Roller brush and method for production thereof

A technology of rolling brushes and bristles, applied in the field of rolling brushes and their production, can solve the problems such as the inability to guarantee the sameness of material types, and achieve the effect of high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

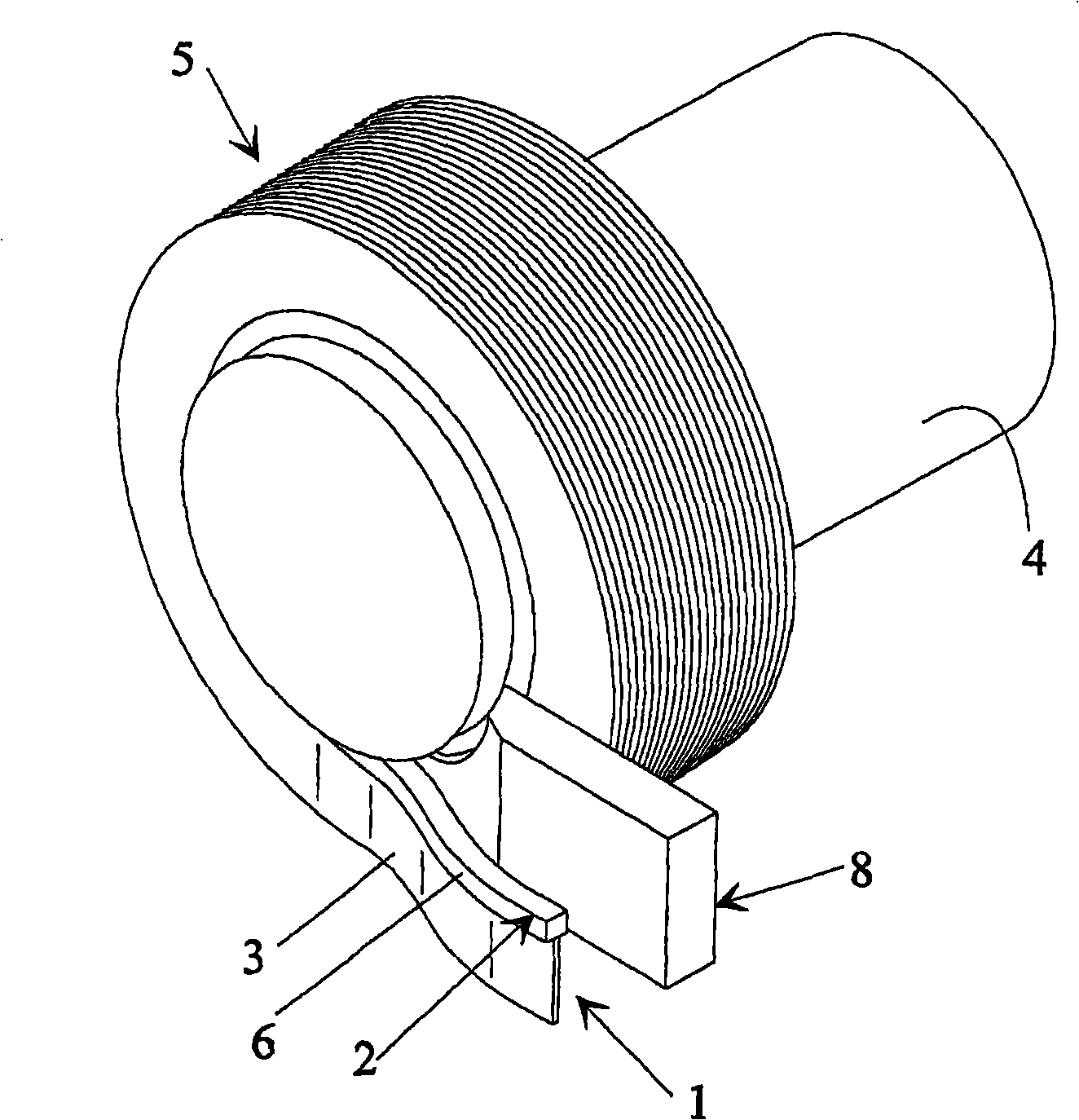

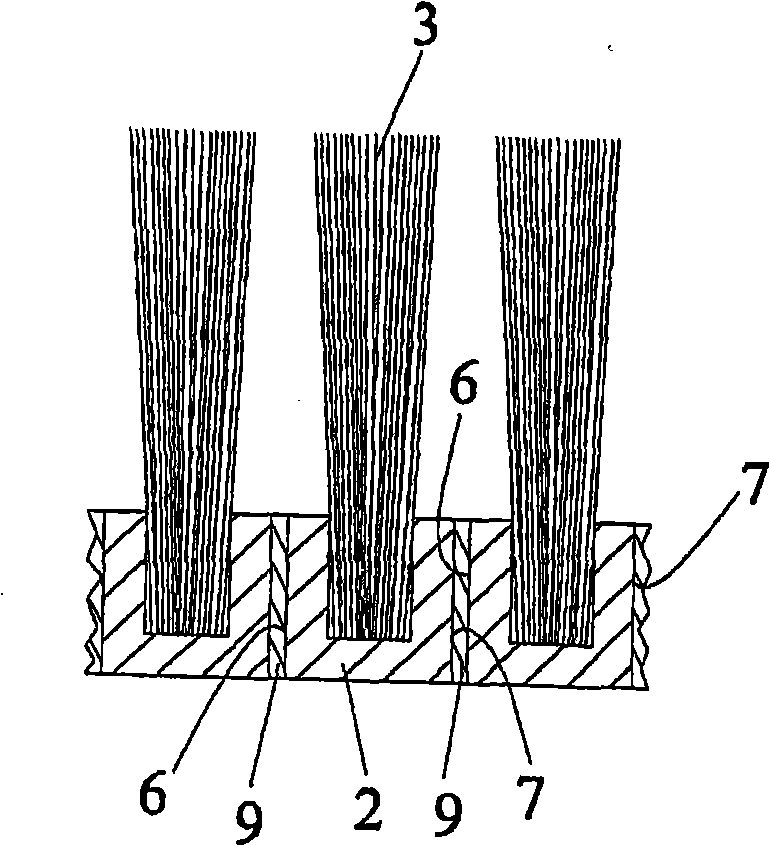

[0023] figure 1 The helical winding of a continuously produced strip brush 1 is shown, wherein a holding profile 2 made of plastic accommodates a bristle assembly 3 . The strip brush 1 is wound on the winding pin 4 . With the increase of the axial length of the roller brush 5, the roller brush 5 can be pushed out on the axial length