Method for preparing modified polymethyl methyl acrylate material and the material

A polymethyl methacrylate, modified technology, applied in the direction of coating, can solve the problems of small surface hardness, poor heat resistance, low temperature of PMMA, and achieve good hydrophilic durability and improve wear resistance. Effect

Inactive Publication Date: 2010-08-11

FUZHOU UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use temperature of PMMA is low (65°C), poor heat resistance (thermal decomposition temperature ≤ 200°C), low surface hardness, and it is easily affected by ultraviolet rays in the sun and aging during use, which limits its application range.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

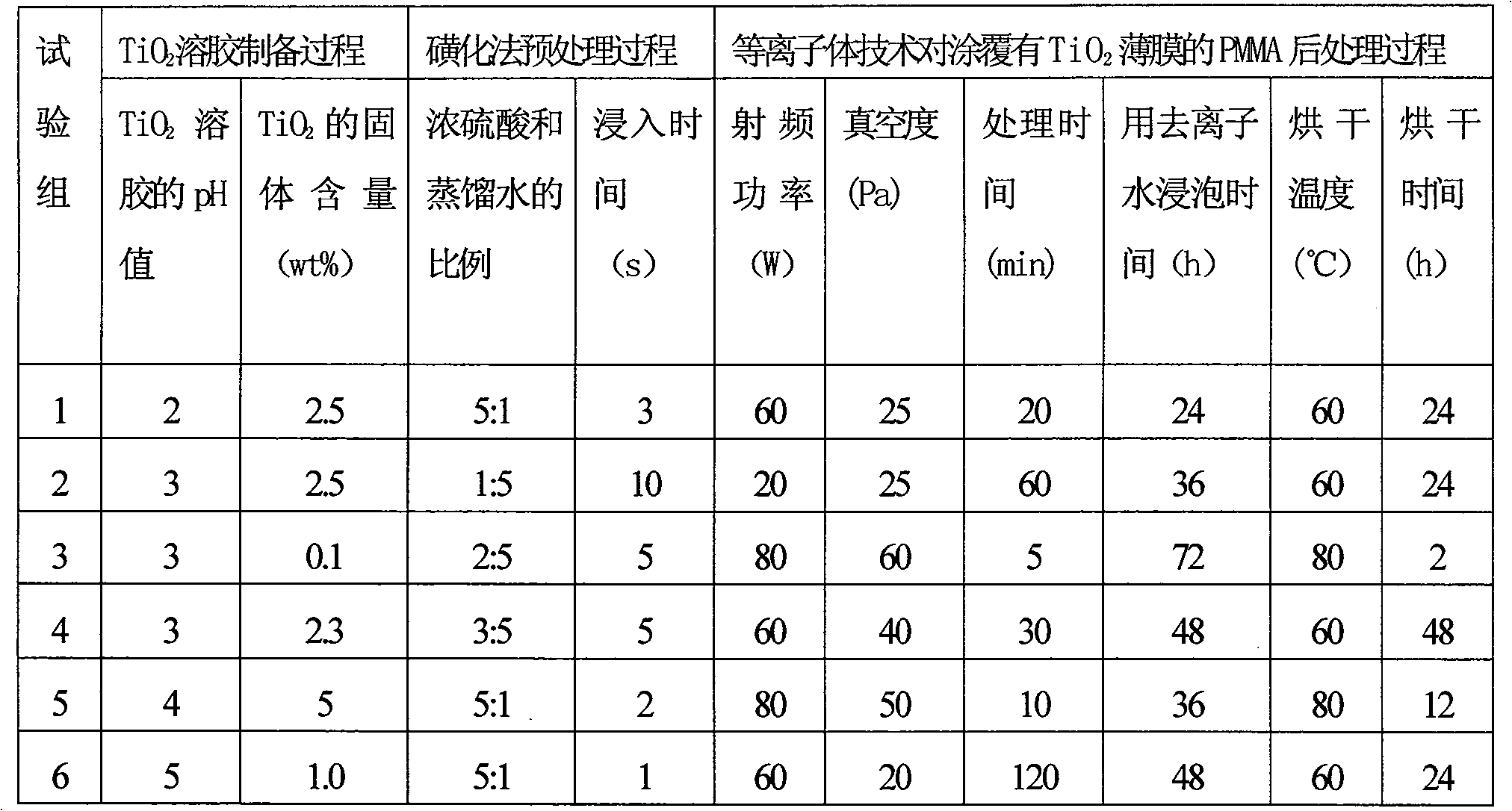

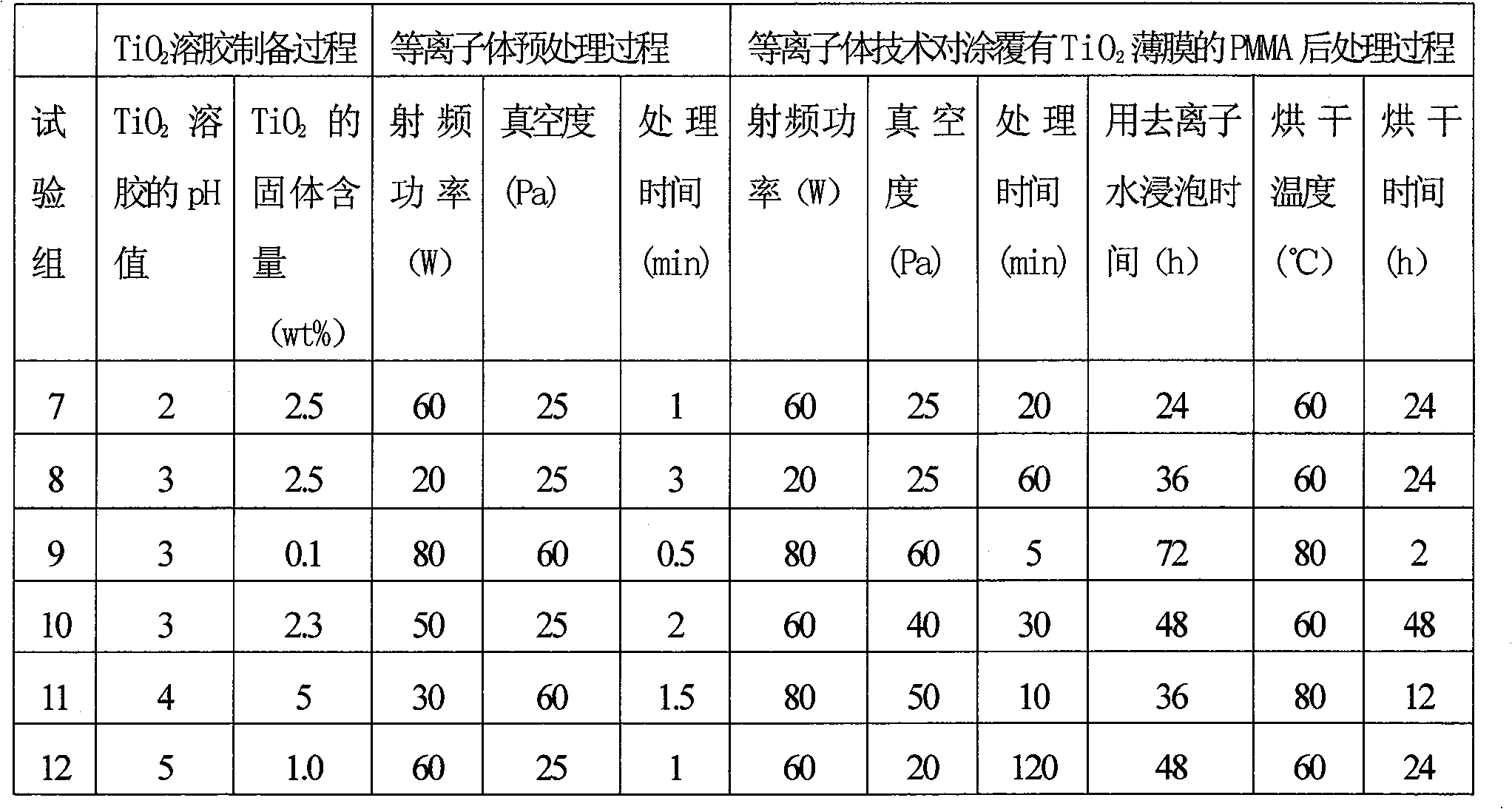

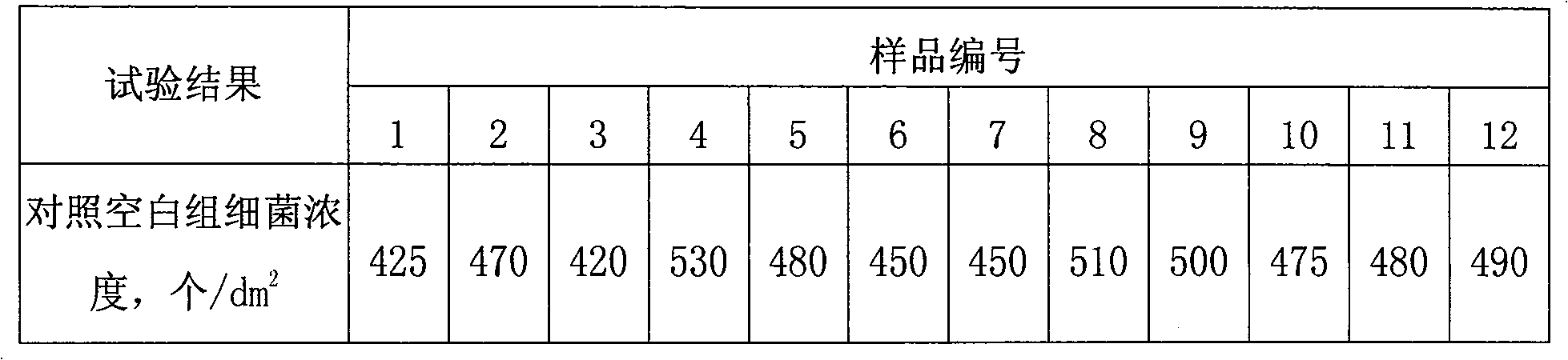

