Method for thermal producing ultrathick oil by cyclic steam stimulation and special apparatus thereof

A special device and ultra-heavy oil technology, applied in the direction of isolation device, production fluid, earthwork drilling and production, etc., can solve the problems of casing damage, heat loss of wellbore without protection casing, long operation time, etc., to avoid heat loss Stress concentration, good heat insulation effect, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

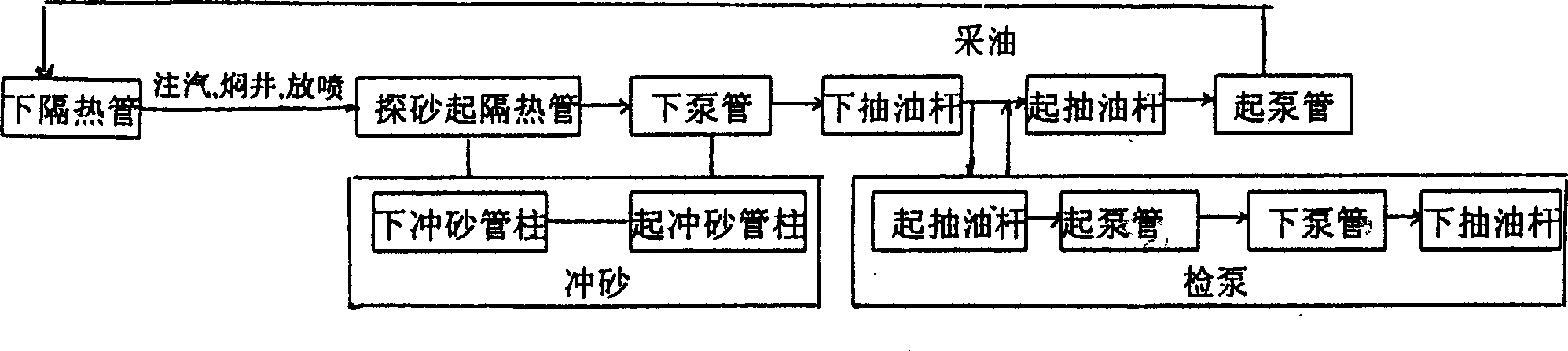

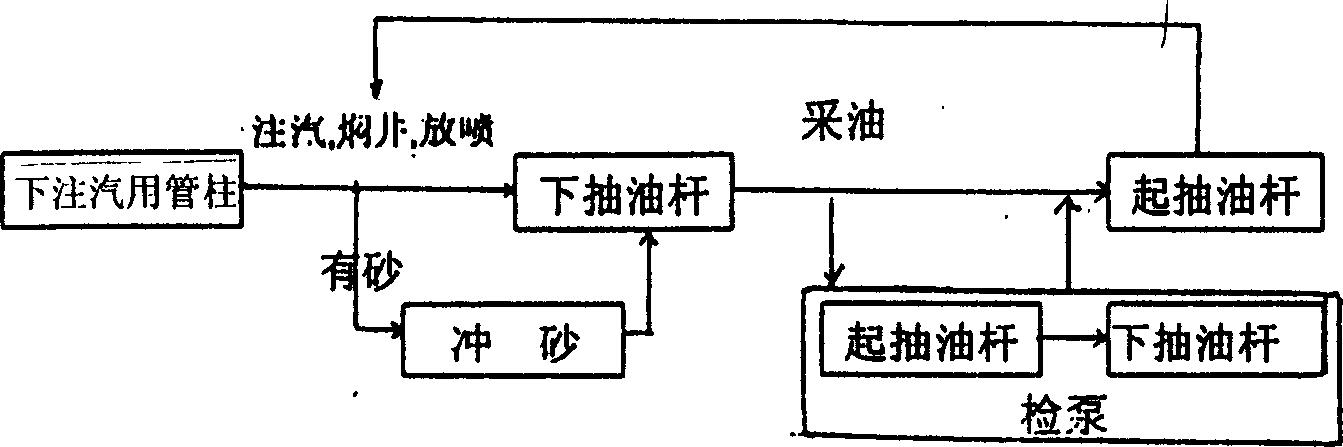

[0030] Such as figure 2 As shown, the working method of the present invention operates according to the following steps: 1) Lower the pipe string for steam injection; 2) Fill the annular cavity of the casing and the heat preservation tubing with high-pressure nitrogen, and perform steam injection according to the steam injection quantity, and the steam injection is completed Simmer the well and blow out; 3) Lower the sucker rod with sand control screen and rod pump, and then lower the cable in the hollow sucker rod to heat the oil; 4) Lift the sucker rod and inject steam after the end of oil production. Go back to step 2);

