A mems optical switch

A technology of optical switch and output optical fiber, which is applied in the field of optical switches, can solve the problems of unfavorable reduction of driving displacement, unfavorable packaging and integration, etc., and achieve the effects of improving packaging and integrable scalability, improving electrostatic driving ability, and reducing system stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

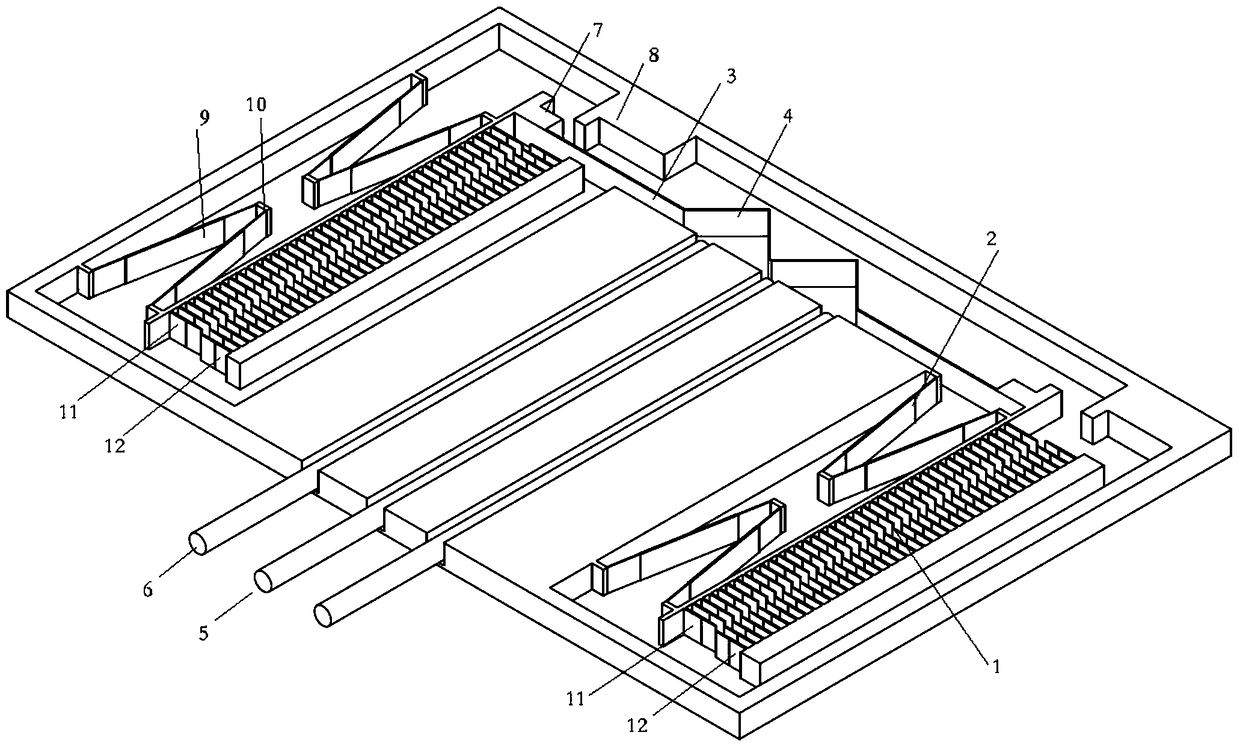

[0026] Such as figure 1 As shown, a MEMS optical switch includes a drive module 1, a folded beam 2, a support beam 3, a micro-mirror 4, an input optical fiber 5 and an output optical fiber 6, wherein the micro-mirror 4 is located in the middle of the support beam 3, and the support beam 3 Both ends of the drive module 1 are provided, and the side of the drive module 1 is provided with a folding beam 2;

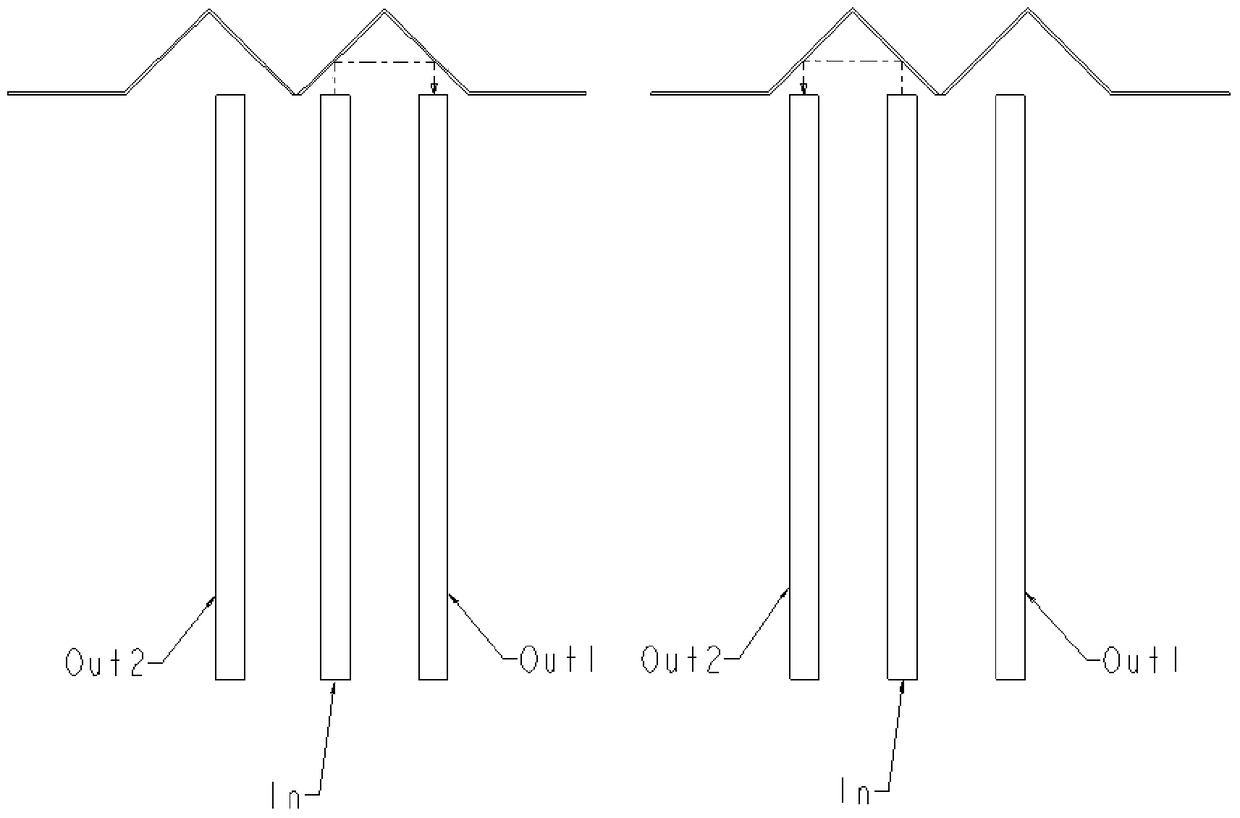

[0027] The drive module 1 arranged along the direction of the support beam 3 is an electrostatic comb drive structure, which is a wedge-shaped comb. Compared with the traditional rectangular comb, the wedge-shaped comb is beneficial to increase the drive displacement and reduce the drive voltage; the movable The non-overlapping initial arrangement of comb teeth and fixed comb teeth is beneficial to improve the lateral stability of the driving structure and increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com