Sun wing hinge moment testing device

A technology of hinge moment and testing device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems that affect the cooperation relationship, the working conditions of the friction pair of hinge components are difficult to analyze and determine, and the hinge cannot be accurately calculated. Drive torque and other issues to achieve the effect of small temperature drift, good load matching performance and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

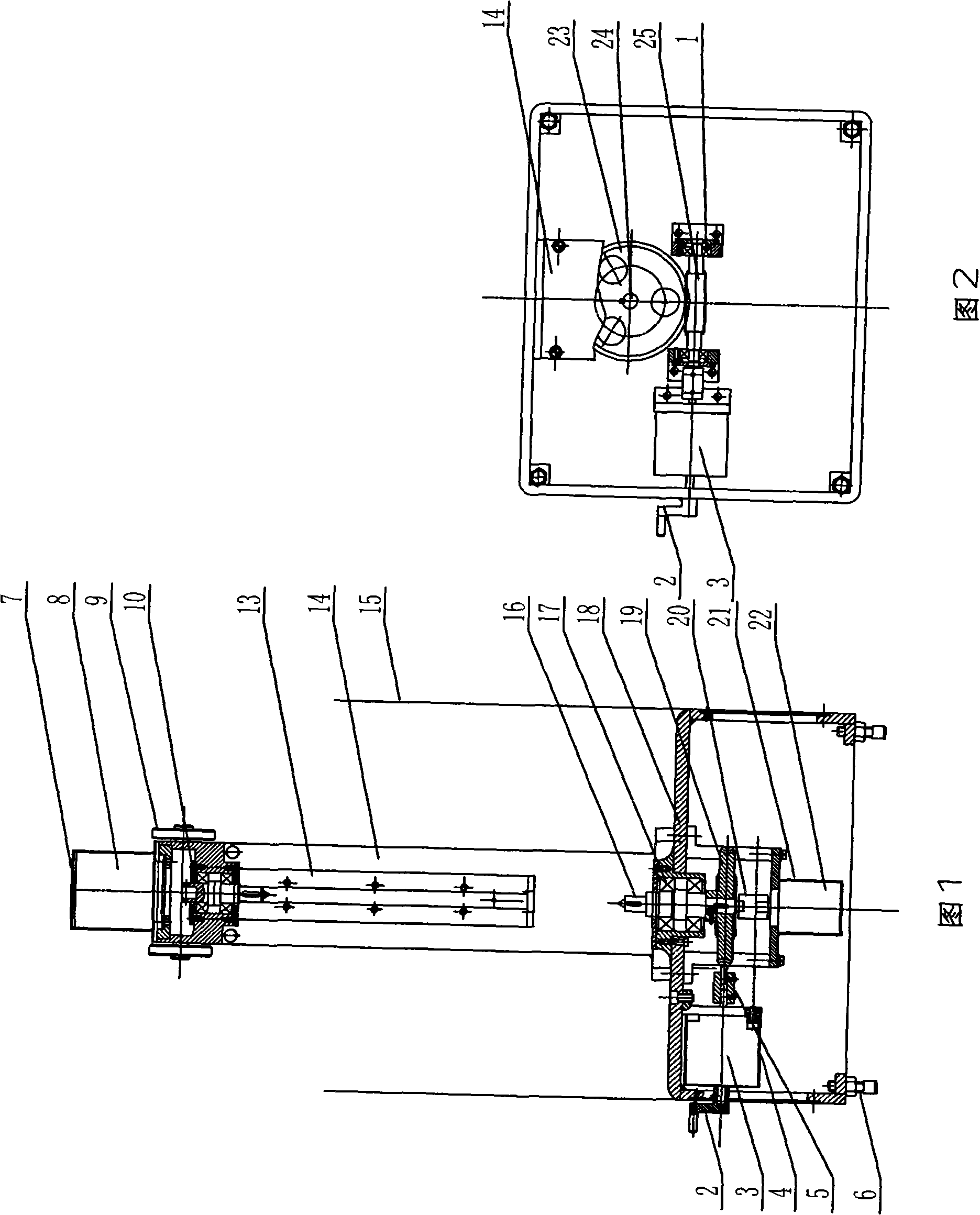

[0017] Referring to Fig. 1~2, the present invention comprises motor 3, support 14, base 18, speed reducer 19, base 18 is vertically fixedly connected with the support 14 that is provided with rack 13, and base 18 is provided with fixed top 16, base 18 Motor 3 and reducer 19 are provided inside. Motor 3 is a stepping motor with two shaft extensions. Supported by the bearing 1, the middle part of the main shaft 24 of the reducer 19 is fixed to the worm wheel 23, one shaft end is fixed to the fixed top 16, and the other shaft end is fixed to the angle sensor 22 by the coupling 20, the worm wheel 23 meshes with the worm 25, and the main shaft 24 is supported by bearing 17. The bracket 14 is provided with a movable top 10 which is movably connected with the rack 13 . Adjusting knobs 9 are provided on both sides of the movable top 10 , and a torque sensor 8 is provided at its top. The bottom plate of base 18 is fixedly connected with 4 adjustable legs 6, and the shells of motor 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com