Grounding cutter of rail traffic grounding device

A technology for rail transit and grounding devices, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems affecting the efficiency of emergency repairs, such as the restoration of normal operation order, and achieve a simple and compact overall structure, easy operation, and shock load resistance. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

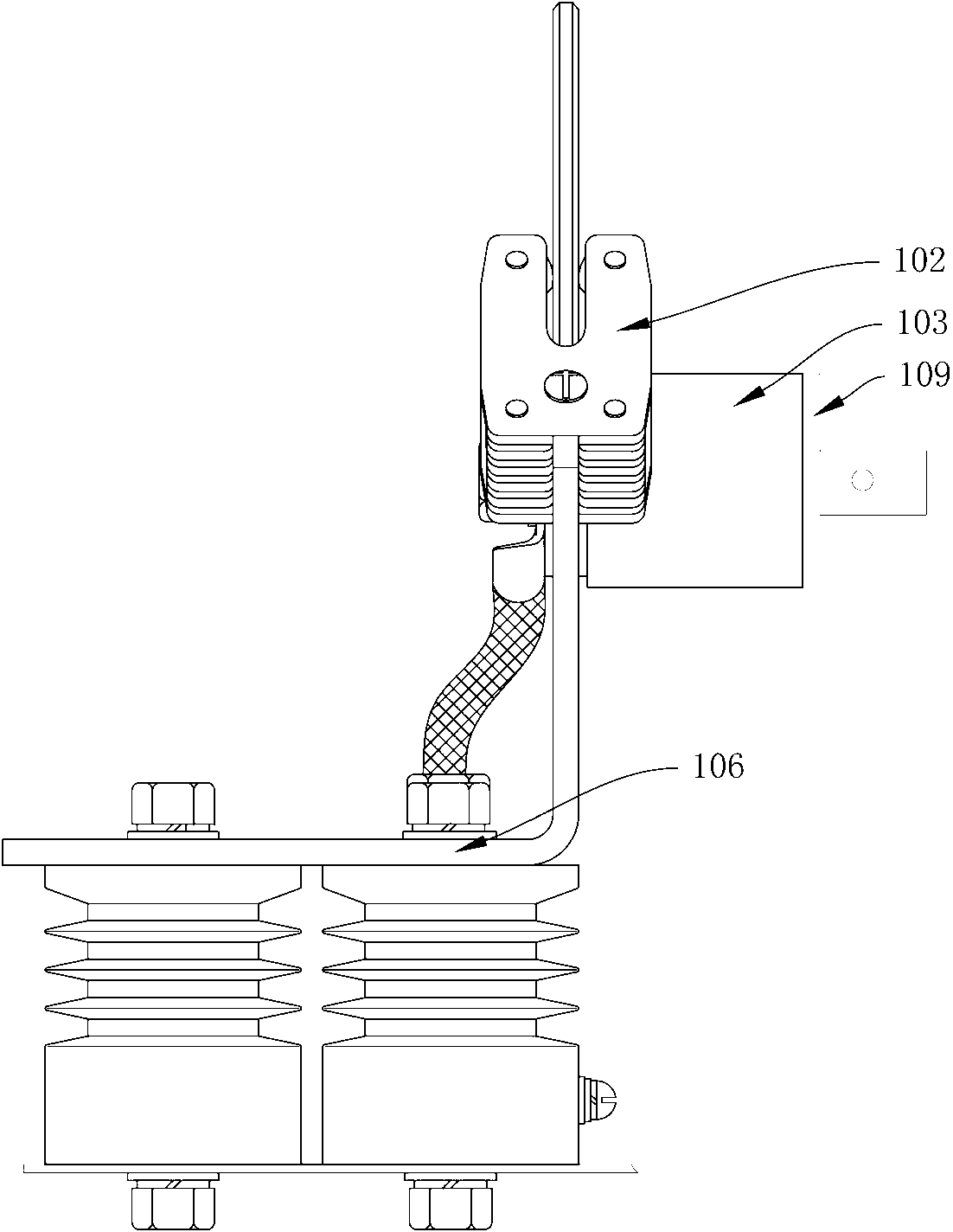

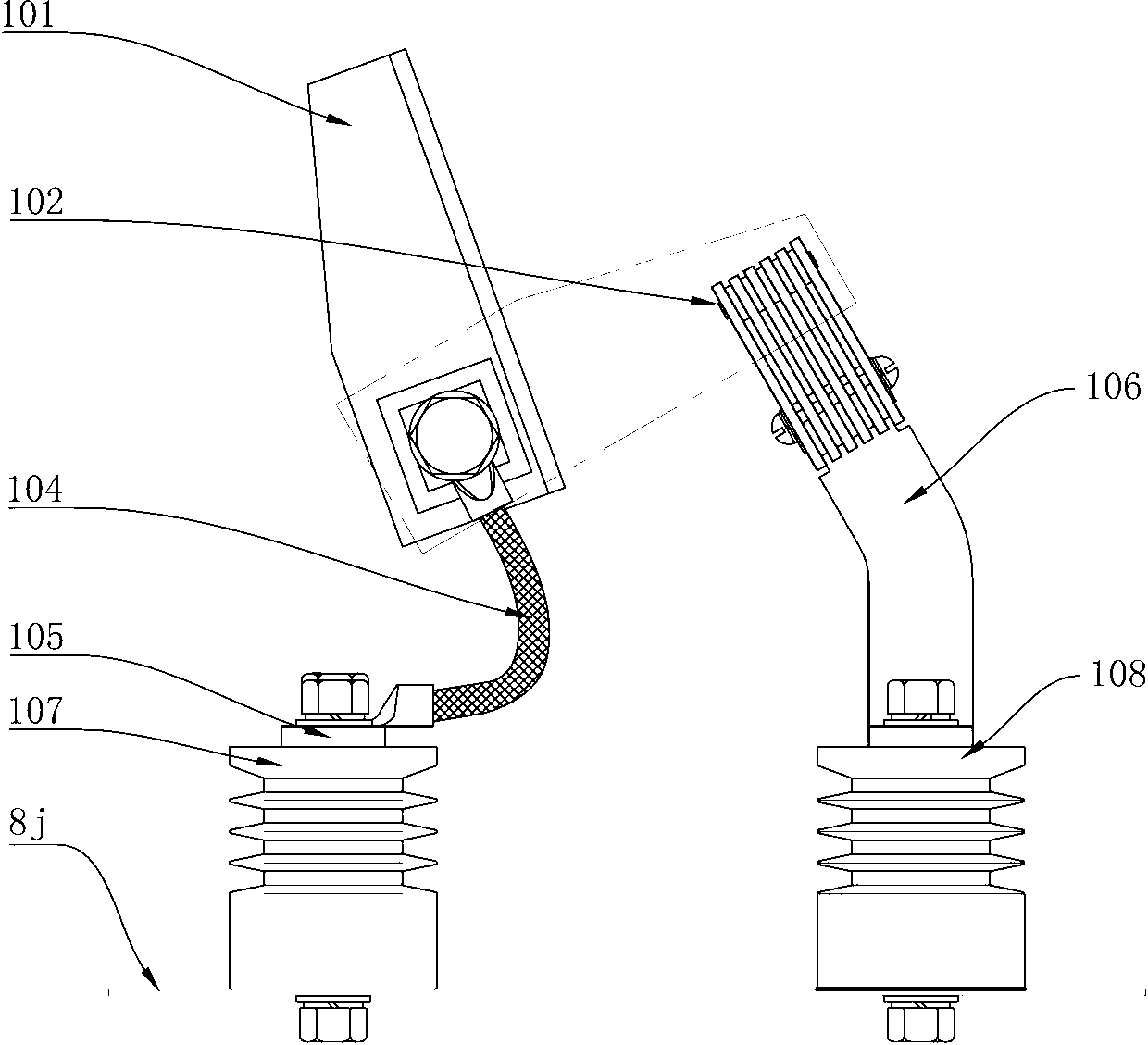

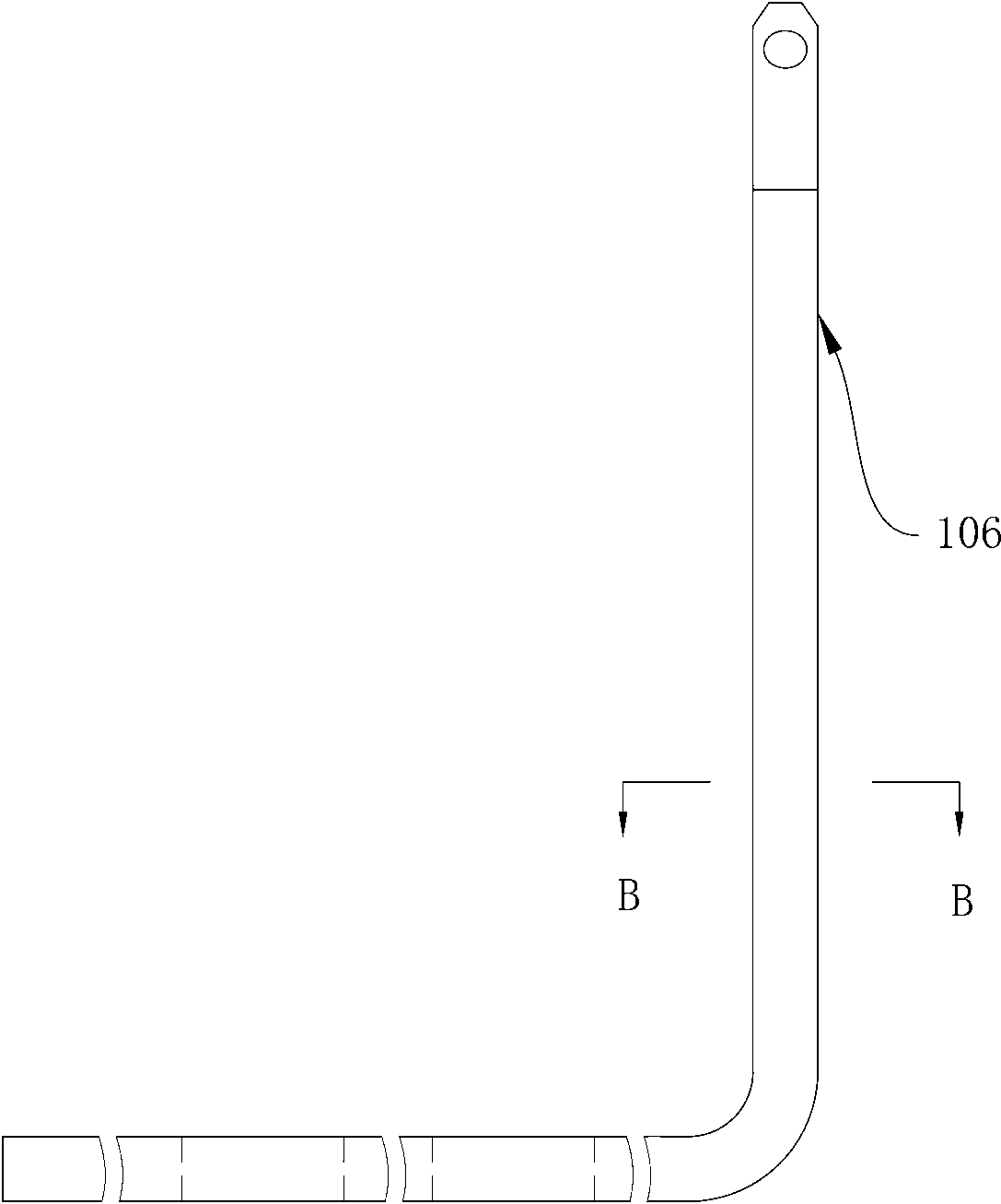

[0032] figure 1 , figure 2 It is shown that the grounding knife of the rail transit grounding device, the static contact knife is fixed as a whole by a plurality of concave-shaped copper sheets through rivets, and the static contact knife has an arc-shaped protrusion that is crimped with the moving contact knife 101 when the switch is closed; The static contact arm 106 is formed by bending a strip-shaped plate: it is composed of a horizontal section with the same width, a vertically upward section and an obliquely upward section, and three strip plates are connected end to end, and the strips of the obliquely upward section and the vertically upward section The shape plates are coplanar; the static contact knife 102 is fixed on the two sides of the top of the obliquely upper strip plate of the static contact arm 106 by screws; the horizontal section of the static contact arm 106 is fixed on two insulators 108 by screws;

[0033] The movable contact blade 101 is fixed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com