Permanent magnetic gravitation inertia conversion engine

A technology of engines and permanent magnet rotors, applied in generators/motors, electrical components, etc., can solve problems such as inability to continuously generate energy, depletion of petroleum resources, and pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

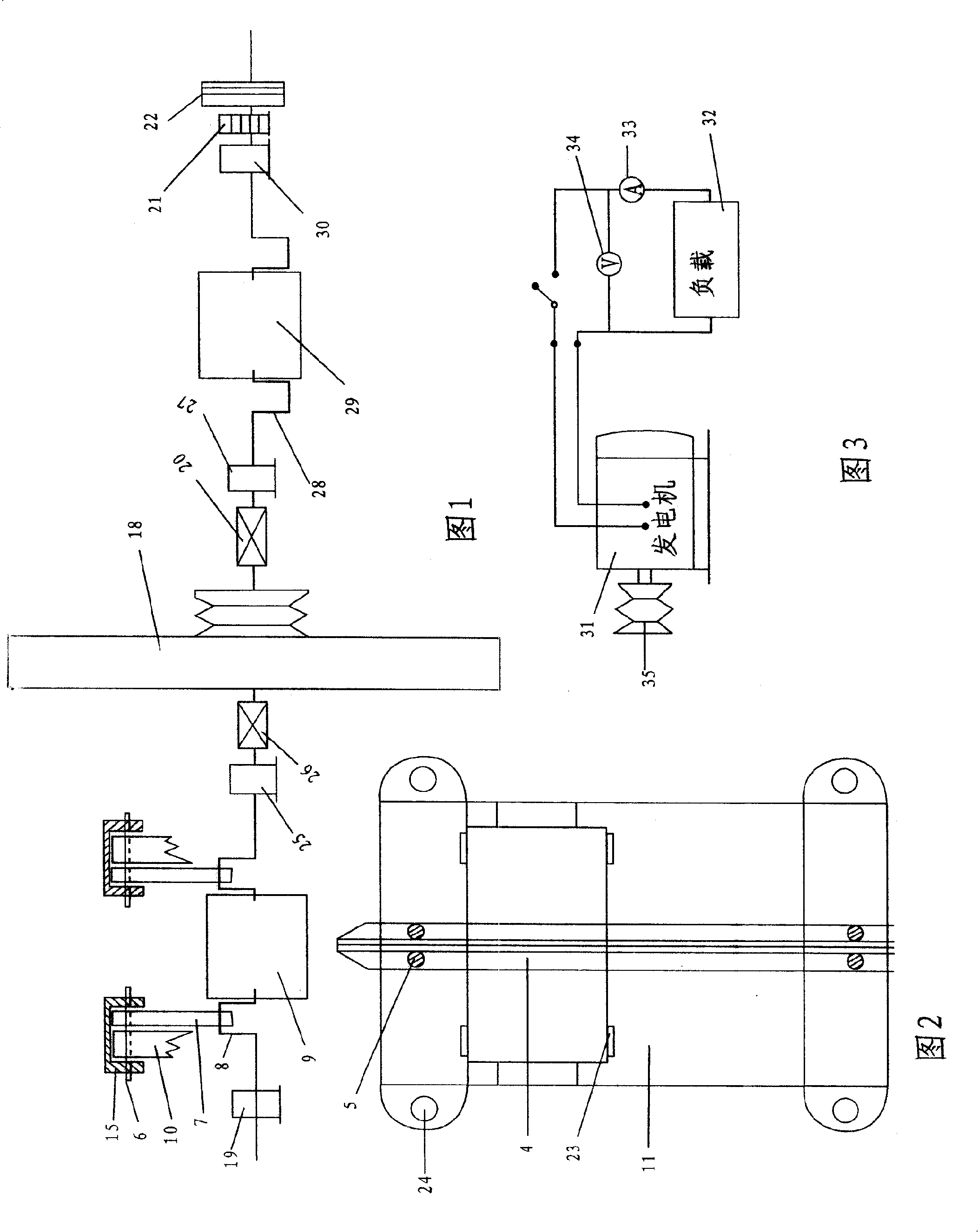

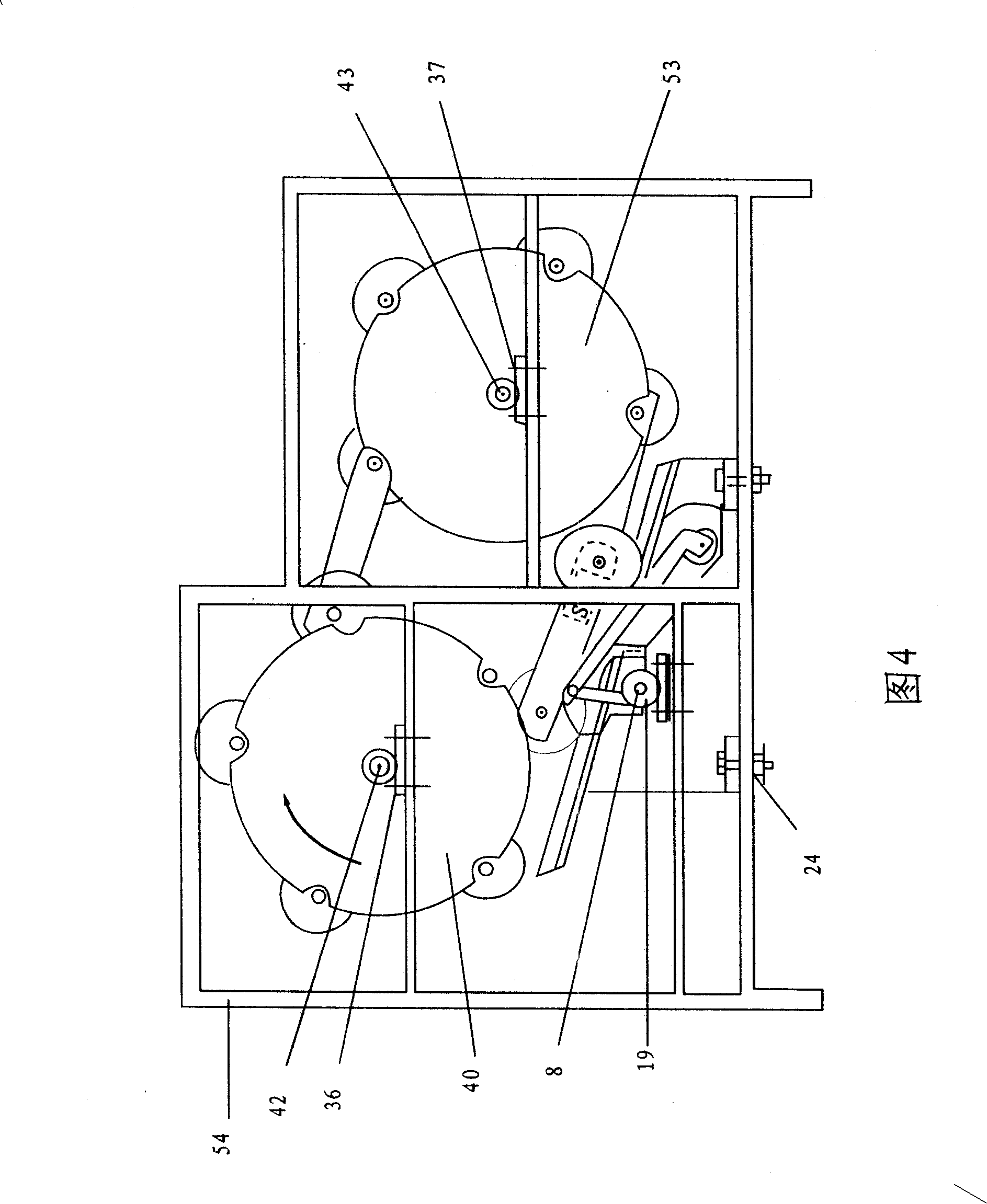

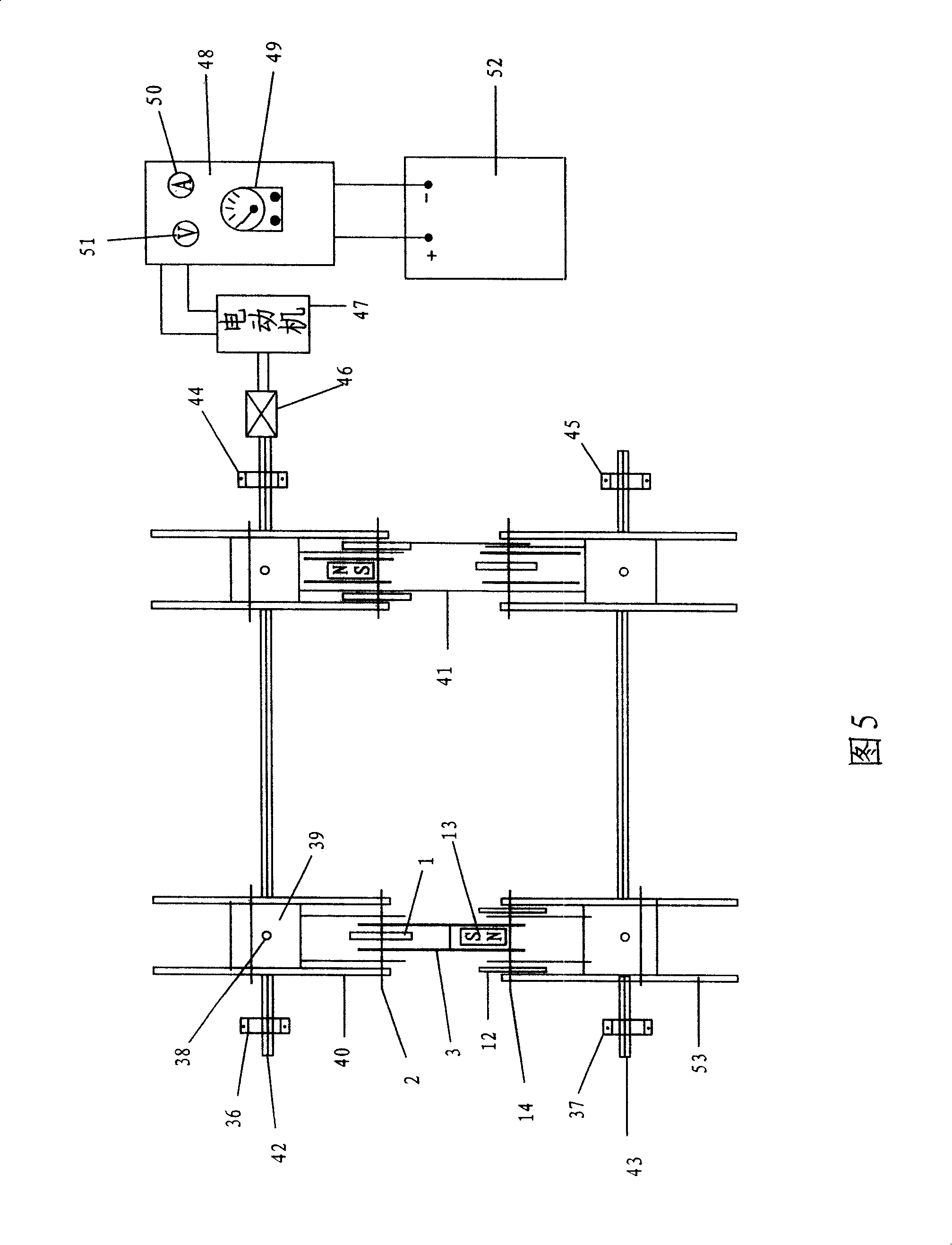

[0081] The basic working principle of the present invention will be further described in detail below in conjunction with the drawings and the present embodiment: What is described in claim 1 is a rotor crankshaft mechanism with symmetrical crankshaft directions of 180 degrees each other, with an inertia wheel in the middle. , They are fixedly connected together by a coupling. Four connecting wheels are supported by two shafts, and two permanent magnet chains are installed on the sprocket to cooperate with the rotor crankshaft system. The magnetic pole direction of the permanent magnet rotor is parallel to the two circular planes of the cylindrical rotor. Picture 9

[0082] The direction of the poles of the rectangular magnets on the flux linkage cart is straight and long. Picture 10

[0083] The crankshaft connecting rod, the slider, the movable track and the permanent magnet link change the force direction of the permanent magnet on the magnet link car, making it consistent wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap