Self centering chuck

A self-centering chuck and self-centering technology, applied in the direction of chucks, etc., can solve the problems of increased procedures, affecting work efficiency, and low efficiency, and achieve the effects of saving chucking time, reducing chucking procedures, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

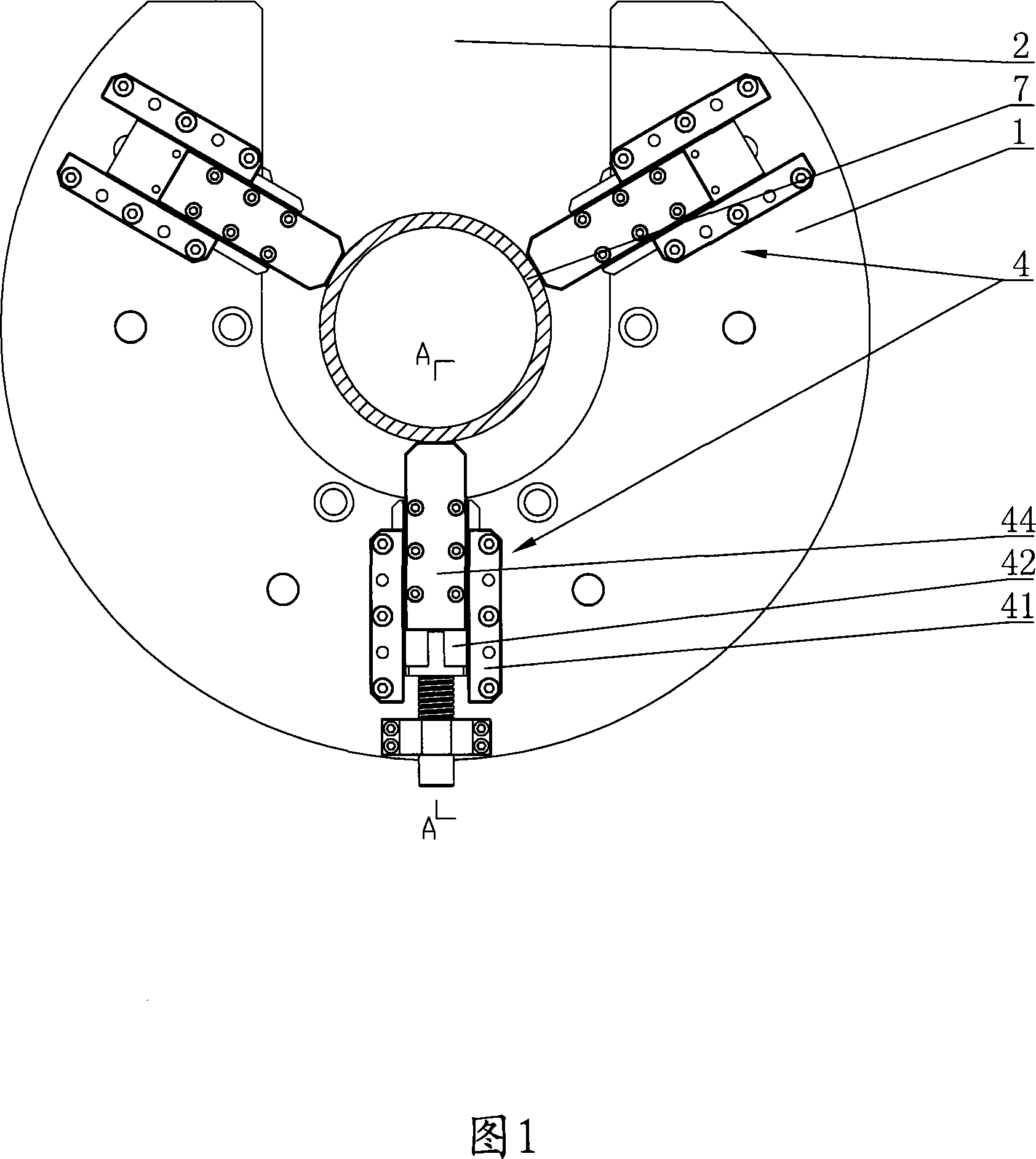

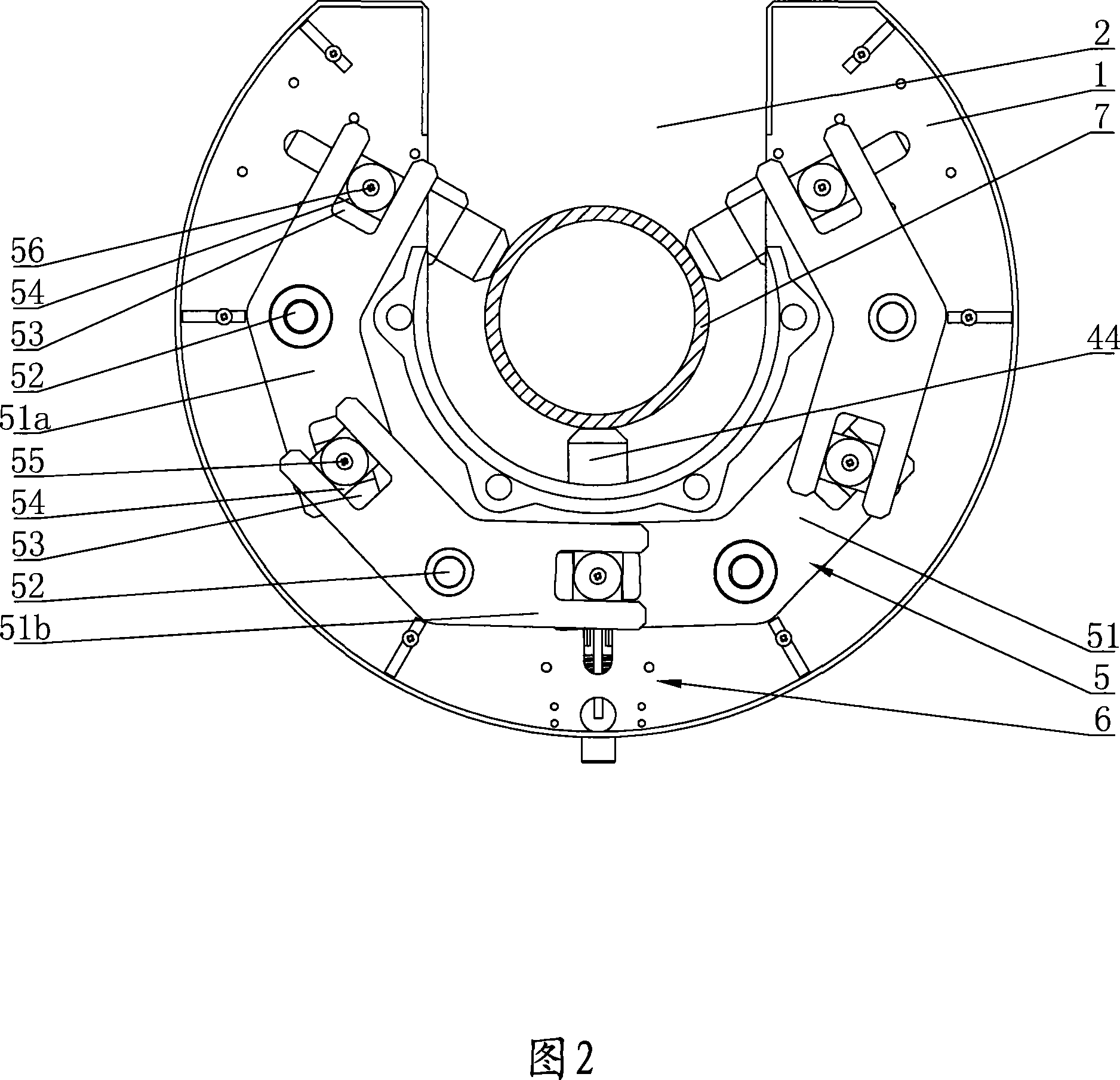

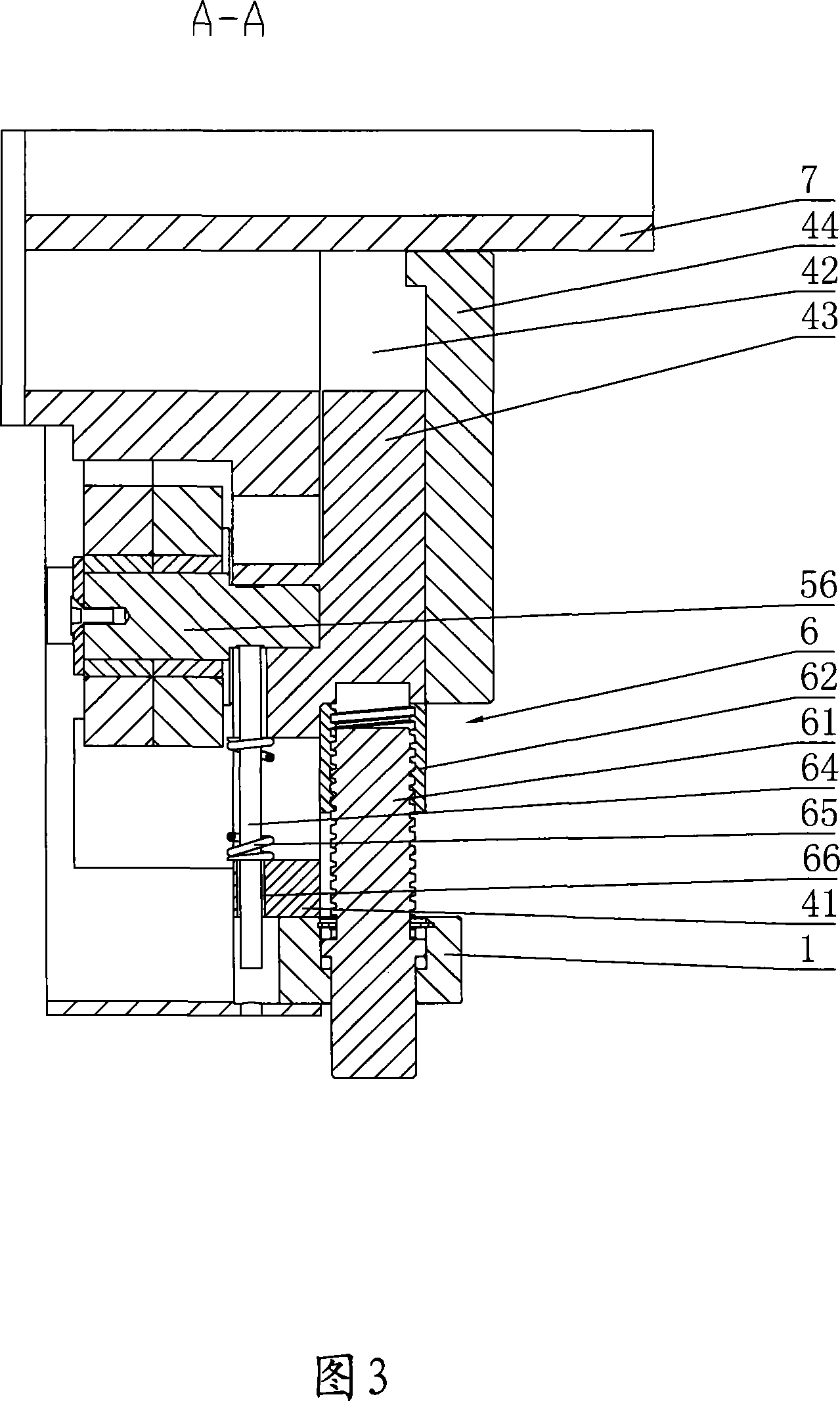

[0025] Referring to Fig. 1 , a self-centering chuck includes a chuck body 1, the chuck body 1 has a jaw mechanism 4 for clamping a workpiece 7, and is used for adjusting the jaw mechanism 4 The adjustment mechanism 6 for the state of the jaw mechanism 4 and the self-centering mechanism 5 for controlling the equidistant movement of each jaw 44 of the jaw mechanism 4 relative to the center of the chuck. In addition, the top of the chuck body 1 is provided with an opening 2 to facilitate the insertion and removal of the workpiece 7, the opening 2 runs through the thickness of the chuck body 1, and the opening 2 The size should ensure that the workpiece 7 with the largest diameter for the jaw mechanism 4 can pass through said opening 2 . Due to the setting of the opening 2, the workpiece 7 can be directly hoisted to the center of the chuck and loaded, and taken out directly from the center of the chuck, which is very convenient.

[0026] At the same time, due to the setting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com