A milling cutter head and a milling cutter tool with holow spaces for receiving a male element

A technology for milling cutters and cutter heads, applied in the field of milling cutter cutter heads and milling cutter tools with hollow spaces for receiving male elements, which can solve the problems of not being utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

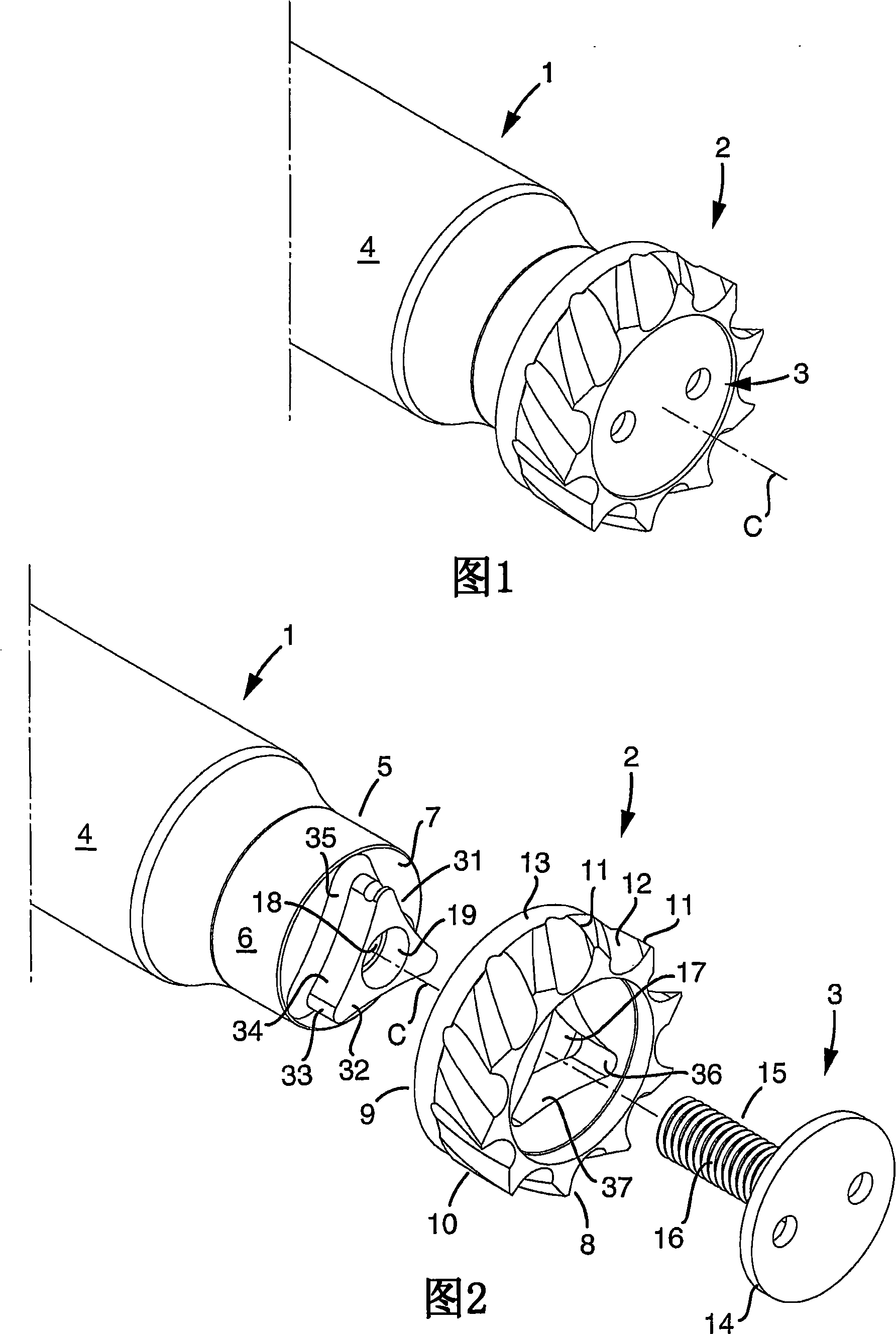

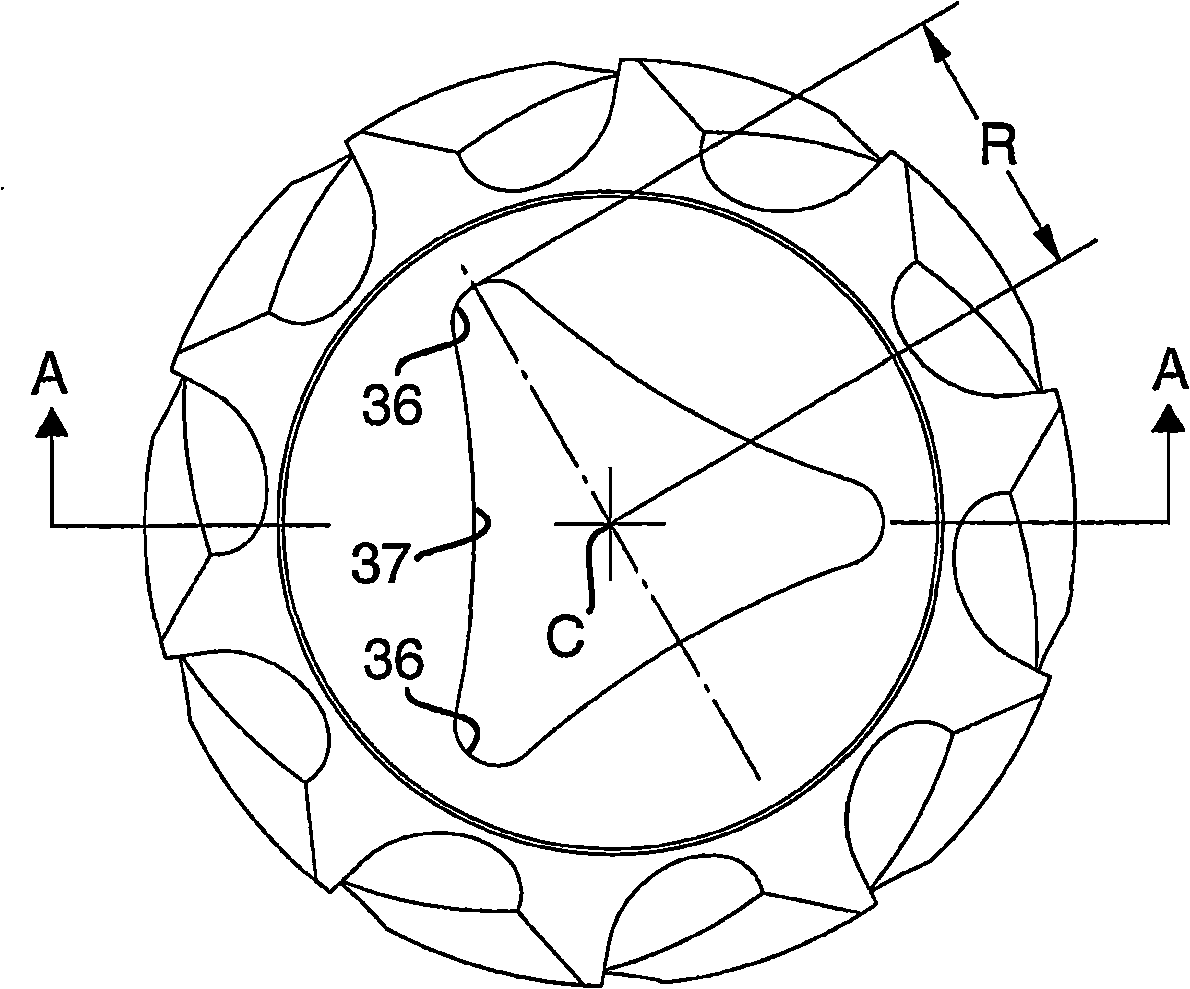

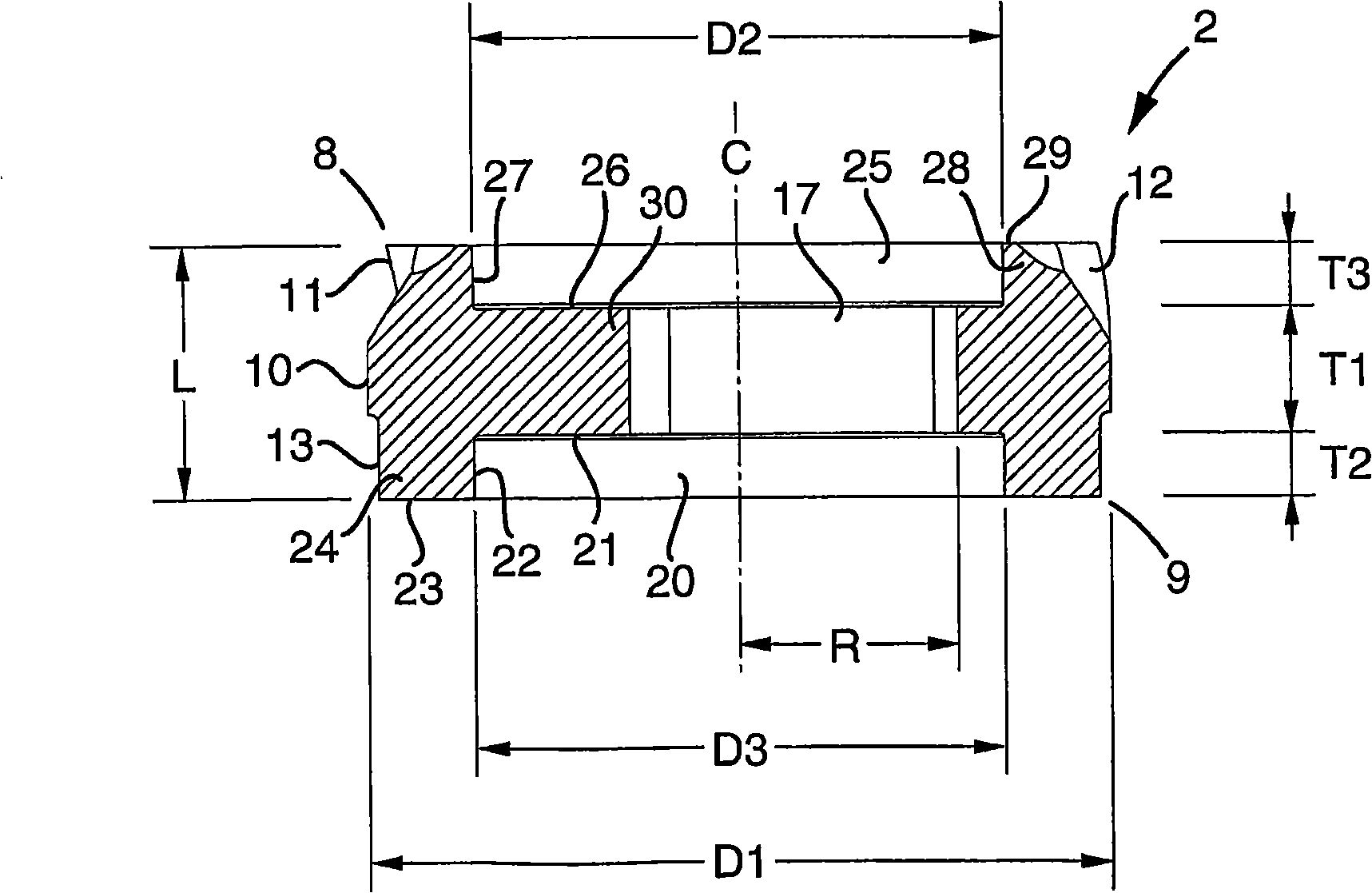

[0020] In FIGS. 1 and 2 , a milling cutter tool made according to the invention is shown, consisting of a rotatable base body 1 and a replaceable milling cutter head 2 . For fastening the milling head on the base body, fastening means 3 are used, which in the exemplary embodiment shown are in the form of front-mounted screws.

[0021] In this example, not only the milling cutter head 2 but also the basic body 1 has a rotationally symmetrical basic shape defined by a central axis C around which the tool can rotate. Advantageously, but not necessarily, the base body 1 has an elongated shape, ie, in this example, defined by a cylindrical envelope surface 4 along a substantial part of its length. At its front free end, the basic body transforms into a thinner, male element or component 5 , which is delimited by a rotationally symmetrical envelope surface 6 and a planar end face 7 . Most suitably, the envelope surface 6 is cylindrical.

[0022] The milling cutter heads 2 each hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com