Method for manufacturing split mounting type electric box and components thereof

An electrical cabinet, assembled technology, applied in the direction of electrical components, substation/switchgear board/panel/desk, switchgear, etc. Large workload and other problems, to achieve the effect of significant technological advancement, solid and reliable appearance, and reliable electrical grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

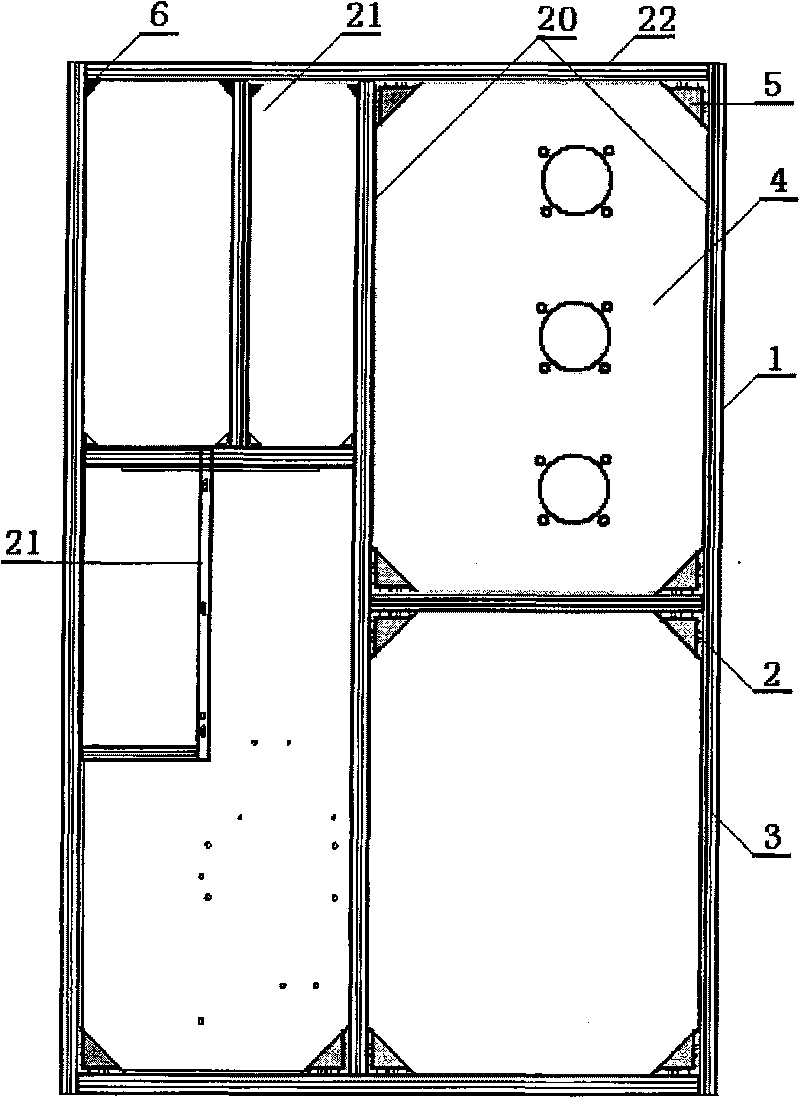

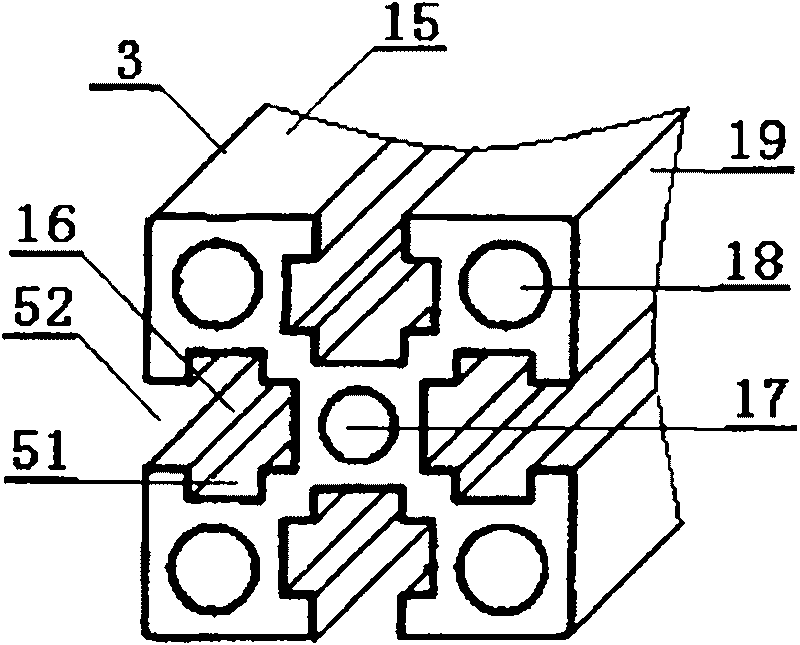

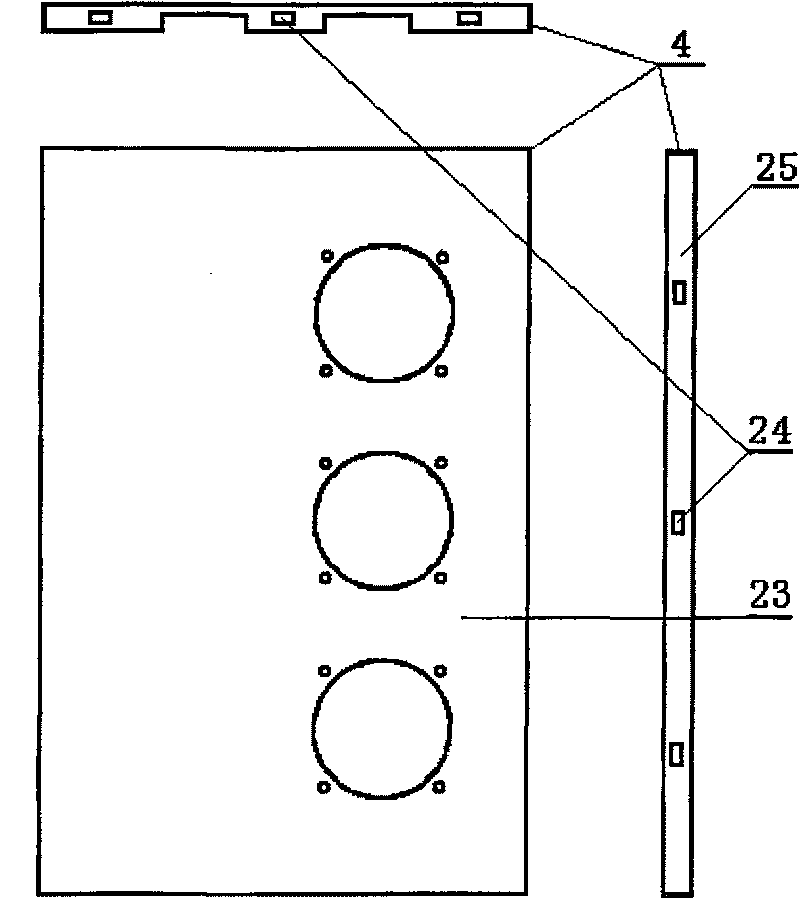

[0047] exist Figure 1 to Figure 22 Among them, the components for manufacturing the assembled electrical cabinet of the present invention are mainly composed of a main component 1 and an auxiliary assembly kit 2, which is characterized in that the main component 1 includes a frame main part 3 and a functional board 4, and the auxiliary assembly kit 2 includes a large right-angle Connecting seat 5, small right-angle connecting seat 6, "T" bolt 7, hexagon socket bolt 8, nut block 9, 90°diagonal block 10, slot connector 11, slot-type right-angle seat 12, "T"-shaped connection Plates 13 and "ten"-shaped connecting plates 14, wherein: the frame main part 3 is composed of square strip-shaped metal profiles 15, and an inner "T"-shaped bar groove 16, an axial center hole 17 and The process hole 18, the inner "T" shaped groove 16 is arranged on the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com