Automatically quantitative weighing and filling device

A charging device and automatic loading technology, which is applied to measuring devices, grinding devices, weighing equipment for automatic feeding/discharging, etc., can solve the problems of low production efficiency and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

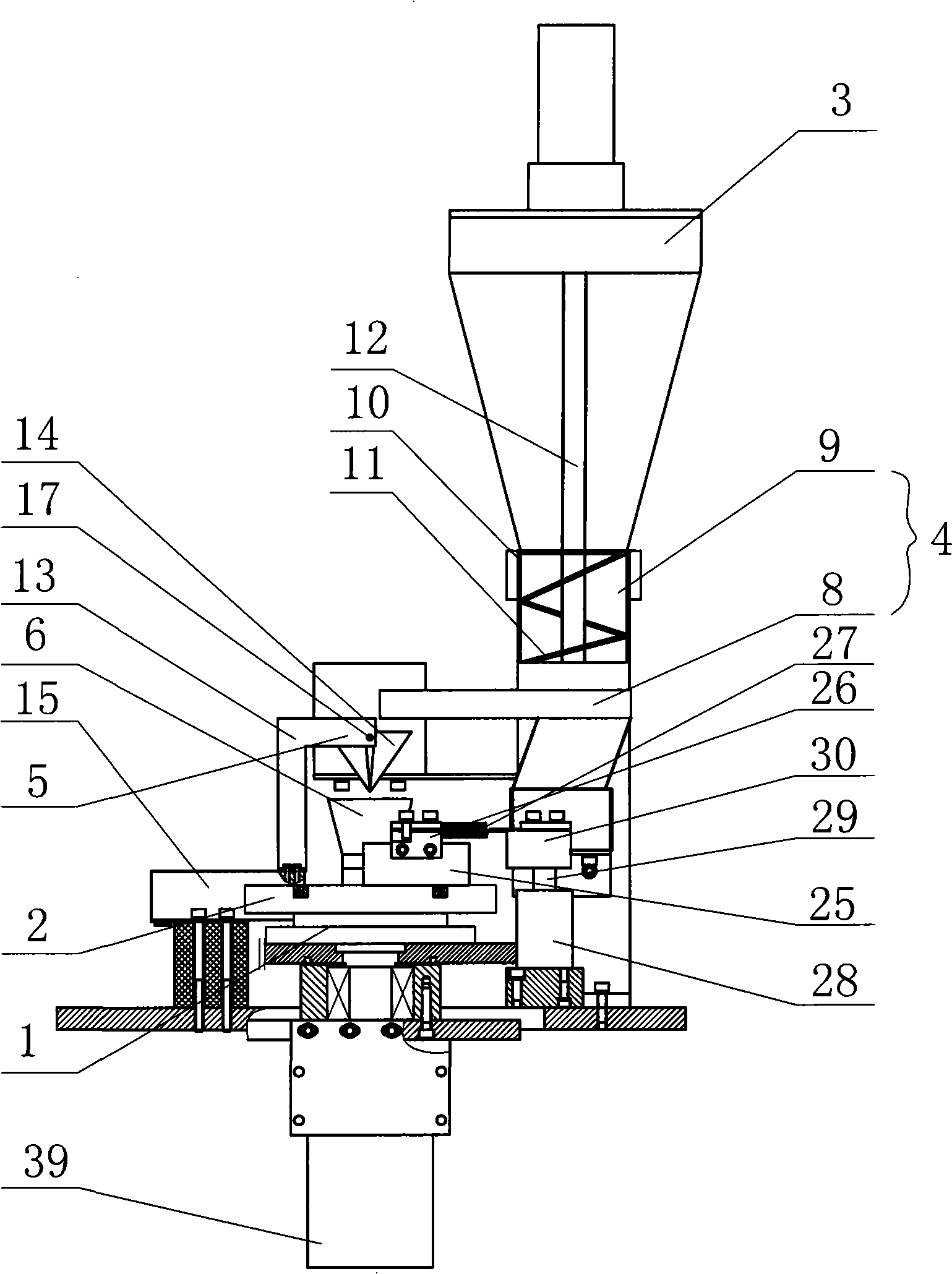

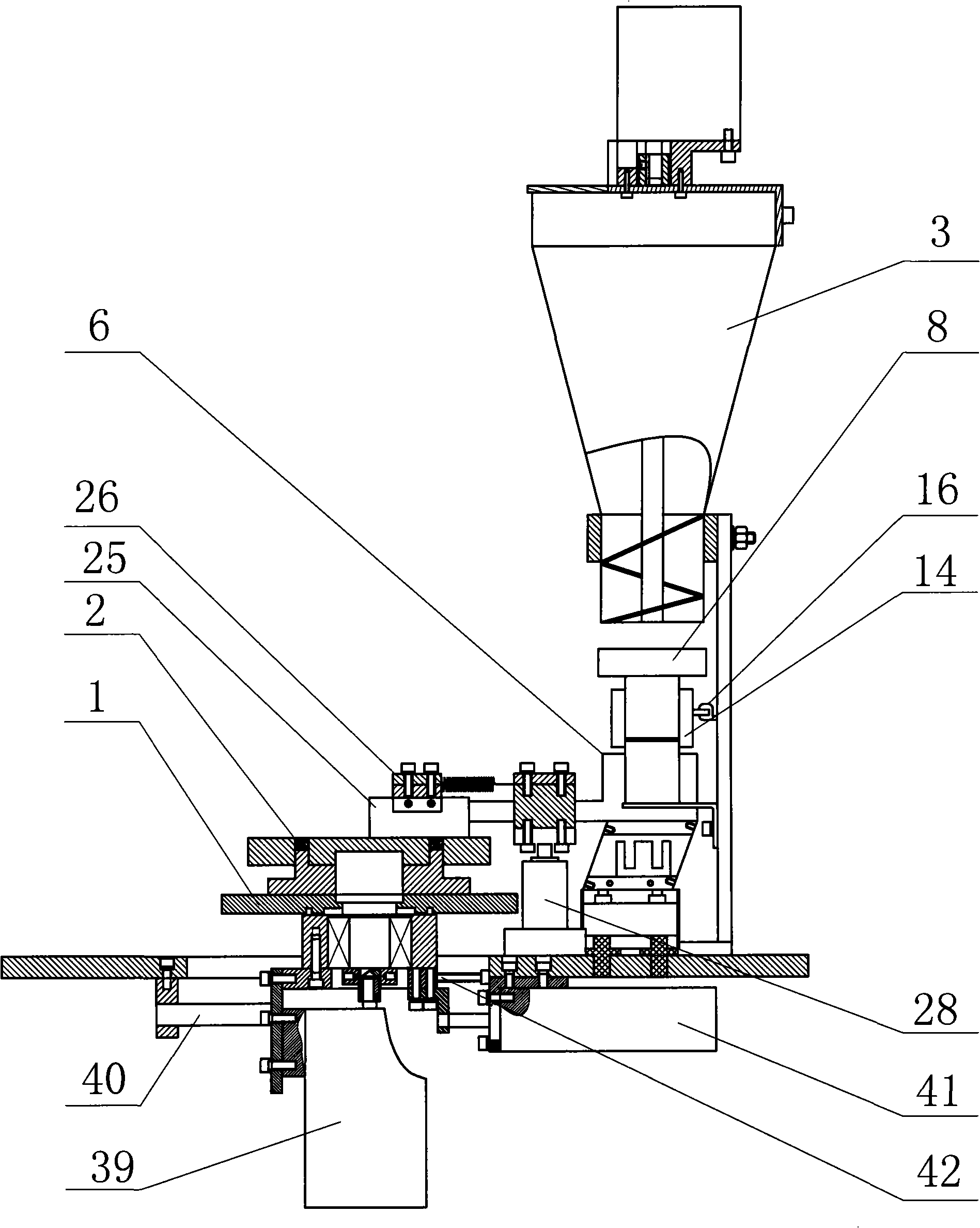

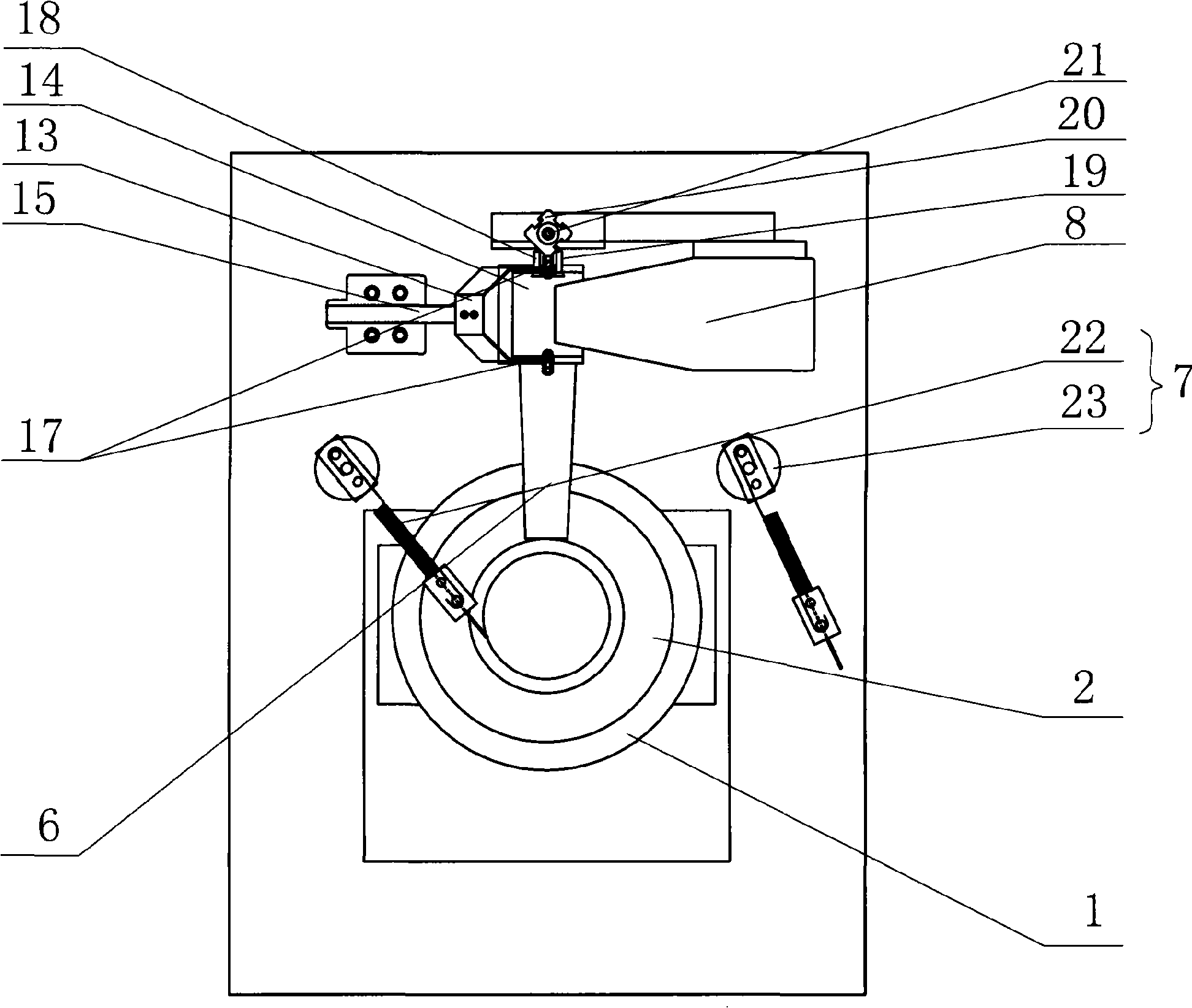

[0019] Such as Figure 1-Figure 3 As shown, the device transports the material quantitatively to the rotating mold 2 after quantitative weighing. The device includes a silo 3 fixed on the main body of the device for article supply and a supply part 4 arranged below the silo 3. In the supply part Downstream of 4, the main body of the device is fixedly equipped with a metering and conveying device 5 that quantitatively measures the articles from the supply part 4 and carries out the next stage of conveying the metered articles. Below the metering and conveying device 5, the main body of the device There is a linear feeder 6 that receives the items from the metering conveying device 5 and conveys the articles to the mold 2; in order to ensure that the articles in the metering conveying device 5 reach the set weight and after reaching the set weight, stop the supply part 4 Supply the material to the metering and conveying device 5 and control the metering and conveying device 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com