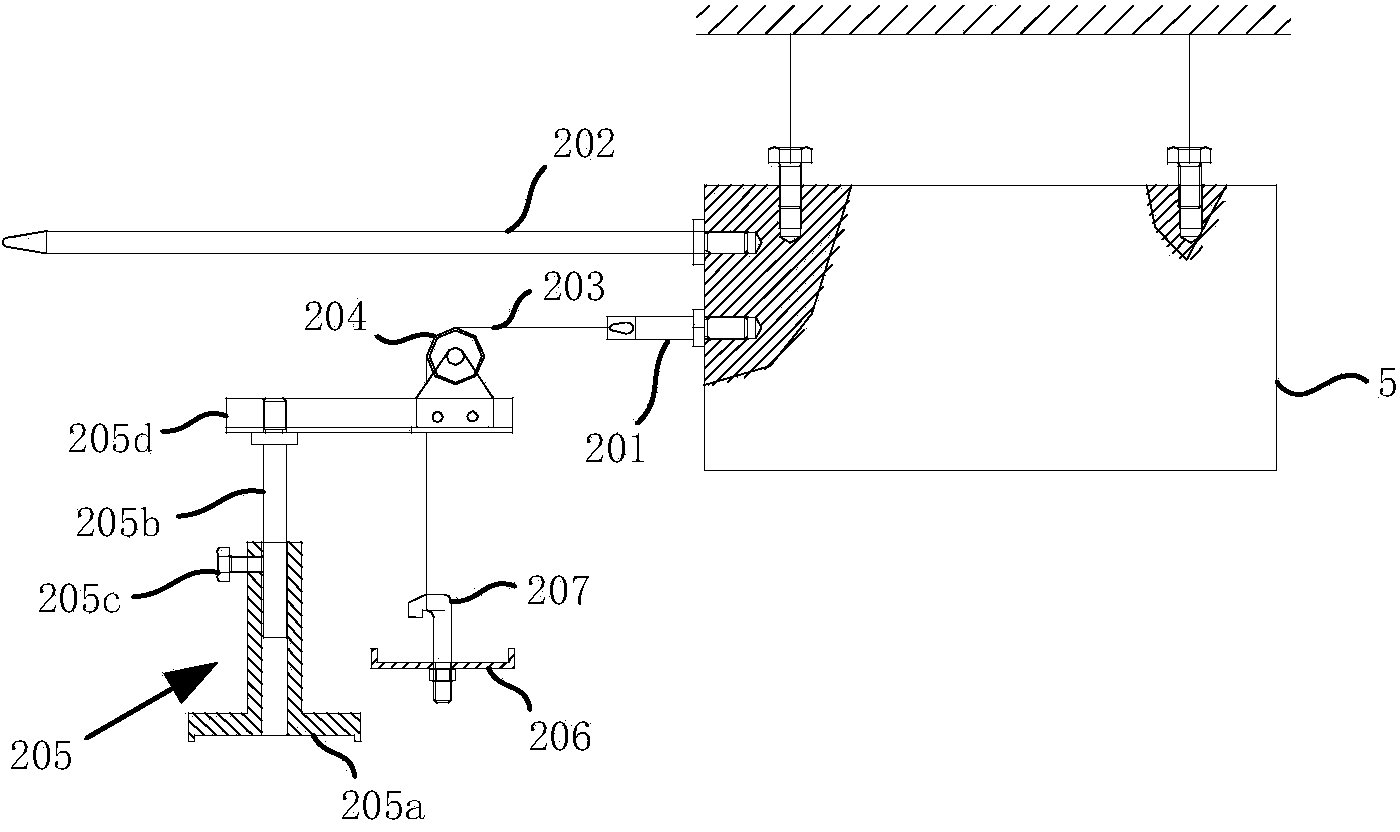

[0040] The thrust calibration assembly 2 includes a calibration center rod 201, a push rod 202, a calibration fishing line 203, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com