Modified polymethyl methacrylate materials and process for preparing same

A polymethyl methacrylate, modification technology, applied in the direction of coating, can solve the problems of small surface hardness, poor heat resistance, low temperature of PMMA, and achieve the effect of good hydrophilic durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

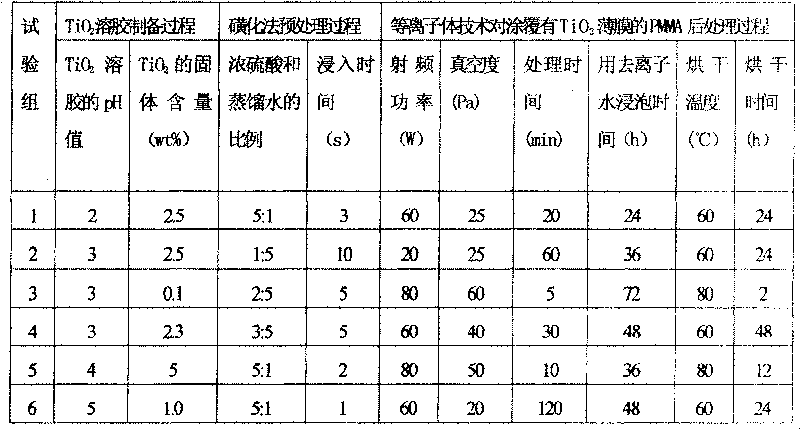

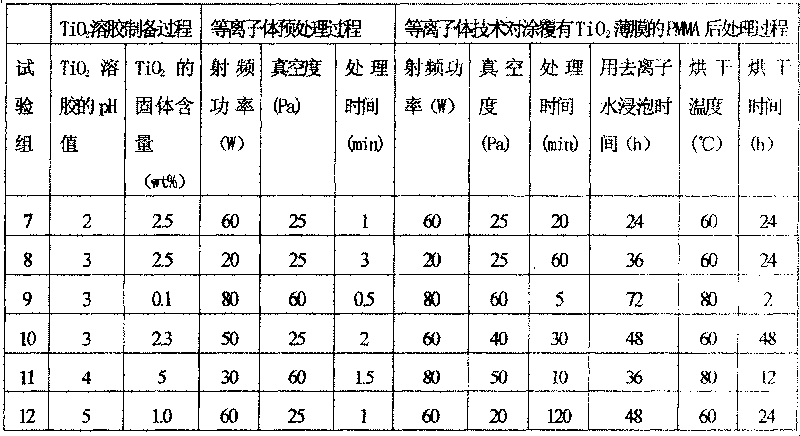

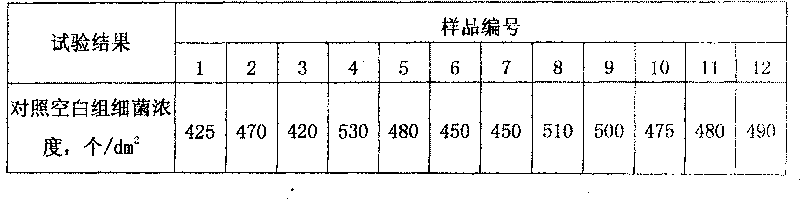

Examples

preparation example Construction

[0014] 1. Preparation and chemical modification of titanium dioxide sol

[0015] (1) Preparation of titanium dioxide sol: Hydrolyze titanium alkoxide (such as tetraisopropyl titanate, or tetrabutyl titanate or others) under the condition of acidic pH2 The solid content is 0.1~5.0wt% (weight volume percentage).

[0016] 2. Pretreatment of the surface of polymethyl methacrylate material

[0017] There are two methods for pretreatment of the surface of polymethyl methacrylate materials:

[0018] (1) Sulfonation method: Mix concentrated sulfuric acid and distilled water at a volume ratio of 5:1 to 1:1, then cool down, immerse the polymethyl methacrylate material in the solution for 1s to 10s, then take it out quickly, and wash it with distilled water The residual liquid on the surface should be dried for later use.

[0019] (2) Plasma treatment: put the polymethyl methacrylate material into a radio frequency plasma generator, and use O with a purity of 99.999% 2 RF plasma, the ...

Embodiment 1

[0024] Embodiment 1: the preparation of titania sol

[0025] Add 1.1 milliliters of concentrated nitric acid (68%) into 150 milliliters of deionized water to make a uniform solution, slowly drop 12.5 milliliters of tetraisopropyl titanate into the acidic aqueous solution under vigorous stirring, and hydrolyze the obtained suspension containing white precipitate Stirring was continued at 40 °C until the white precipitate dissolved to form a homogeneous transparent sol. Put the sol into a dialysis membrane bag and perform dialysis treatment with 2 liters of deionized water, and change the water every 12 hours until the final pH value of the dialysis water is 3.0. The sol was taken out from the dialysis bag to prepare a titanium dioxide sol with a concentration of about 2.5% (percentage by weight and volume).

Embodiment 2

[0026] Embodiment 2: PMMA material surface TiO 2 Preparation of base nanofilms

[0027] First pretreat the PMMA material according to the sulfonation method, that is, first mix the concentrated sulfuric acid and distilled water in a volume ratio of 2:1 and then cool it, then immerse the PMMA in the solution for 2 seconds, then take it out, and wash the residual liquid on the surface with distilled water ,dry.

[0028] The above-mentioned pretreated PMMA is put into a screen, and the screen is put into the TiO prepared in Example 1. 2 In the sol, pull it out at a speed of 1cm / min, place it in a radio frequency plasma generator after drying, and use O 2 (O 2 Purity is 99.999%) radio frequency plasma for surface post-treatment, radio frequency power is 60W, vacuum degree is 25Pa, and treatment time is 20min. After the plasma treatment, the sample was soaked in deionized water for 36h, and then dried at 80°C or lower for 4h to obtain a TiO-coated 2 Plexiglass PMMA for photoca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com