Oil box respiration device

A breathing device and oil tank technology, applied in the field of transformers, can solve problems such as seepage from the sealing surface on the top of the oil tank, high technical requirements for radiators, dirty transformers, etc., and achieve the effects of easy processing, reduced moisture content, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

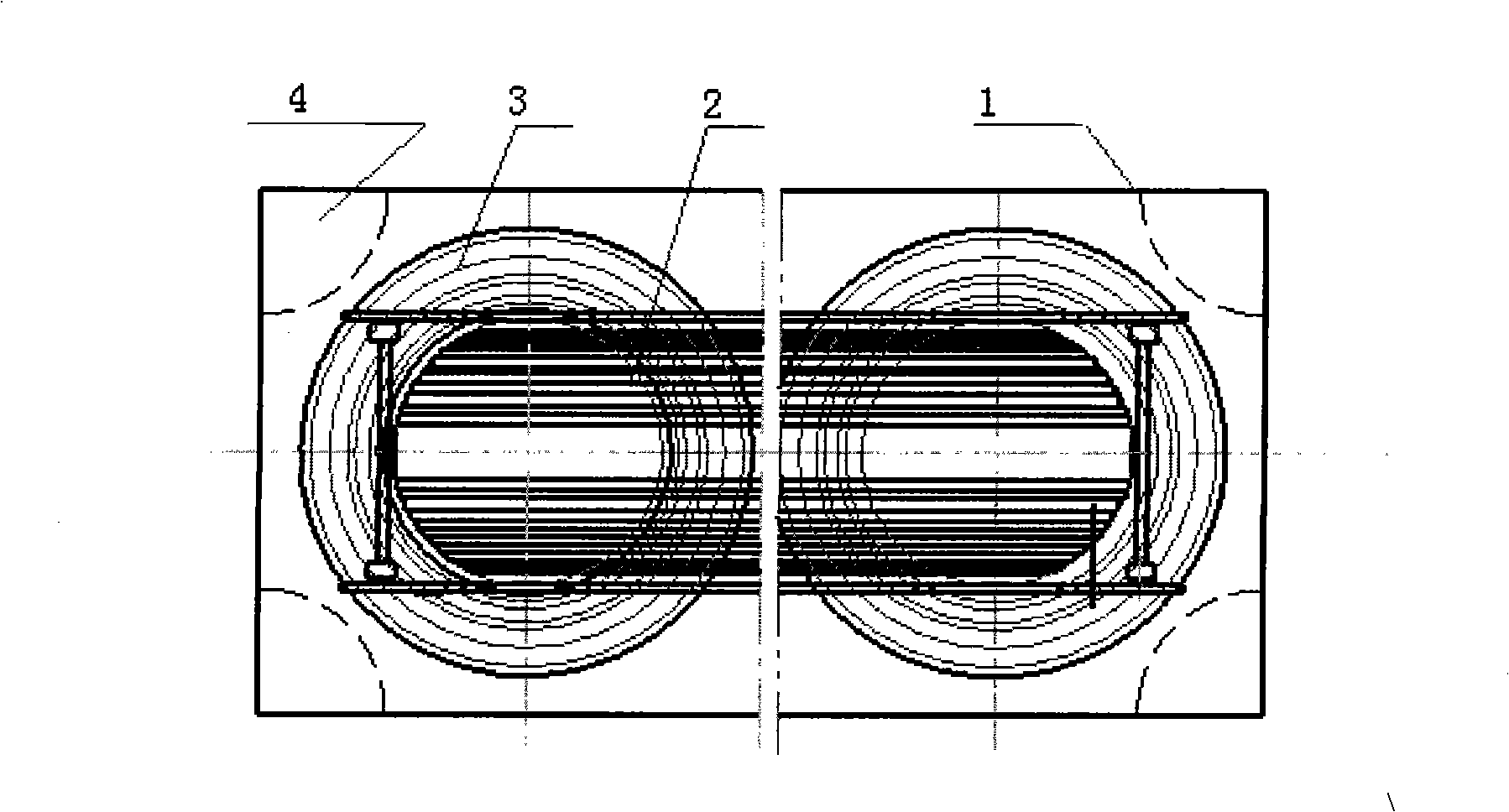

