Cyclonic separation apparatus

A technology of cyclone separation and cyclone separator, which is applied in the direction of cyclone device, device whose axial direction can be reversed, suction filter, etc., and can solve problems such as cyclone clogging and dust gas cannot be loaded smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

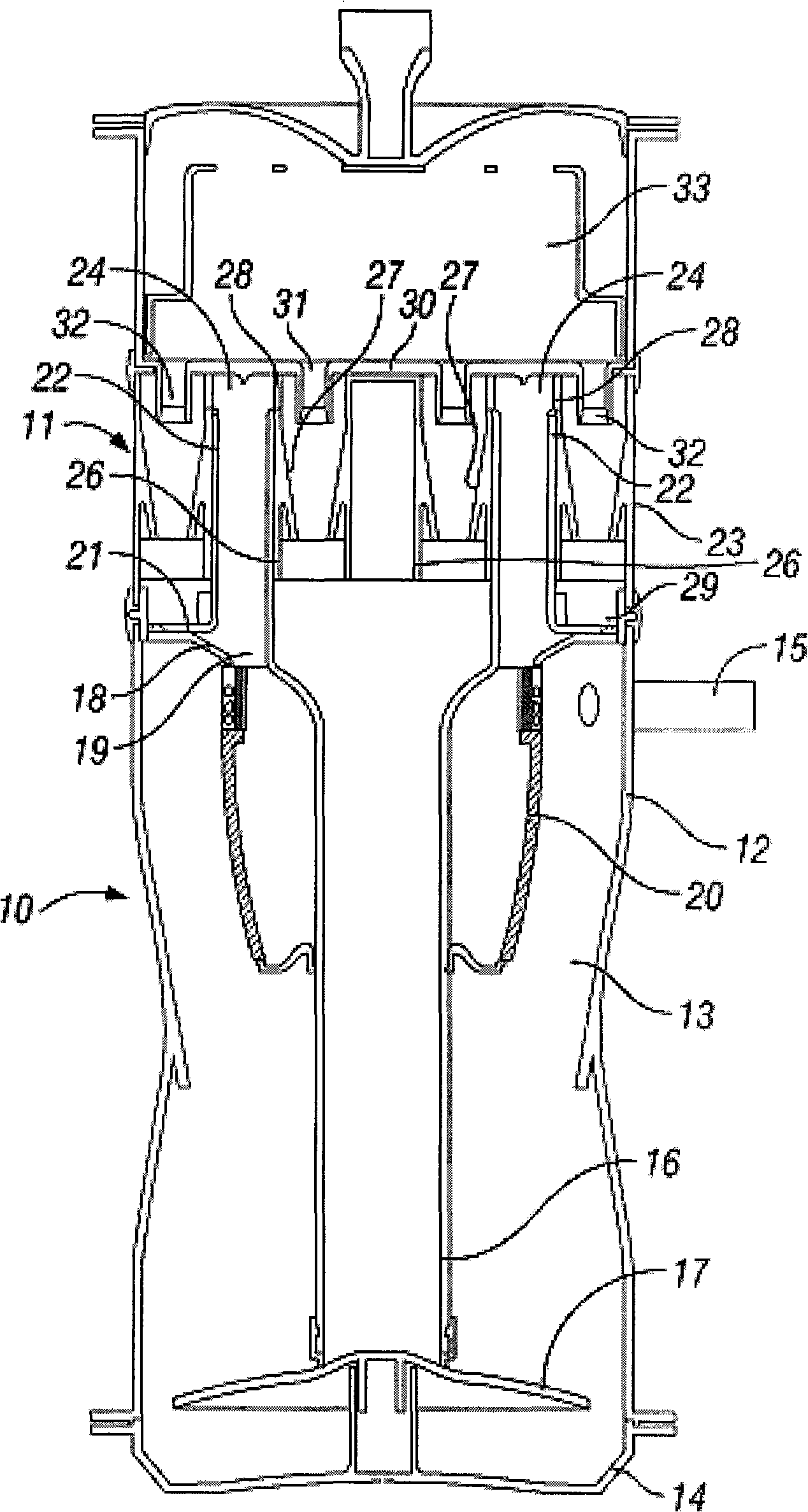

[0032] Refer to the attached figure 1 , showing a detached section of an upright vacuum cleaner. The detachment is mounted to a chassis (not shown) containing a handle, the lower end of which is pivotally connected to a wheel-shaped floor cleaning head containing a rotatable agitating brush.

[0033] The separation part comprises a substantially cylindrical upright housing housing at its lower and upper ends respectively a first separation step 10 and a second separation step 11 fluidly connected to the first step 10. downstream.

[0034] The first step 10 comprises a tubular side wall 12 defining a cyclone chamber 13 of circular section. The lower end of the tubular side wall 12 is provided with a closure 14 which can be opened to allow the chamber 13 to be emptied of separated dirt and dust.

[0035] An inlet duct 15 for conveying dirt and dust laden air from the floor cleaning head extends tangentially into the upper end of the tubular side wall 12 of the first step 10 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com