Electric cooking appliance

A technology of electric cooking utensils and connecting seats, which is applied in the direction of electric heating devices, electrical components, household appliances, etc., can solve the problems of breaking, troublesome cleaning of the upper cover, poor contact between connecting wires and circuits, etc., and achieves a simple and reasonable structure and a high degree of safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

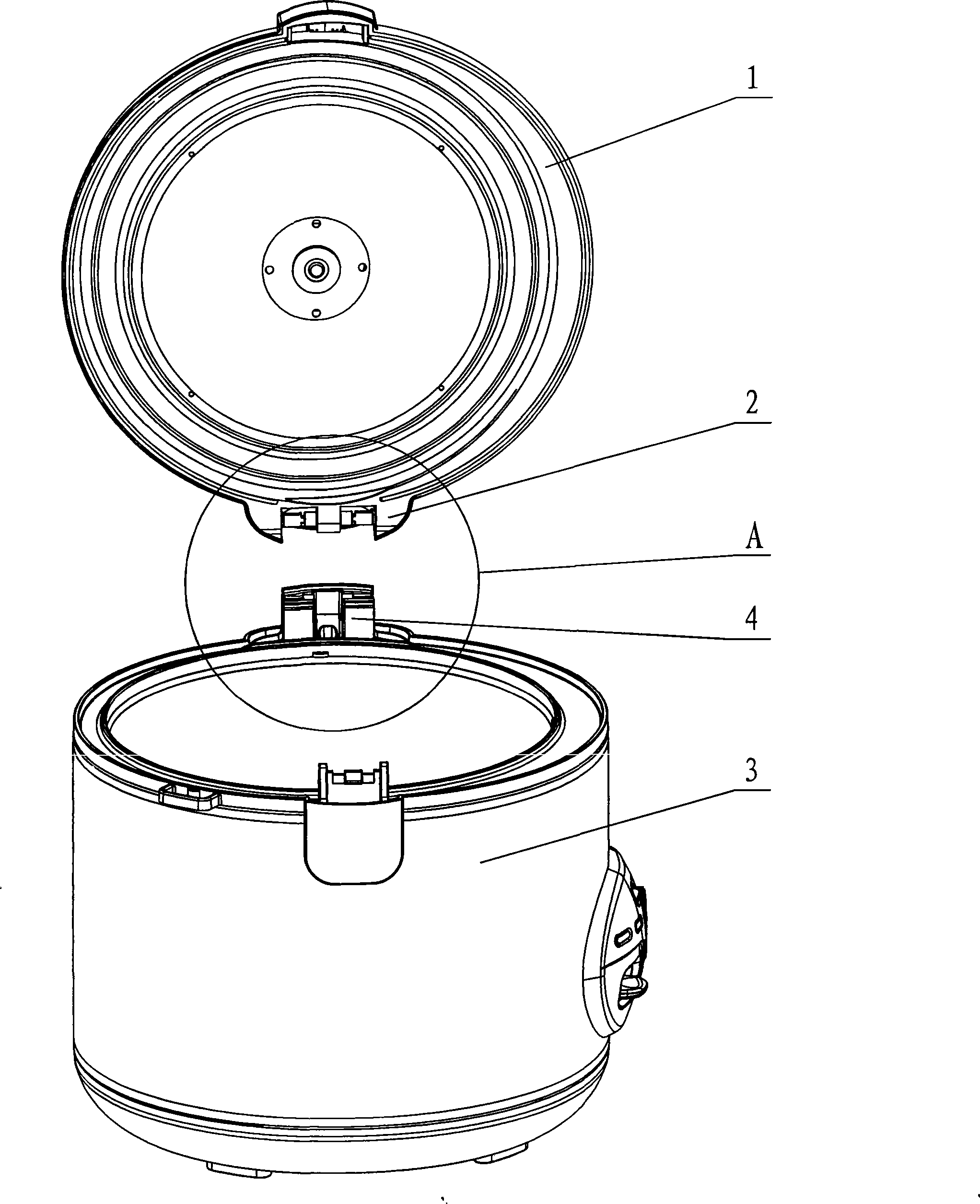

