Waterproofing mechanism for emulsion pump

An anti-water, lotion pump technology, applied in the field of lotion pumps, can solve the problems of liquid product pollution, accumulation of liquid suction inside the container, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

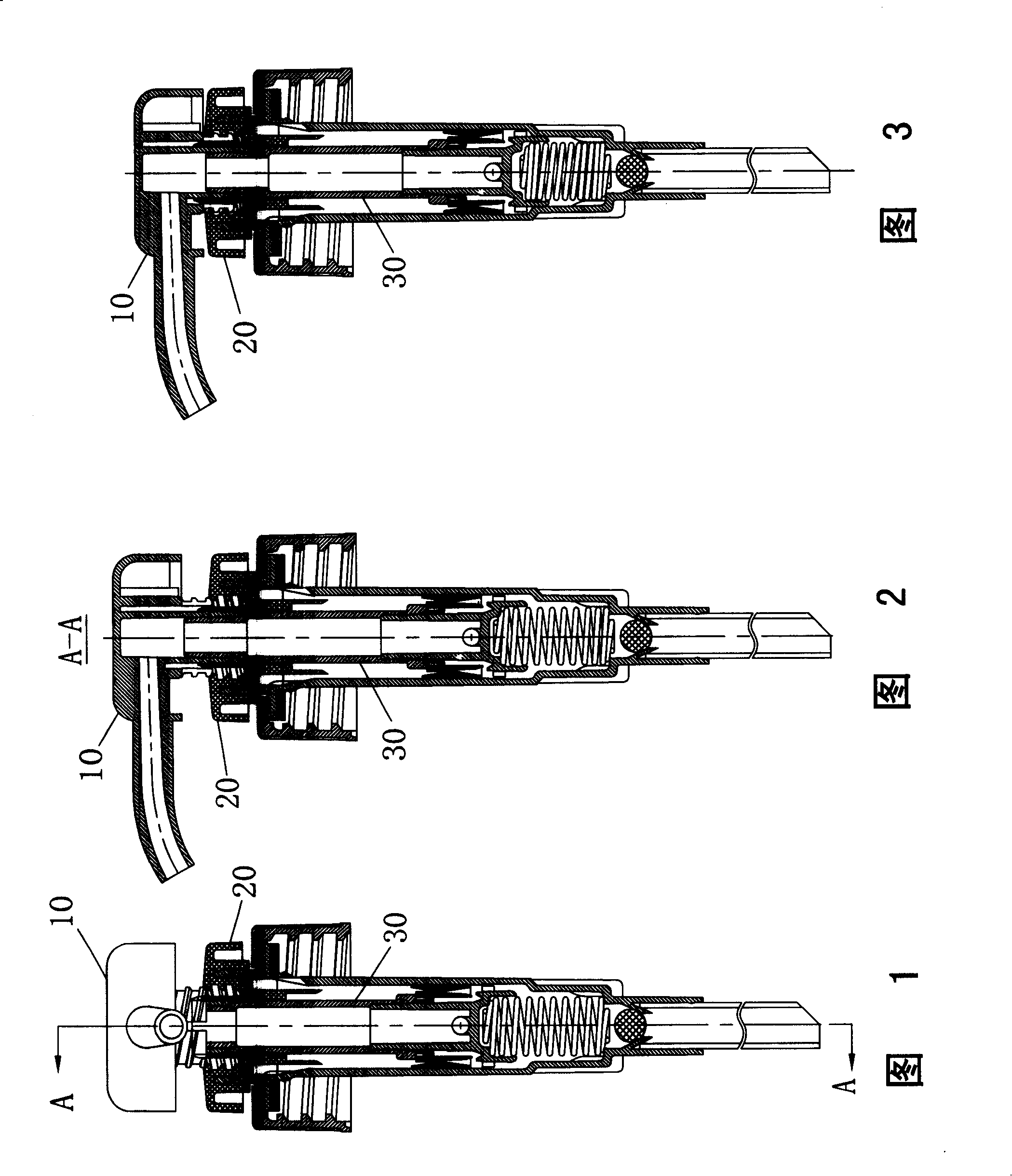

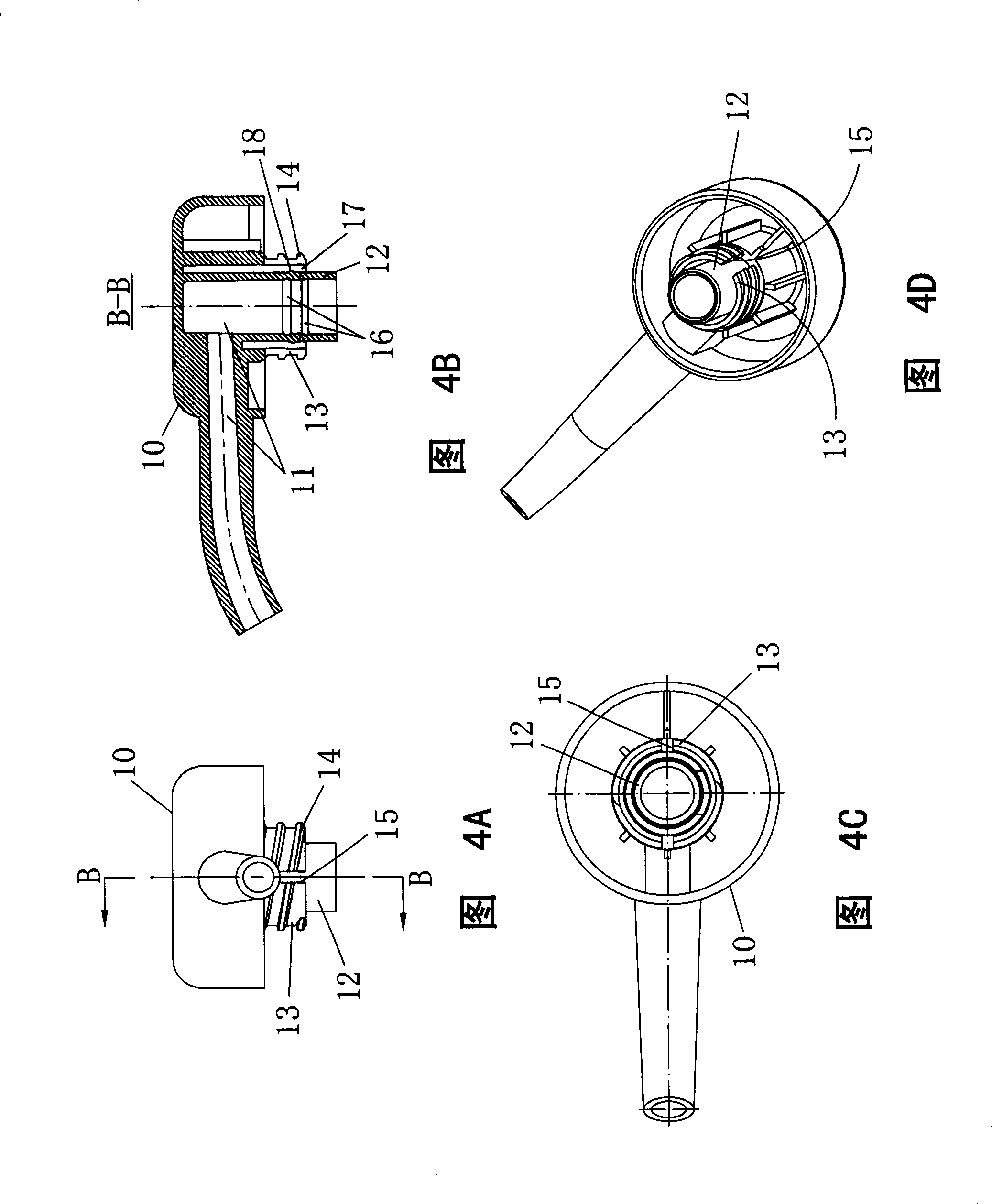

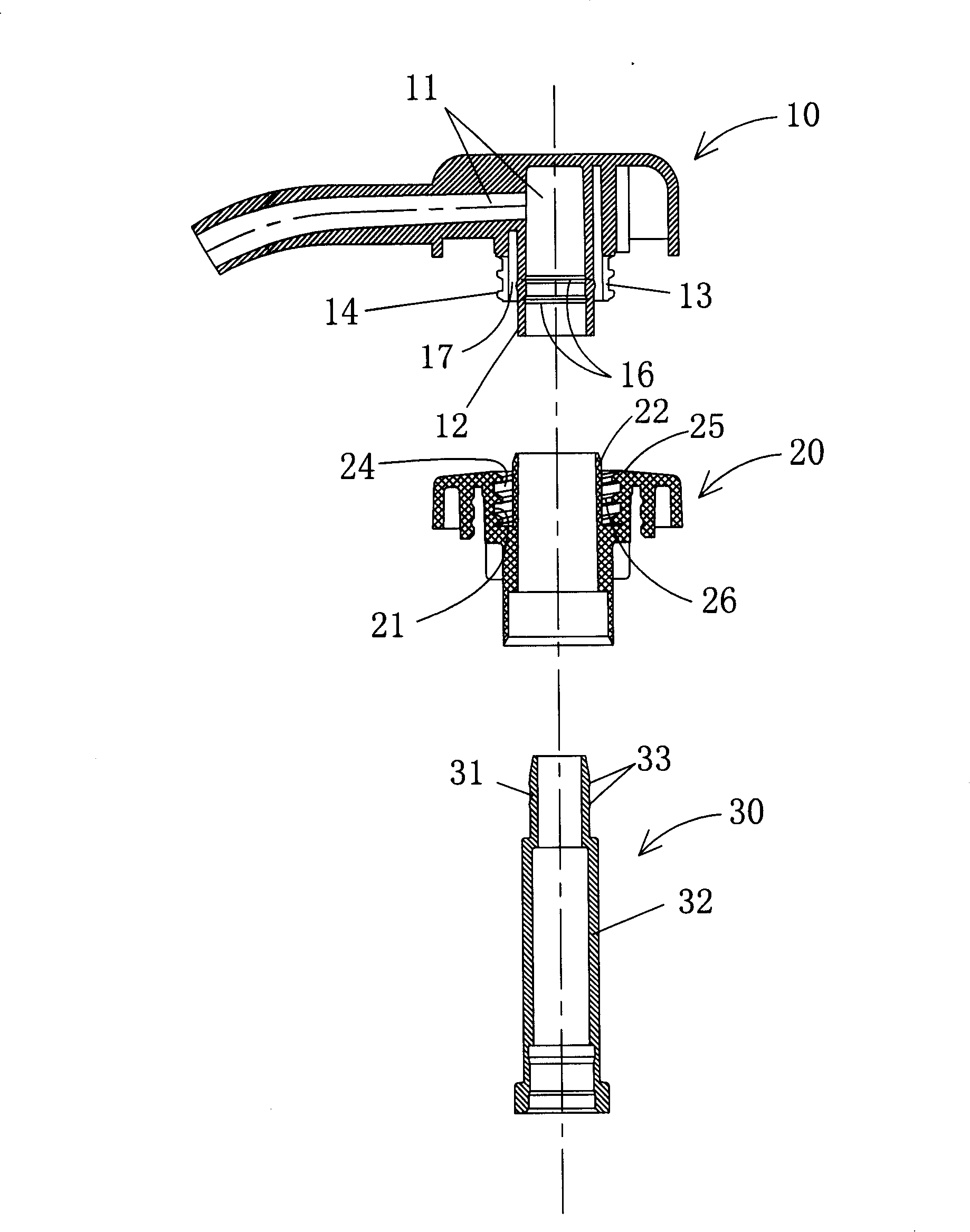

[0021] 1-3, the lotion pump anti-water mechanism of the present invention is combined in a traditional type of lotion pump, and the lotion pump is used to be installed on the opening of a container (not shown) to process the product in the container Pump pressure distribution. The anti-water mechanism of the lotion pump generally includes a pressure head 10, a connecting conduit 30 fixedly connected to the lower part of the pressure head 10, and a cylinder head 20 with a central through hole for the connecting conduit 30 to pass through. Above-mentioned pressure head 10, connecting conduit 30 and cylinder head 20 and some other components (as shown in the figure, their structure and their cooperation with the components of the present invention belong to the prior art) constitute the emulsion pump, but because the emulsion of the present invention The anti-ingress mechanism of the pump basically only involves these three components, so this article does not describe the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com