Intermittent coating method and apparatus

A coating method and coating technology, which can be applied to the device and coating of the surface coating liquid, which can solve the problems of insufficient responsiveness of the suction valve, inability to suppress the tilt state, and the inability to coat the coating liquid with a thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the intermittent coating method and the intermittent coating apparatus according to the embodiment of the present invention will be described in detail based on the drawings. In addition, the intermittent coating method and intermittent coating apparatus according to the present invention are not limited to the following embodiments, and can be appropriately modified within a range that does not change the gist of the invention.

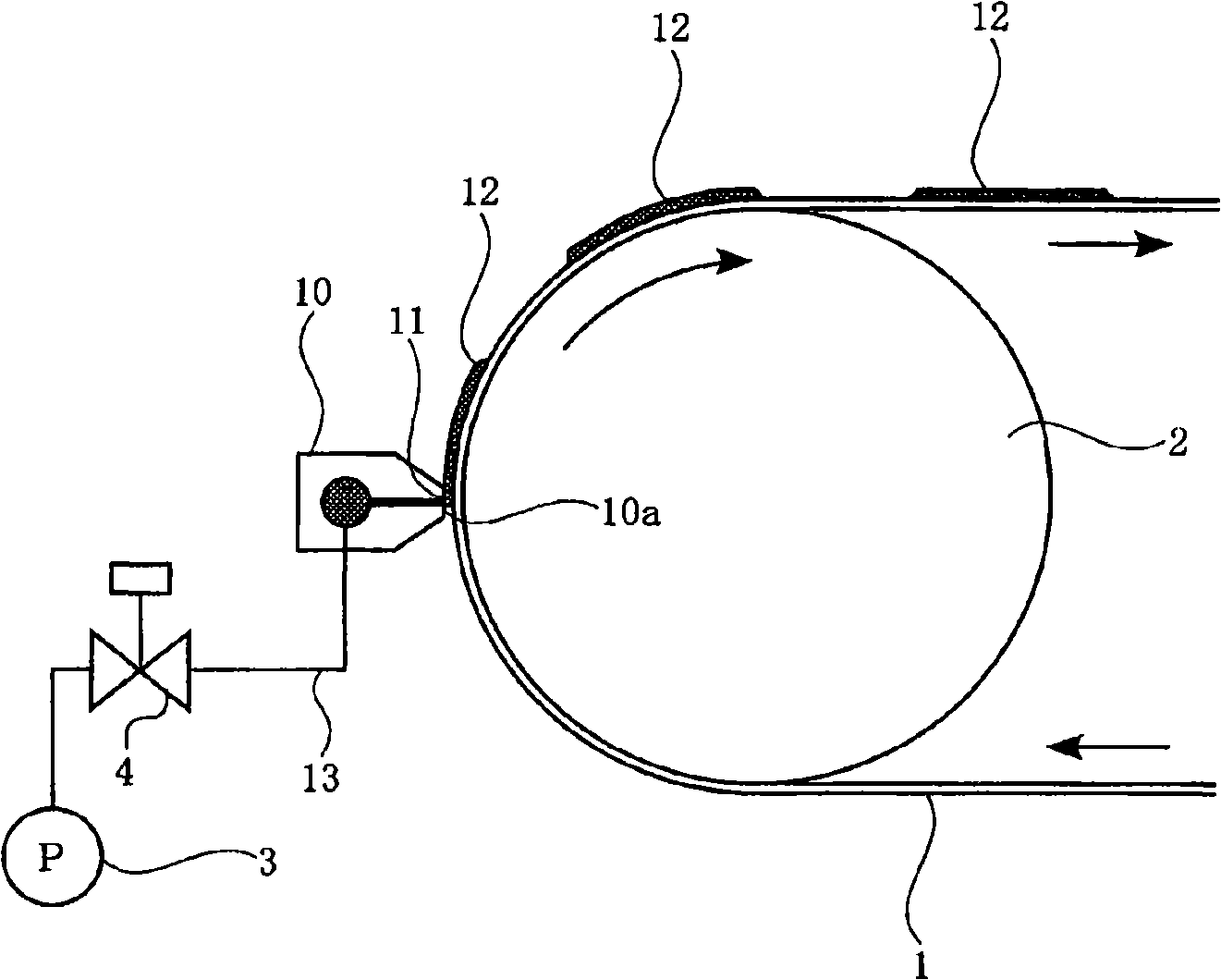

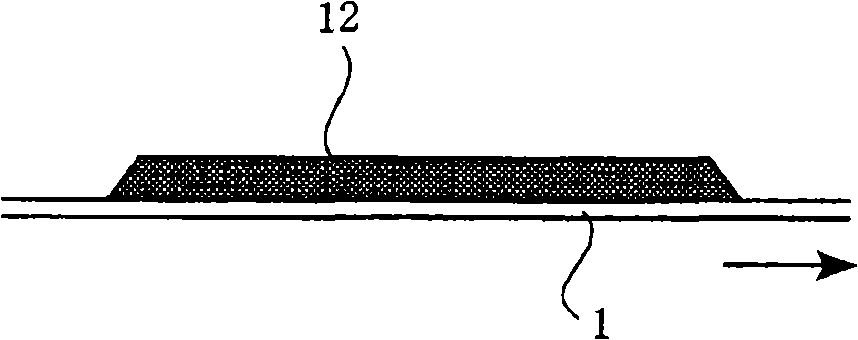

[0052] Such as Figure 4 As shown, in this embodiment, while the substrate 1 is hung on the support roll 2 and moved, the control device 21 is used to control the conveying device 20 that conveys the coating die 10.

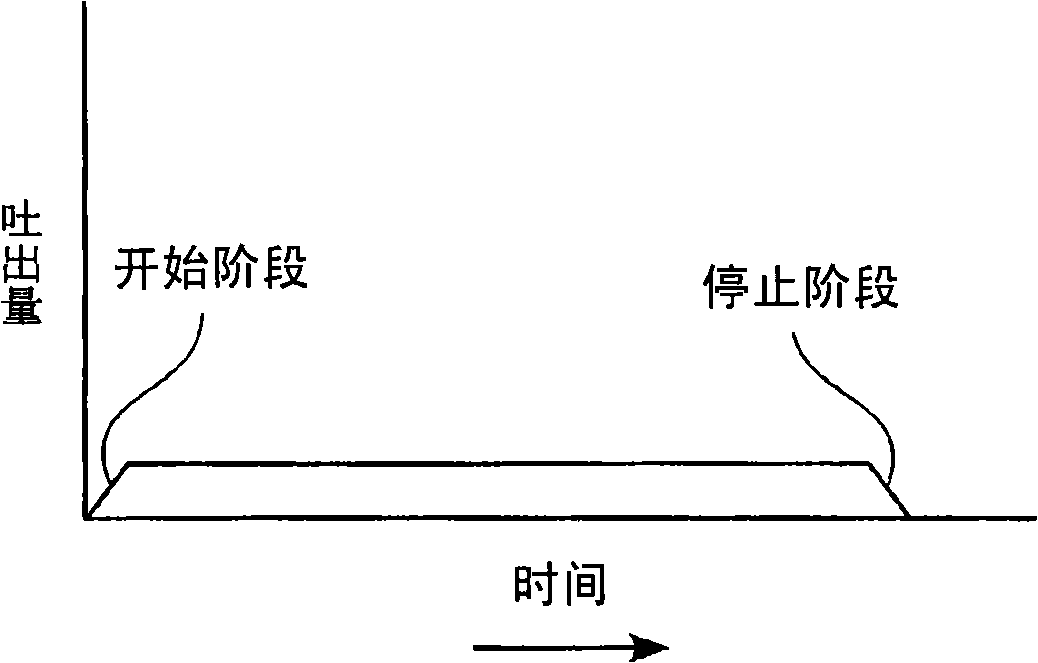

[0053] The front end surface 10a of the coating die 10 is guided downward to a position where the front end surface 10a of the coating die 10 is spaced apart from the substrate 1 moved in the above manner by a desired distance, while making the coating The die head 10 moves in the same direction as the base material 1 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com