Compressed packer based double-sliding-sleeve type set locking mechanism

A technology of compression packer and sliding sleeve, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., and can solve problems such as resistance in drilling, rubber cylinder compression, and unstable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

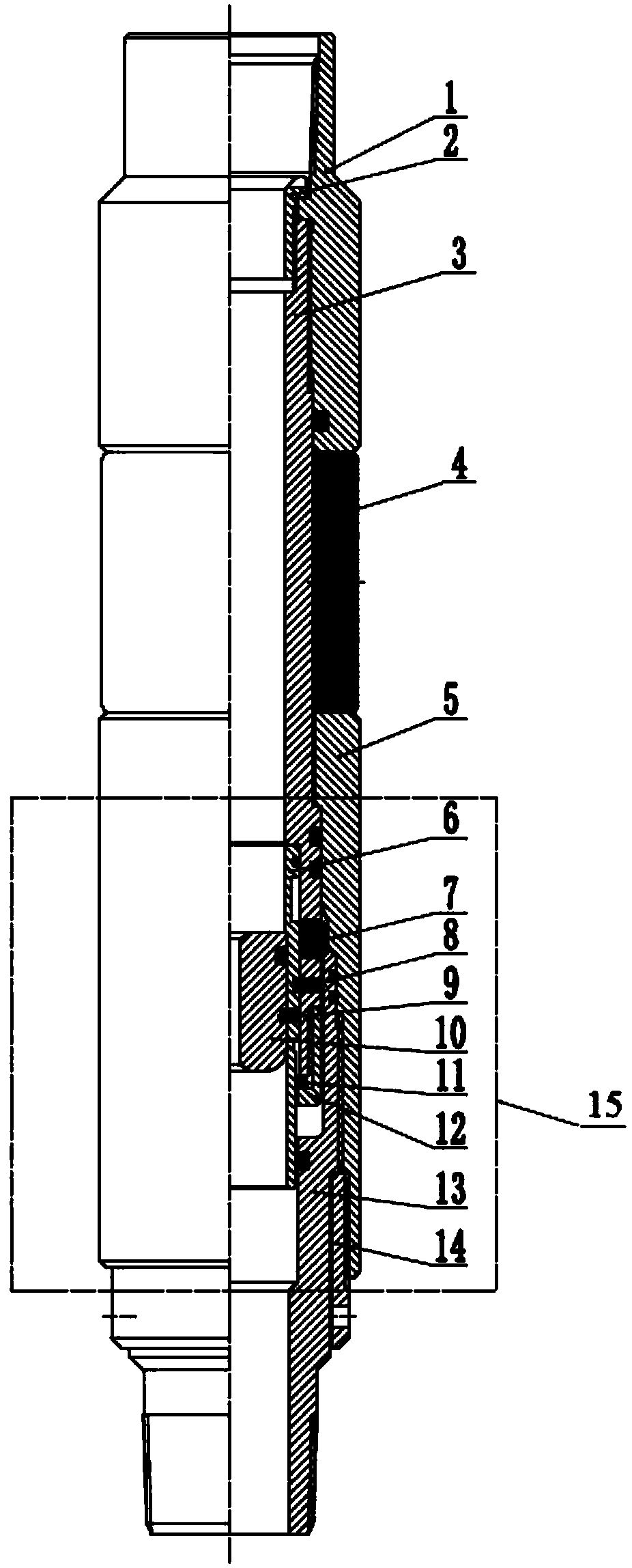

[0023] This embodiment provides a compression packer double-sliding sleeve setting and locking mechanism, such as figure 1 As shown, the double sliding sleeve setting locking mechanism 15 at least includes a central tube 3, a first sliding sleeve 6, a second sliding sleeve 10 and a protective cap 12. The first sliding sleeve 6 and the second sliding sleeve 10 pass through several The first scissors 9 are fixedly connected, the first sliding sleeve 6 and the central tube 3 are fixed by the second scissors 8, and the lower end of the central tube 3 is radially evenly distributed with a number of holes and built-in locking blocks 7, which are fixed on the central tube 3 The top protrudes outward, and can produce radial movement on the central tube 3. The bottom of the central tube 3 is threaded with the protective cap 12. There is a certain axial gap between the central tube 3 and the protective cap 12, which is used to fix the C-shaped ring 11. Axial displacement.

[0024] This...

Embodiment 2

[0029] On the basis of Embodiment 1, the outer surface of the first sliding sleeve 6 is provided with two annular grooves at the upper end and the lower end. At the height of the central pipe 3, the width of the groove at the lower end is larger than that of the C-ring 11. Before the compression packer is set, the protrusion of the locking block 7 is pushed against the groove at the upper end.

[0030] The space between the first sliding sleeve 6 and the second sliding sleeve 10 and the upper ends of the central tube 3 and the first sliding sleeve 6 are all sealed by sealing rings, and the equivalent shear surfaces of all the second shear pins 8 are less than or equal to all the first shear pins 8 The equivalent shear surface of a shear pin 9; the inner diameter of the C-shaped ring 11 in a free state is smaller than the outer diameter of the lower end of the first sliding sleeve 6, and the outer diameter of the C-shaped ring 11 is greater than the inner diameter of the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com