of the winding pin 4, because with the winding, the sides 6, 7 of the retaining profile 2 are glued and / or welded to each other, and at the same time Compared figure 2 , thus forming a self-supporting roller so that it does not use a core.

[0024] The method according to the invention also makes it possible to produce roller brushes 5 of any desired axial length, since the continuously produced roller brushes need only be cut to length in a simple manner.

[0025] The bonding of the sides 6 , 7 can be effected by means of a suitably formed device 8 , for example under the action of pressure and / or heat.

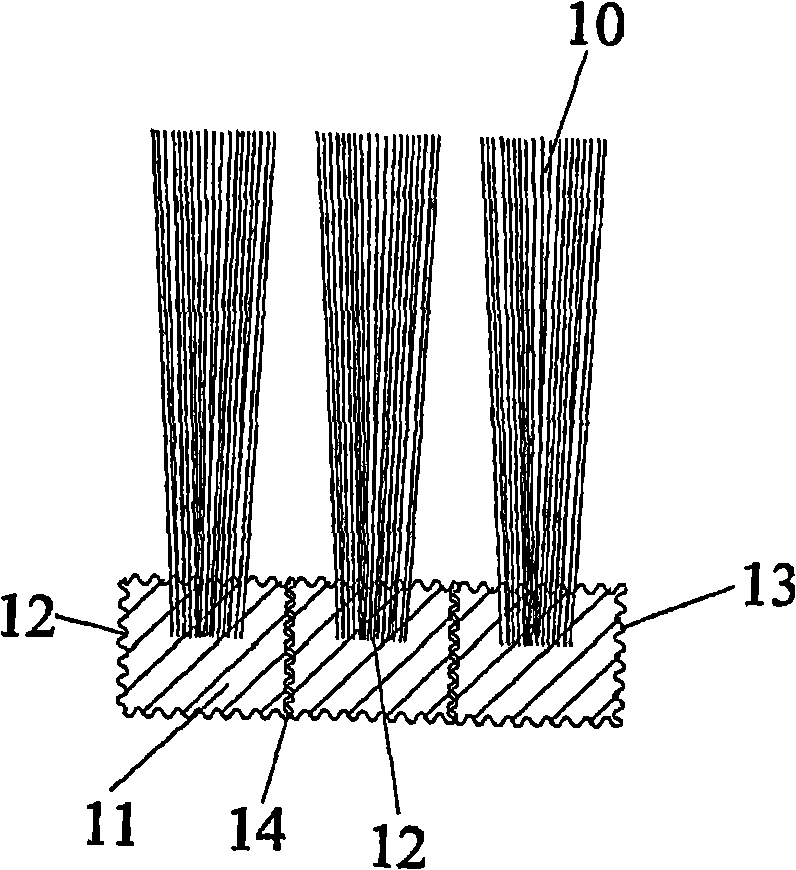

[0026] figure 2 An axial section th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com