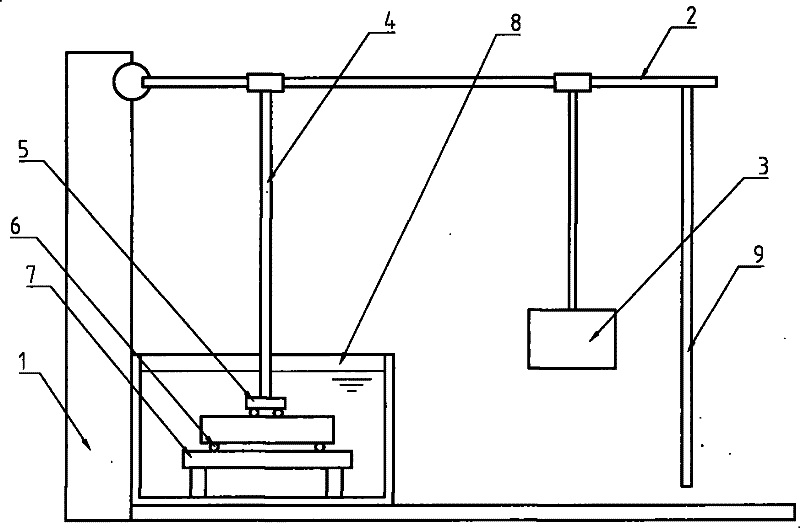

Loading equipment for corrosion test of concrete sample with stress action

A stress action and corrosion test technology, applied in the direction of material inspection products, mechanical devices, instruments, etc., can solve problems such as load attenuation, inaccurate loading load, spring stress relaxation, etc., to achieve reduced volume, convenient operation, and simplified calculations The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

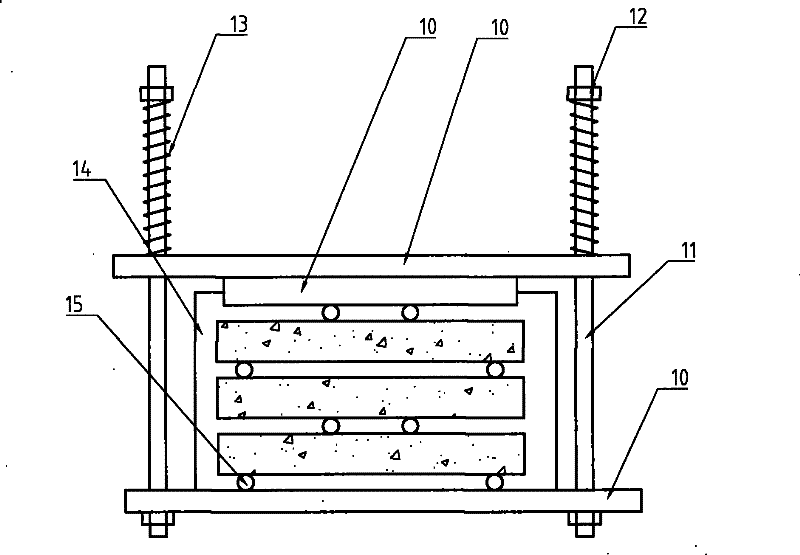

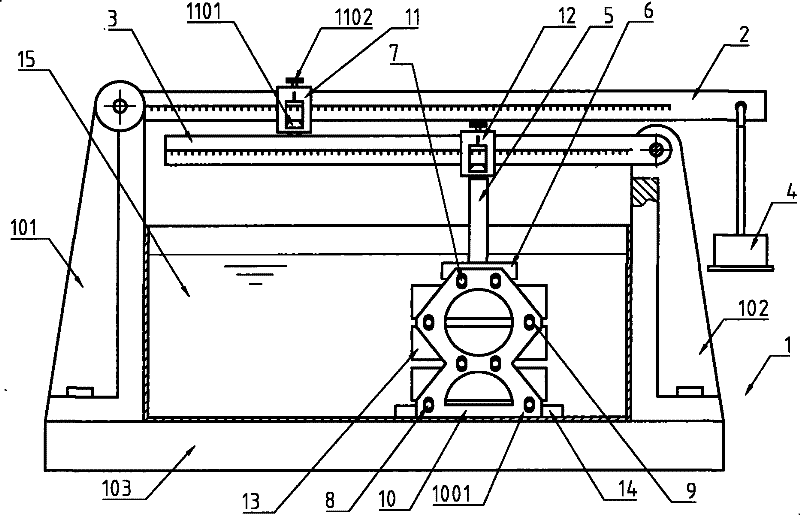

[0023] exist image 3 In the shown embodiment 1 of the loading equipment for the corrosion test of the concrete sample under stress, the loading equipment includes a frame 1, a scaled upper beam 2, a scaled lower beam 3, a loading weight 4, and a composition transmission. The pressure rod 5 of the force bar and the force plate 6, 2 upper force rollers 7, 2 lower force rollers 8, 4 middle force rollers 9 and 1 pair of force roller frames 10. One end of the upper beam 2 is hinged with the column 101 on the left side of the frame 1, and the other end hangs the loading weight 4, and the upper slider 11 that slides longitudinally along the upper beam is arranged in the middle of the upper beam 2. Lower crossbeam 3 is positioned at the following of upper crossbeam, and one end is hingedly connected with column 102 on the right side of frame 1, and in the middle of lower crossbeam 3, there is a lower slider 12 that slides longitudinally along lower crossbeam. The bottom of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com