Electronic device and method for manufacturing this device

A technology of electronic devices and electrode holders, which is applied in the direction of circuits, electrical components, and electrical solid devices, and can solve problems such as poor connection, large volume of anisotropic conductive resin, and detachment of button bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In all the drawings for explaining the embodiments, parts having the same functions are identified by the same reference numerals so that their repeated descriptions will be omitted.

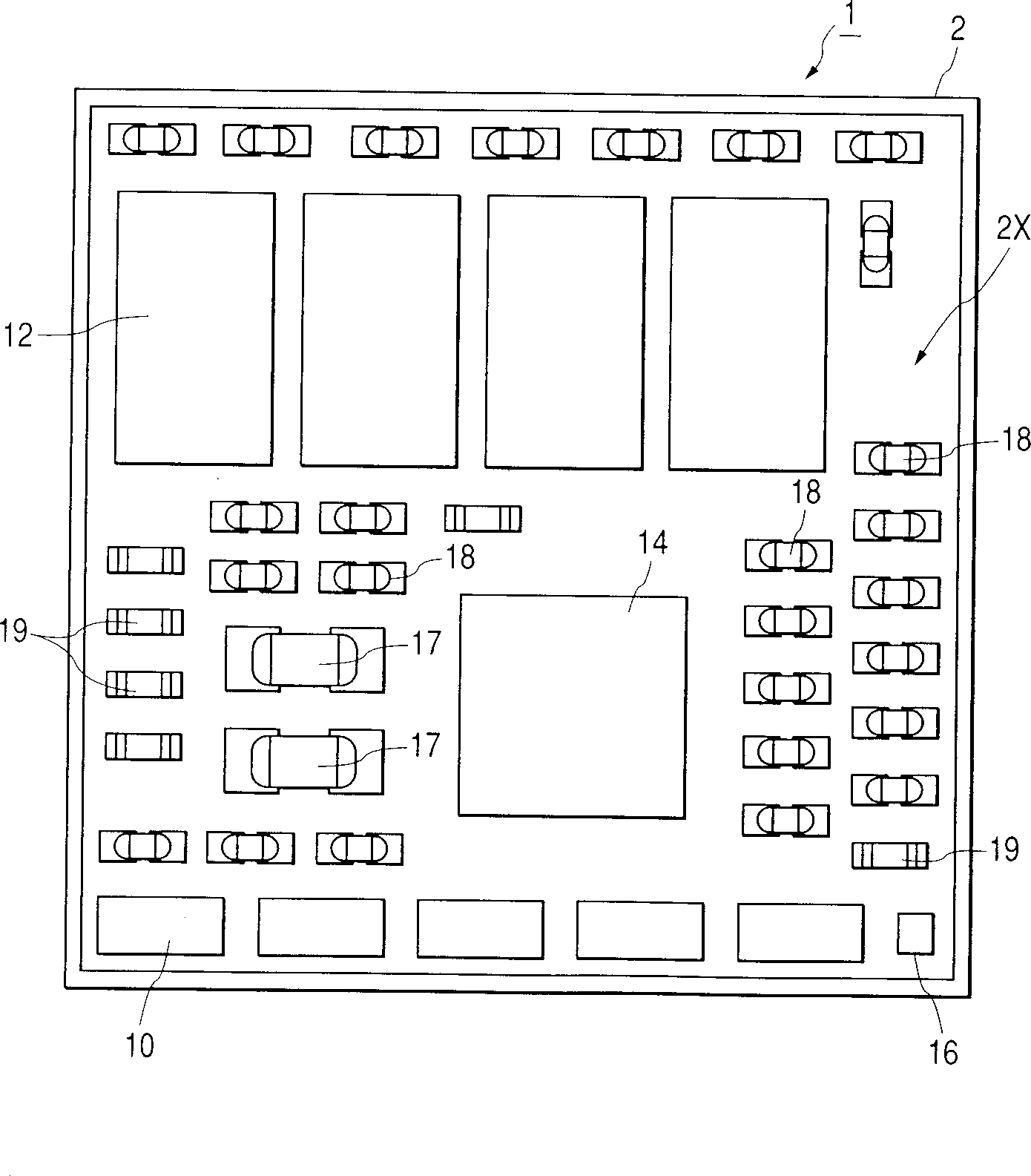

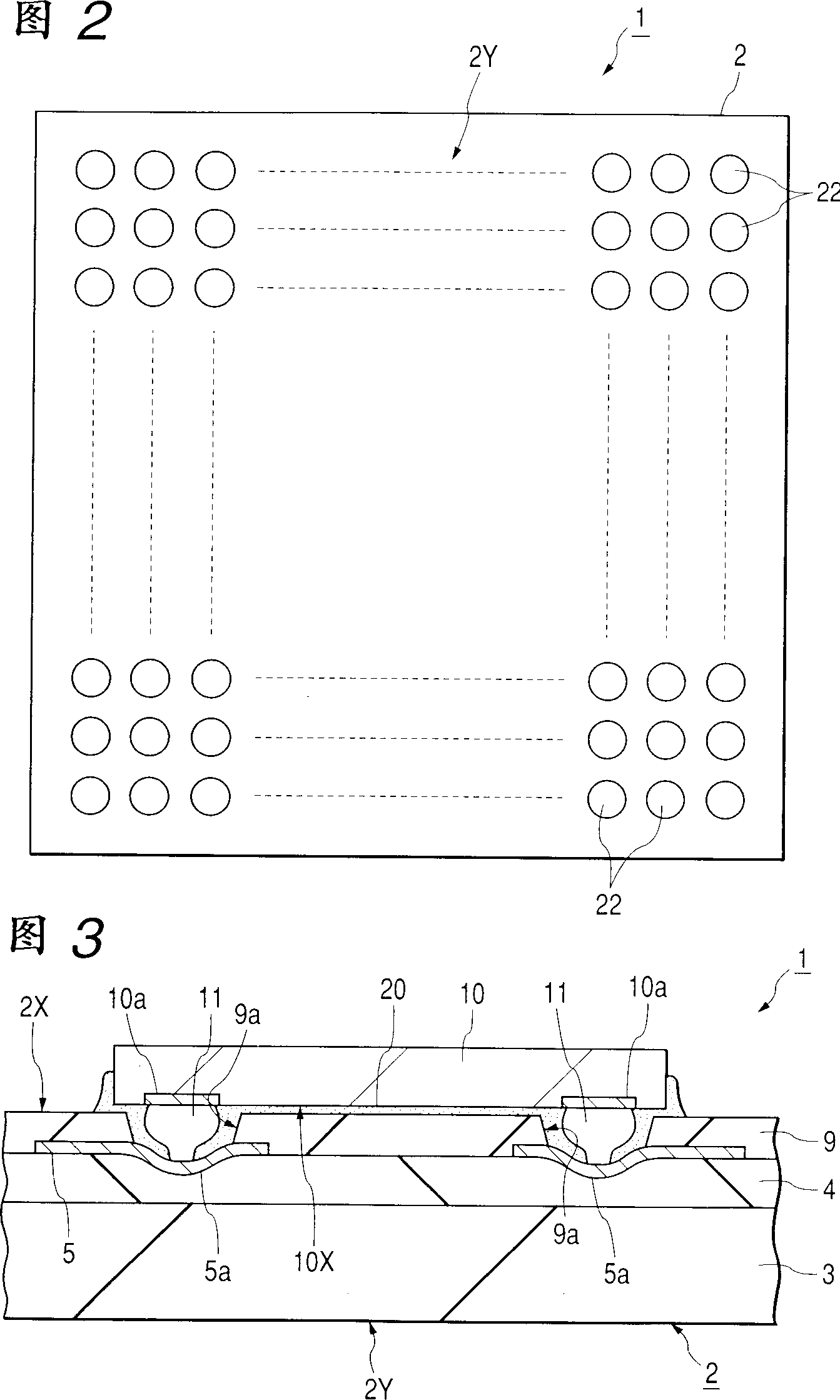

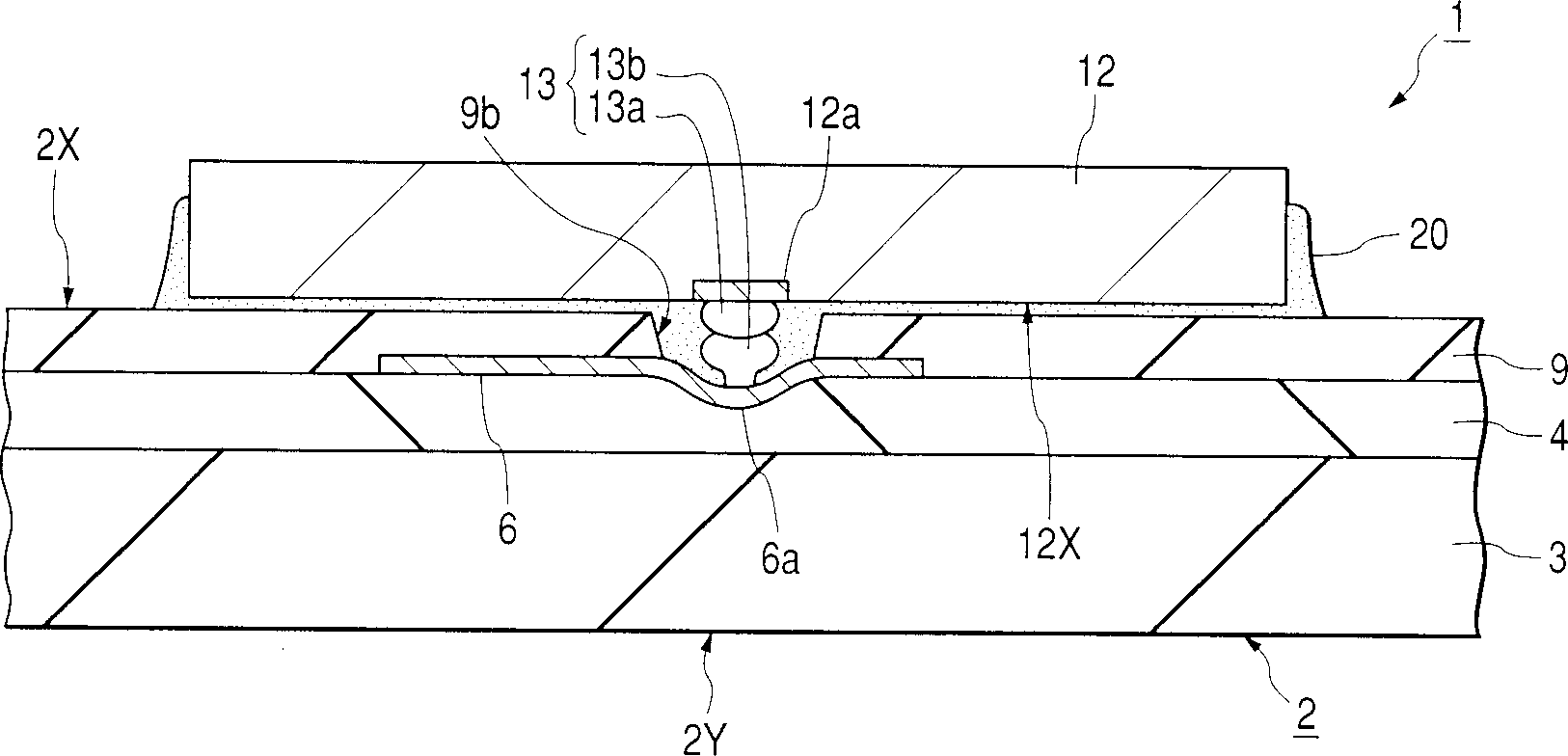

[0063] figure 1 is a schematic plan view of an MCM (an electronic device) according to a first embodiment of the present invention, FIG. 2 is a bottom view of the MCM, and FIG. figure 1 Schematic cross-sectional view of the assembled state of a buffer chip in the MCM, Figure 4 is a representation included in figure 1 A schematic cross-sectional view of the assembled state of a memory chip in the MCM, Figure 5 is a representation included in the figure 1 A schematic cross-sectional view of the assembled state of a controller chip in the MCM, Figure 6 is a representation included in the figure 1 A schematic cross-sectional view of the assembled state of a capacitor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com