Axial gap type motor generator

A rotating electrical machine, axial gap technology, applied in the direction of electrical machines, synchronous motors with stationary armatures and rotating magnets, motor vehicles, etc., can solve the problem of increased noise/vibration, increased wear, and hindered axial gap type rotation. Motor practicality and other issues to achieve the effect of reducing vibration/noise and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, embodiments of an axial gap type rotating electric machine according to the present invention will be described with reference to the drawings.

[0046] (first implementation)

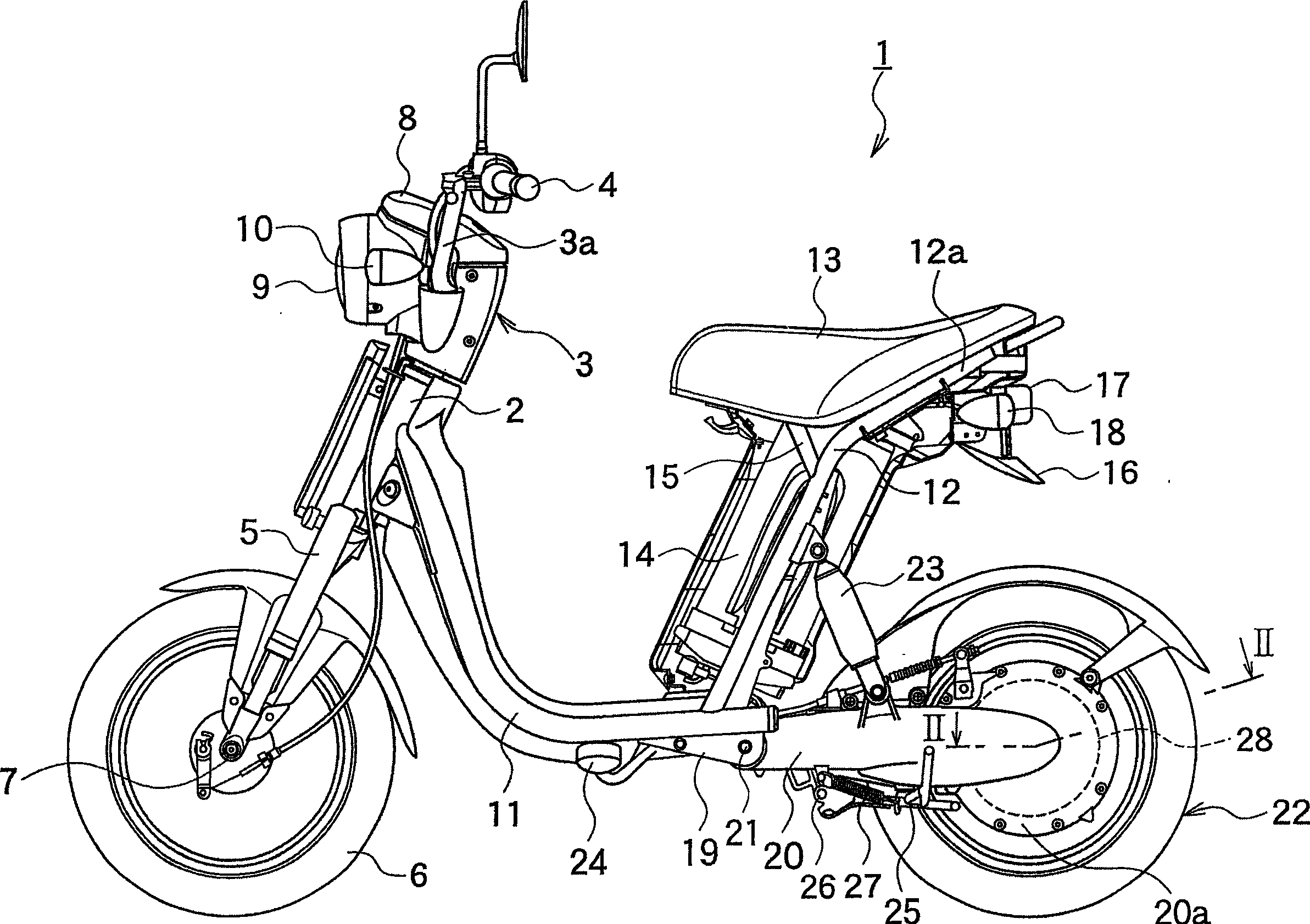

[0047] figure 1 It is a side view of an electric motorcycle 1 as an example of a device equipped with an axial gap type rotating electric machine according to the first embodiment of the present invention.

[0048] Such as figure 1 As shown, the electric motorcycle 1 is equipped with a front pipe 2 at the upper part in front of its vehicle body, and in this front pipe, a steering shaft not shown in the figure for changing the direction of the vehicle body is passed through freely rotatably. On the upper end of the steering shaft, a handle support portion 3 for fixing a handle 3a is attached, and handles 4 are attached to both ends of the handle 3a. In addition, the right side not shown in the figure ( figure 1 The handle 6 on the inner side) constitutes a rotatable throttle control han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com