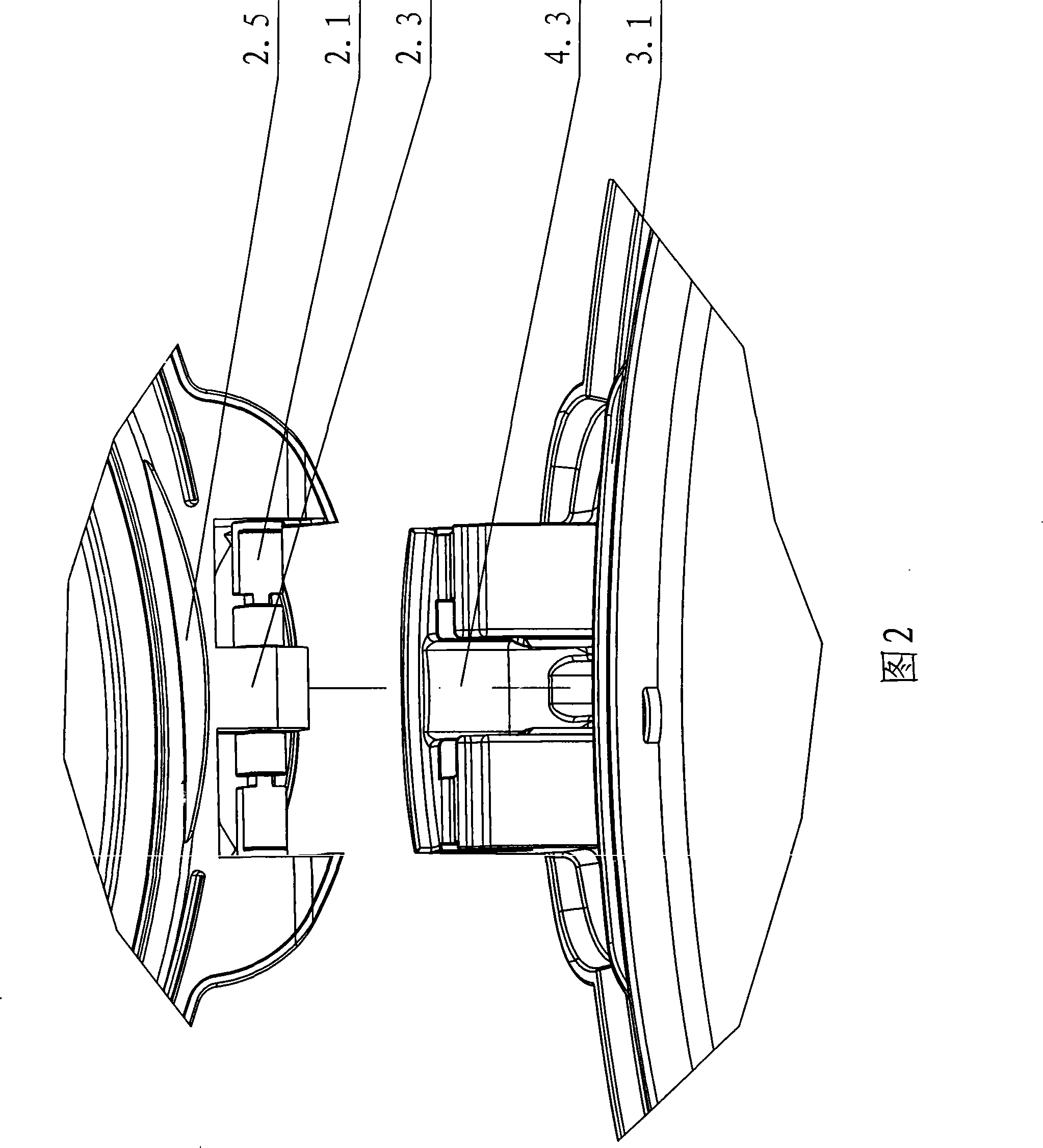

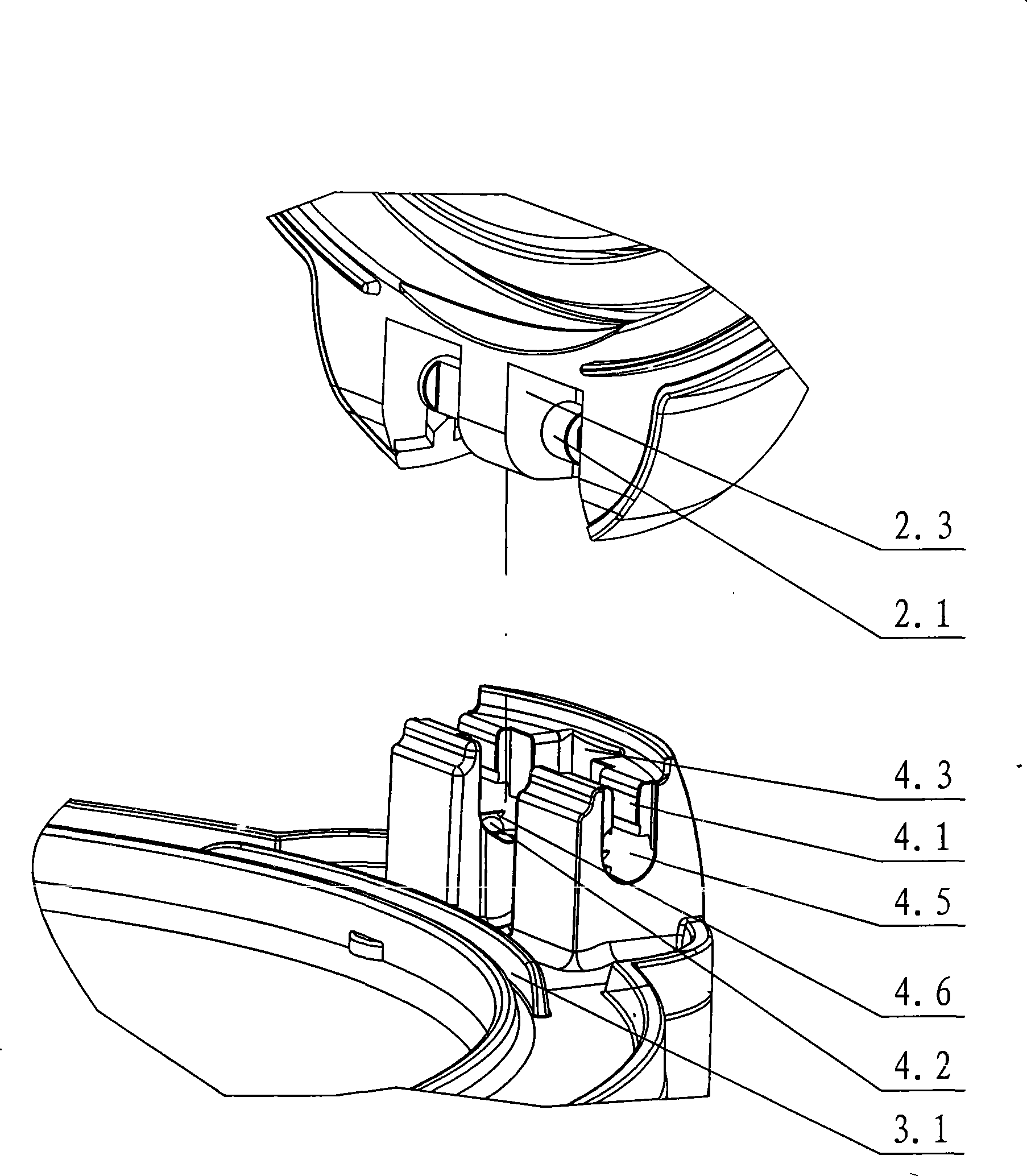

[0025] see figure 1 - Fig. 6, the electric cooker includes an upper cover 1 pivotally arranged on the pot body 3, the upper cover is provided with an upper connecting seat 2, the pot body is provided with a lower connecting seat 4, and the upper connecting seat 2 is inserted into the lower connecting seat 4 There are grooves on the upper and upper connecting seats, and a boss 2.3 is arranged in the center of the groove. The two conductive shafts 2.1 and the upper connecting terminals 2.2 for the live wire and the neutral wire are respectively arranged on the left and right sides of the boss, and the lower connecting seat 4 corresponds to the boss. The table is provided with a turn slot 4.3, and two assembly grooves 4.5 are respectively arranged on both sides of the turn slot. A conductive rotating shaft 2.1 with an upper connection terminal 2.2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com