Method for maintaining indoor busbar knife brake movable contact without power-off of high pressure busbar

A technology for high-voltage busbars and busbar cutters, applied in electrical components, switchgear and other directions, can solve problems such as hidden safety hazards, low work efficiency, and complicated operations, and achieve the effects of safe and reliable work, improved work efficiency, and reduced power outage range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Its technical solution includes the following steps: (1) disconnect the high-voltage circuit breaker that needs to be overhauled, pull open the busbar knife switch, and check that the dynamic and static contacts of the busbar knife switch have been disconnected and there is no foreign matter;

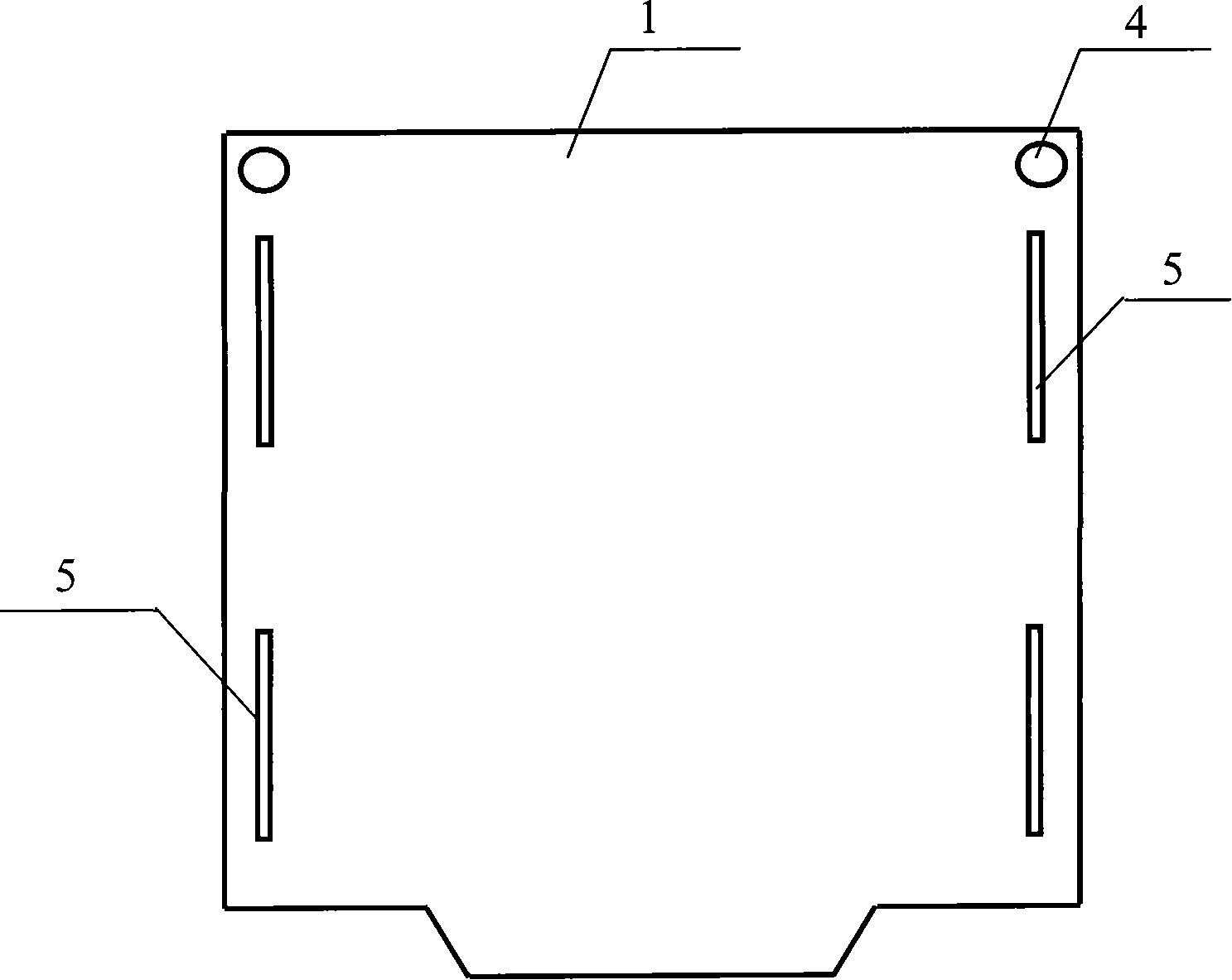

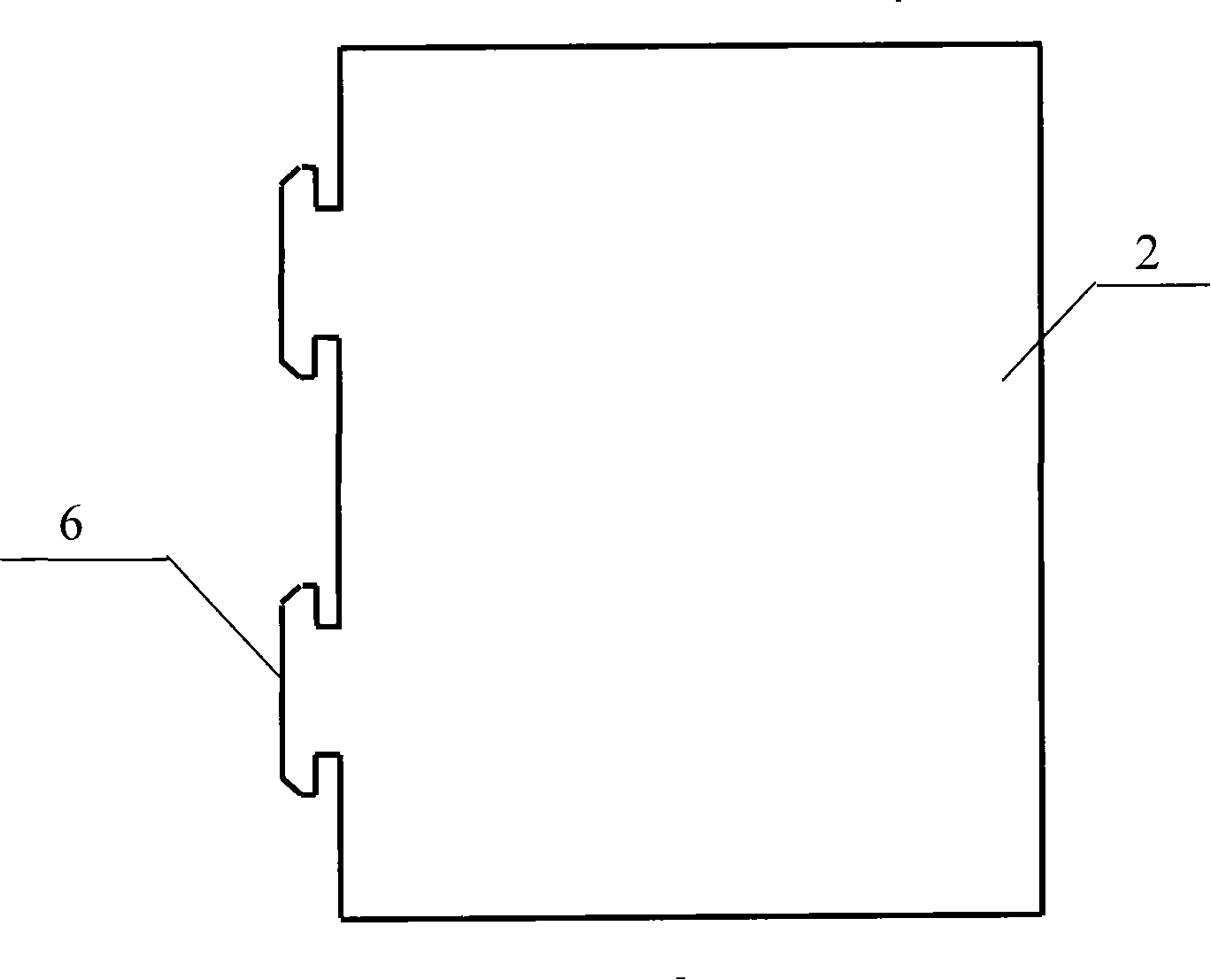

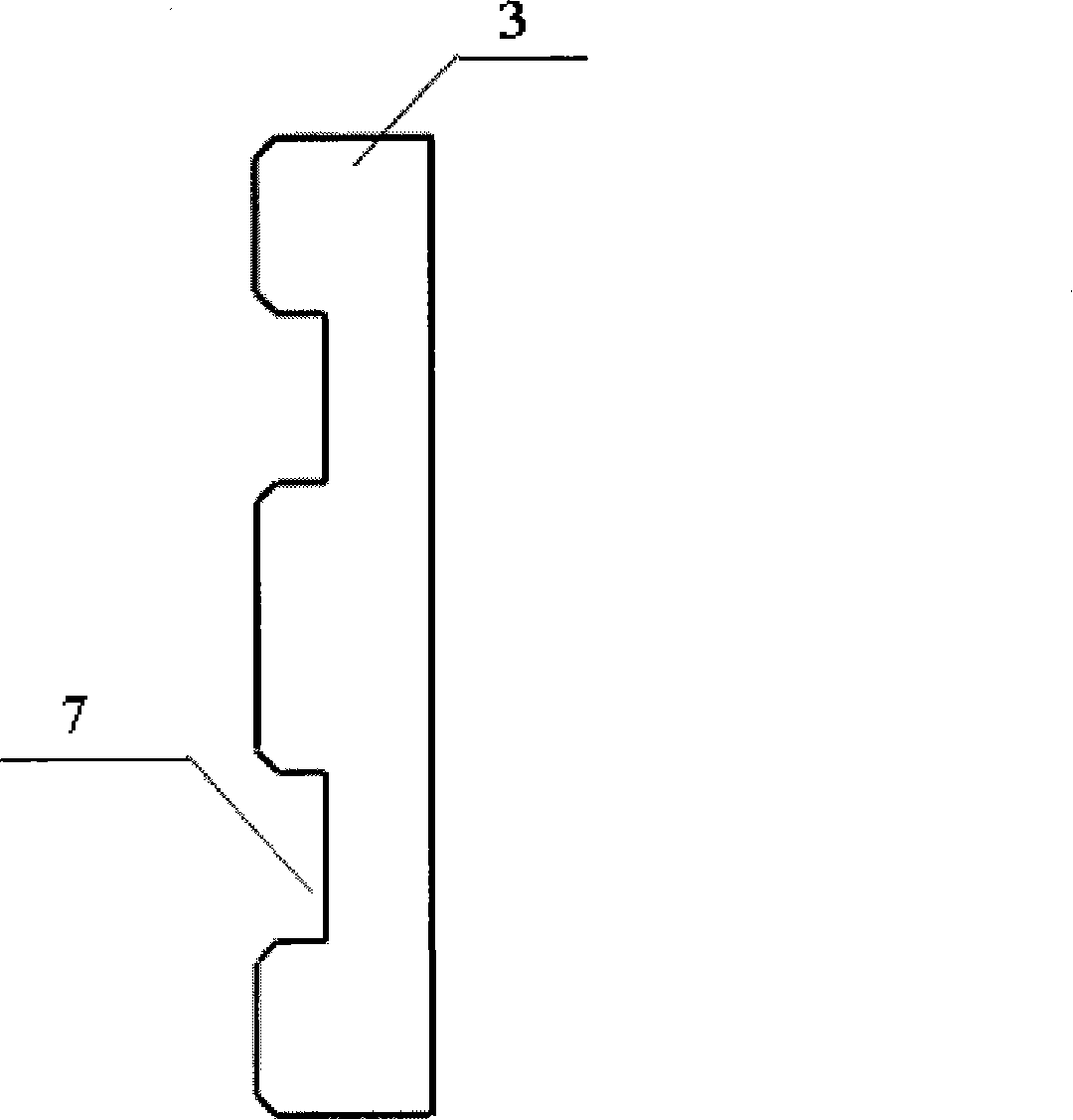

[0027] (2) Assemble the main board and side panels of the insulation isolation baffle for live maintenance according to the live equipment around the dynamic and static contacts of the opened busbar knife switch;

[0028] (3) Fix the main board and the side panels of the insulating isolation baffle firmly with insulating clips to form a live maintenance insulating isolation baffle in the shape of a cuboid with three isolation surfaces;

[0029] (4) Use insulating rods to lift up the assembled live maintenance insulation isolation baffle and place it between the dynamic and static contacts of the opened busbar knife switch;

[0030] (5) Confirm that the insulation and isolation ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com