Well-washing sand prevention integrated technique tubular pile

A technology for process strings and sand control screens, applied in the direction of flushing boreholes, drill pipes, casings, etc., can solve the problems of complicated construction operations, sand plugging, and increased operating costs, and achieve optimal design of the release mechanism and ensure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

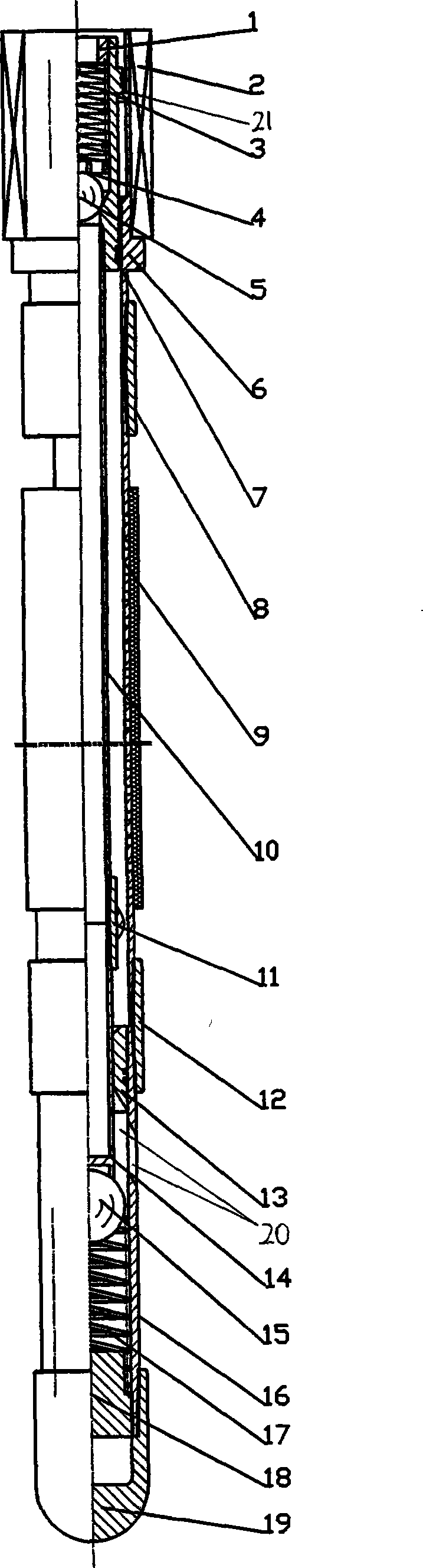

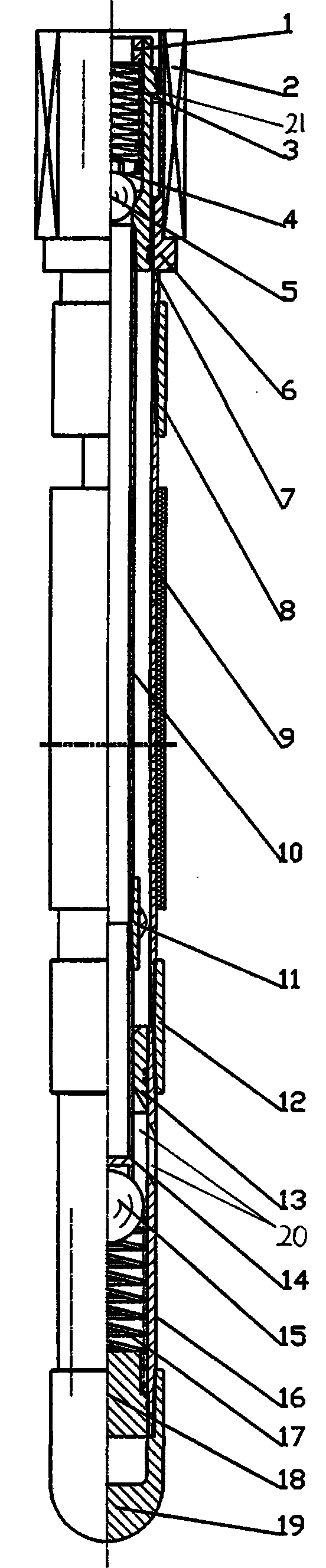

[0011] Referring to the accompanying drawings, a well cleaning and sand control integrated process pipe string includes an upper ball valve and a suspension mechanism, a lower joint, a coupling, a sand control screen, a flushing pipe, a centralizer, a connecting sleeve, a sealing body, a sealing plug, and a well cleaning valve and plug, the upper ball valve includes the valve body 7 and the upper valve ball 5 installed in it, the ball plate with holes 4, the upper spring 3 and the plug 1, the well flushing valve includes the well flushing valve body 16 and the lower spring installed in it 17. Spring seat 18 and lower valve ball 15, upper valve ball 5 and suspension mechanism 2 lower outer and lower joint 6, collar 8, sand control screen 9, connecting sleeve 12, well flushing valve body 16 and plug 19 connected with each other, the inside is connected with the flushing pipe 10, the centralizer 11 and the sealing plug 14 in sequence, the sealing body 13 is installed between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com