A pressure casing protection packer

A packer and casing technology, which is applied in the field of new casing protection packers, can solve the problems of uneven force on the rubber cylinder, decreased sealing performance, and no righting function of the packer, so as to achieve reliable setting and improved performance. The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

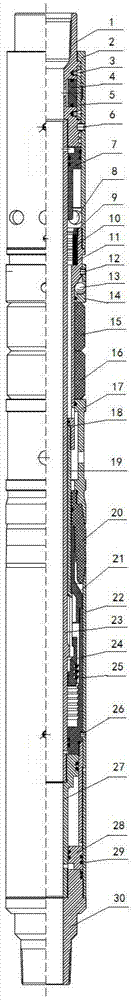

[0016] Such as figure 1 As shown, the present invention provides a pressure casing protection packer, comprising an upper joint 1 and a lower joint 30, the inner wall of the lower end of the upper joint 1 is threaded with an upper central pipe 23, and the outer wall of the lower end of the upper central pipe 23 is threaded. There is a lower central tube 27, the outer wall of the lower end of the lower central tube 27 is threadedly connected with the inner wall of the upper end of the lower joint 30, the outer wall of the lower end of the upper joint 1 is threaded with an outer cylinder 2, and a sleeve is provided between the outer cylinder 2 and the upper joint 1. The pressure ring 5 on the outer wall of the upper joint 1 forms a square cavity between the pressure ring 5 and the outer wall of the upper joint 1. The square cavity communicates with the liquid inlet hole opened on the upper joint 1. The inner wall of the lower end of the outer cylinder 2 is connected with the uppe...

Embodiment 2

[0020] On the basis of the embodiment, it should be further explained that the lock block 4 fixed in the square cavity by the screw 3 on the pressure ring 5 is provided in the square cavity. An opening is formed between the inner wall of the upper end of the setting head 14 and the outer wall of the liner 11 , and the opening is provided with righting balls 13 , and four righting balls 13 are evenly arranged along the circumferential direction of the liner 11 . The upper and lower contact surfaces of the lock block 4 and the upper joint 1 are respectively provided with a sealing ring, and two O-rings 29 are provided between the outer wall of the well-flushing piston 7 and the inner wall of the outer cylinder 2, and the well-flushing Two O-rings 29 are arranged between the inner wall of the piston 7 and the outer wall of the upper central tube 23, and an O-ring 29 is arranged on the contact surface between the lower end of the setting head 14 and the liner 11. An O-ring 29 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com