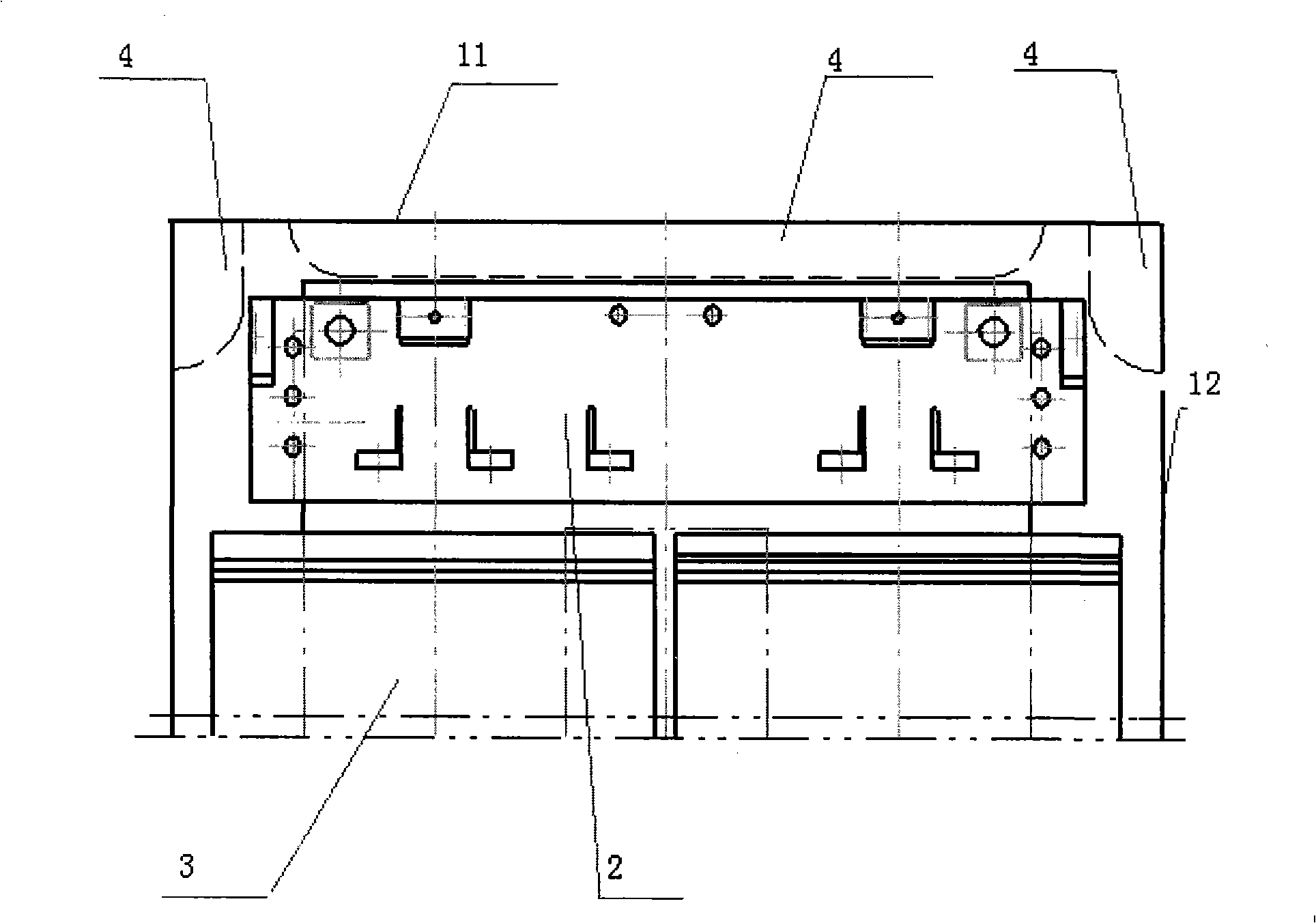

[0025] The present invention is described in detail below in conjunction with accompanying drawing: As shown in the figure, the present invention comprises the cuboid fuel tank 1 that is made of tank cover 11, tank wall 12, tank bottom 13, and the center of cuboid fuel tank 1 is provided with iron core 2, and the periphery of iron core 2 The coil 3 is wound, and at least one capsule 4 is arranged in the cuboid oil tank 1 .