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a preparation process of modified polymethyl methyl acrylate material, which comprises firstly washing PMMA in NaOH and acetone solution in turn for 2-3 times through an ultrasonic cleaner, removing grease and dirt on the surface, drying with a vacuum drying box for backup, and then directly depositing titanium dioxide precursor solution on the surface of polymethyl methyl acrylate material through the bionic film-forming technology. The technology aims to prepare self-cleaning polymethyl methyl acrylate material which has anti-aging, wear resistance surface and anti-fog and sterilization through combining with the characteristics of polymethyl methyl acrylate and titanium dioxide, and utilizing the titanium dioxide characteristics of wear resistance, absorbing ultraviolet light, and sterilization and antibiosis and dirt-preventing and self-cleaning on the surface under the irradiation of lights, thereby expanding application ranges.

Description

This invention patent application is a divisional application with the filing date of April 14, 2006, application number 200610018801.6, name: modified polymethyl methacrylate material and its preparation method. technical field The invention relates to a modified polymethyl methacrylate (PMMA) material and a preparation method thereof, specifically coating a layer of titanium dioxide nano-film on the surface of PMMA to improve certain properties and expand its application field technology . Background technique Polymethyl methacrylate (PMMA) is a very important kind of transparent polymer materials, commonly known as plexiglass. It has many excellent properties, such as good chemical stability, balanced physical and mechanical properties, good processing performance, weather resistance, electrical insulation, excellent optical properties, light transmittance is more than 10% higher than ordinary inorganic glass, and light weight Toughness, etc., so it is widely used in m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J7/06C08L33/12

Inventor 付贤智翁景宁苏文悦王绪绪刘平戴文新王柿超

Owner FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com