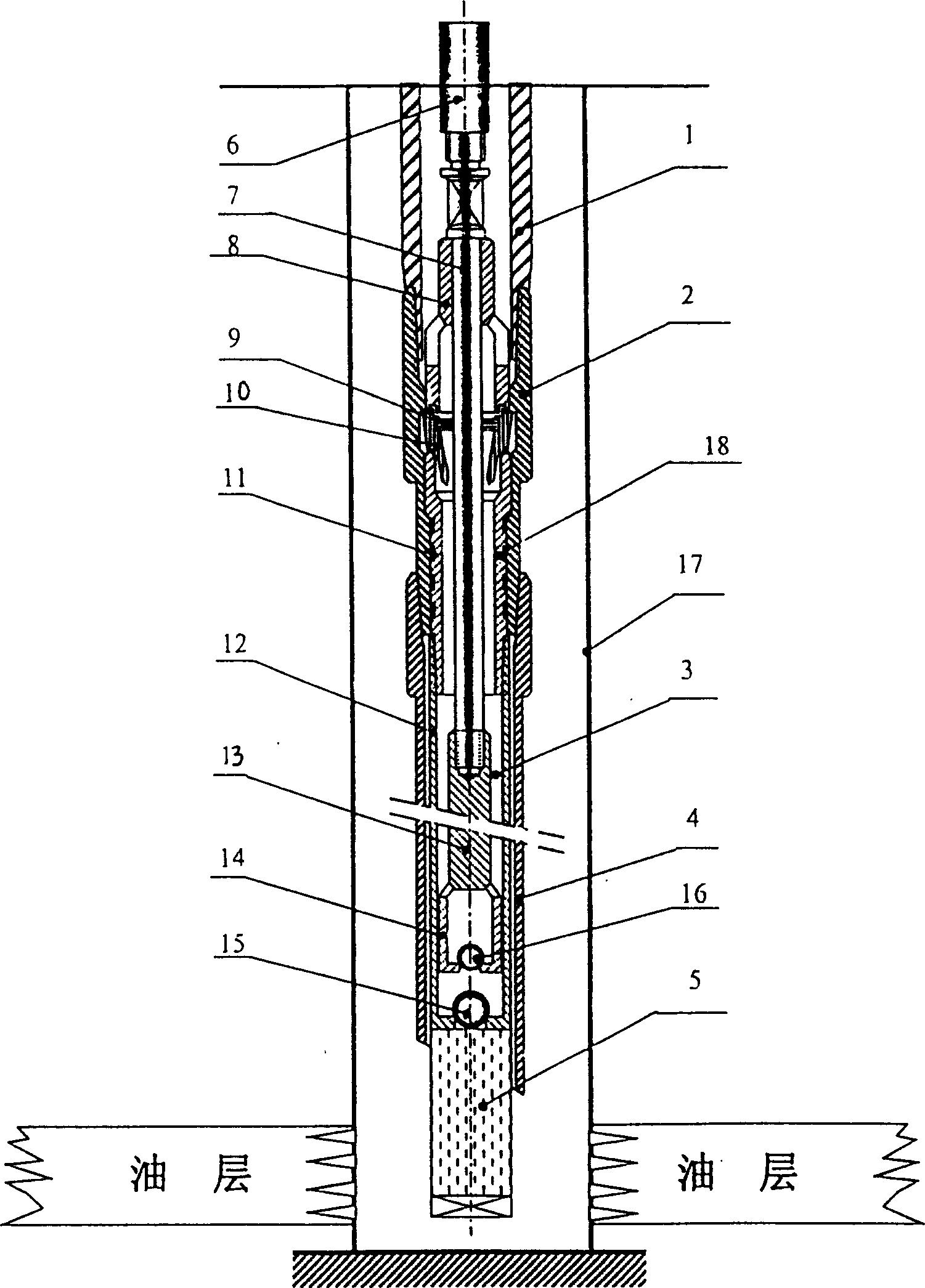

[0031] Such as image 3 As shown, the special device for the method of the present invention is placed in the casing 17, and the heat preservation tubing and the sucker rod constitute an integrated pipe string that integrates steam injection, oil production, heat preservation, sand washing and sand control. The heat preservation tubing 1 has a two-layer struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com