[0026] The above-mentioned capsule 4 is arranged at the junction of the case cover 11 and the case wall 12 . The above-mentioned capsule 4 is arranged at the junction of the box bottom 13 and the box wall 12 .

[0027] The above-mentioned capsule 4 is strip-shaped or ring-shaped.

[0028] Above-mentioned capsule 4 is a sealed capsule. Fill the sealed capsule with dry air or nitrogen.

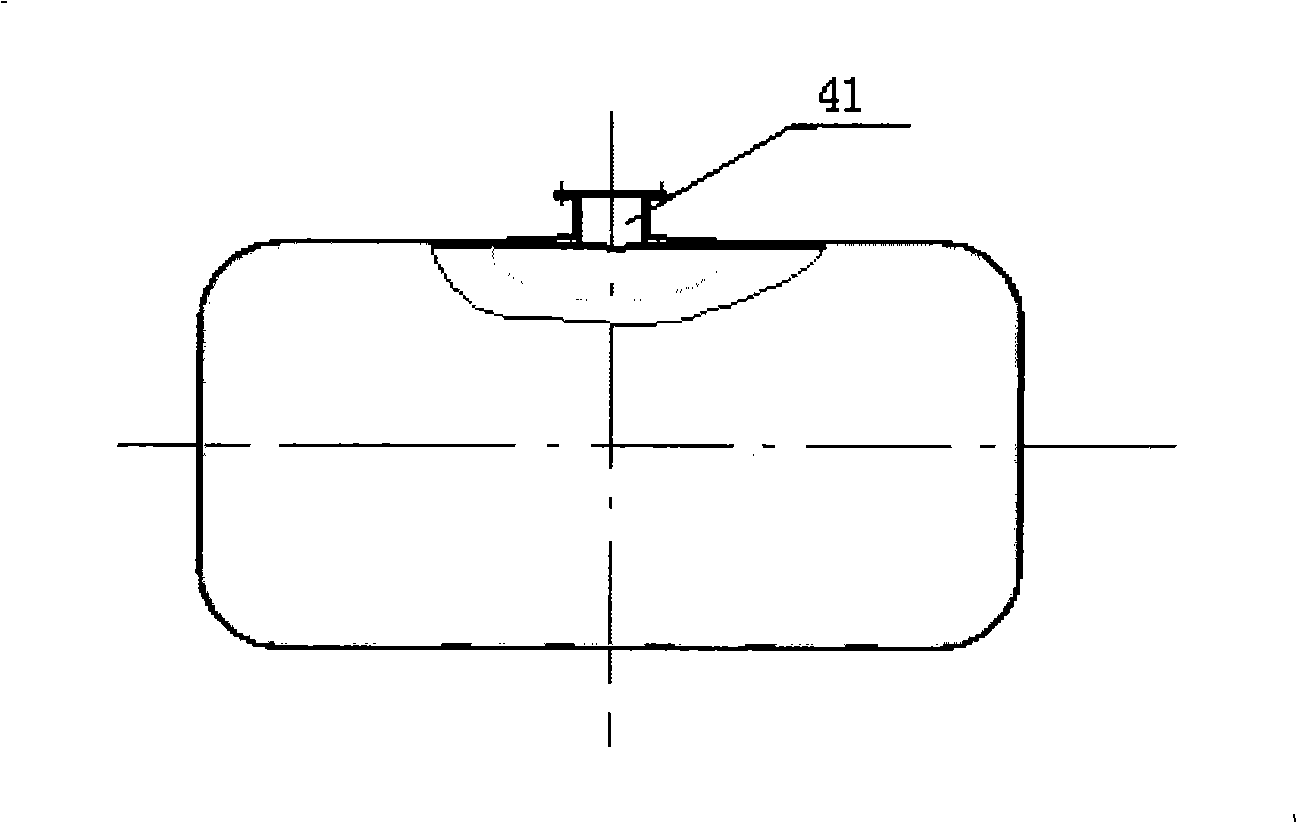

[0029] The above-mentioned capsule 4 is an open capsule. The open end 41 of the open capsule is connected to the moisture absorber 6 through the connecting pipe 5, and a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap