Actuator based on multi-stage amplification principle

A technology based on actuators and principles, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of actuators being controlled by structural types and unable to meet requirements, etc. , to achieve the effect of increasing the effective contact area, improving the effect and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings of the description.

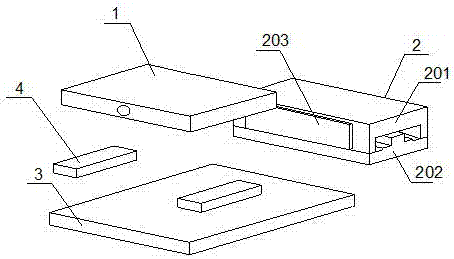

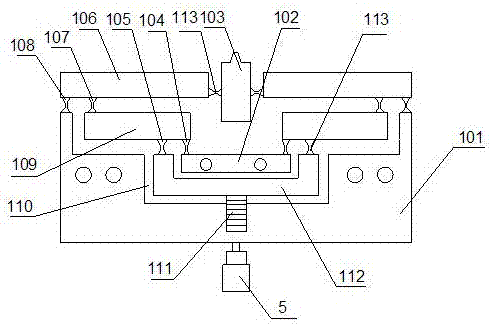

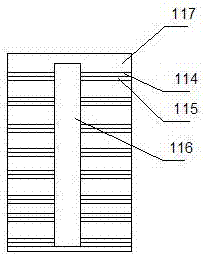

[0021] Such as Figure 1-4 As shown, an actuator based on the principle of multi-stage amplification includes a stator 1, a stator bottom plate 101, a fixed plate 102, a driving foot 103, a third fulcrum 104, a first fulcrum 105, a third lever 106, and a fourth fulcrum 107 , the fifth fulcrum 108, the second lever 109, the step groove 110, the power unit 111, the first lever 112, the sixth fulcrum 113, the internal electrode 114, the insulator 115, the external electrode 116, the piezoelectric ceramic sheet 117, the sixth fulcrum 118 , mover 2, mover body 201, mover base 202, wear-resistant ceramic bar 203, base 3, positioning backing plate 4, preloading device 5, micrometer head 501, contact ball 502 and square backing plate 503. The stator 1 is set on the base 3, the mover 2 is set on the base 3 and is in contact with the stator 1, the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com