Vacuum sublimation purifying method for high-purity arsenic and vacuum sublimation furnace thereof

A purification method and sublimation furnace technology, applied in the field of non-ferrous metal smelting and purification, can solve the problems of unreasonable longitudinal temperature distribution, loss of purification effect, large amount of arsenic vapor, etc., and achieve good separation and condensation effect of impurities, reasonable temperature gradient distribution, and high temperature The effect of uniform field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

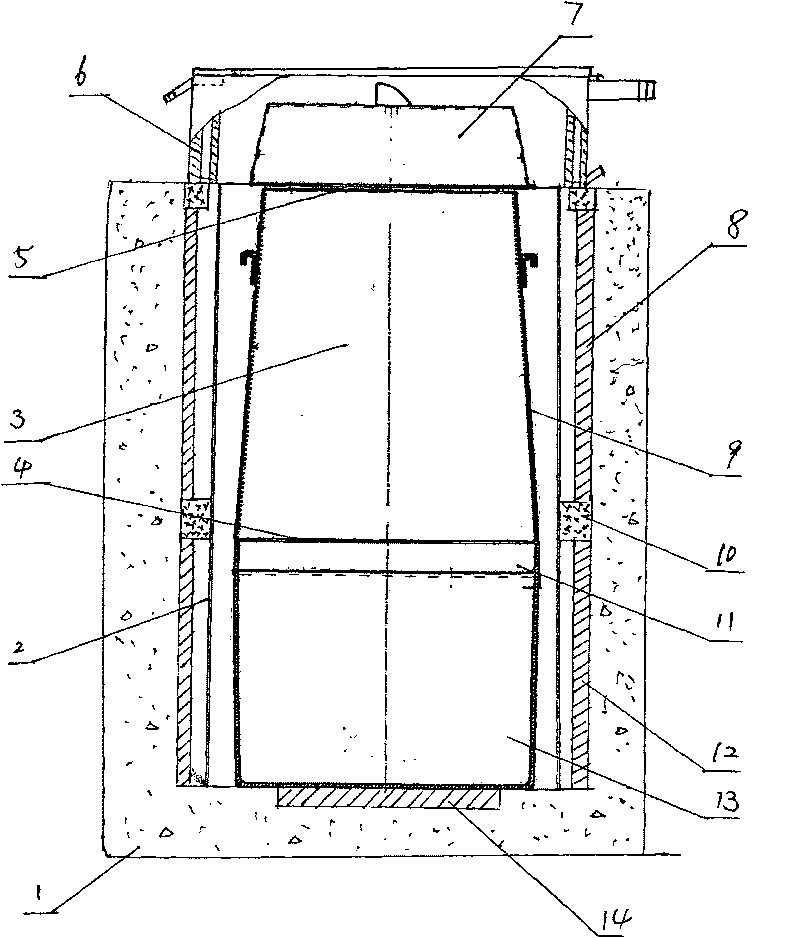

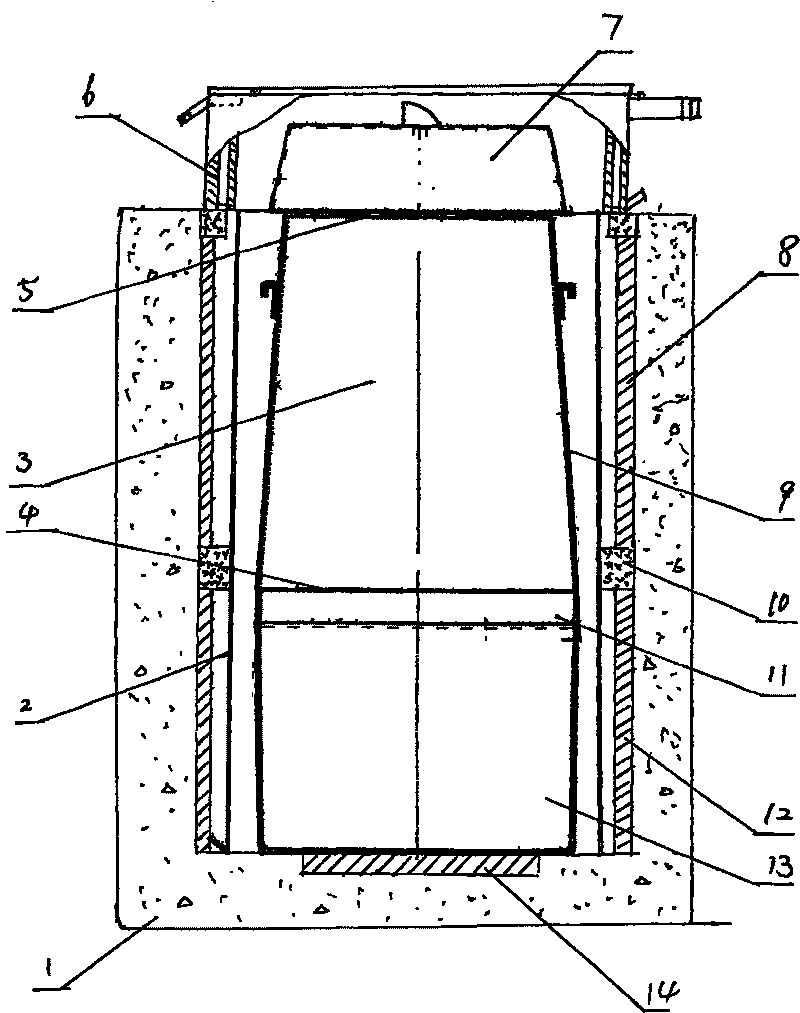

[0017] A vacuum sublimation purification method for high-purity arsenic, using a vacuum sublimation furnace for sublimation purification,

[0018] Three independent temperature control areas are used in the vacuum sublimation furnace, namely the volatilization temperature control area located in the lower part of the device, the arsenic product temperature control area located in the middle of the device and the impurity collection temperature control area located in the upper part of the device.

[0019] An independent heating device is installed in the volatilization temperature control area and the arsenic product temperature control area,

[0020] The temperature control method of the volatile area is as follows: 1. Raise the temperature to 480°C to 520°C within 110 to 130 minutes, and keep the temperature constant for 50 to 70 minutes; 2. Then raise the temperature to 530°C within 25 to 35 minutes ~580℃, constant temperature for 10~12 hours;

[0021] The temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com