Intake unit

A suction unit, suction catheter technology, used in non-displacement pumps, jet pumps, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

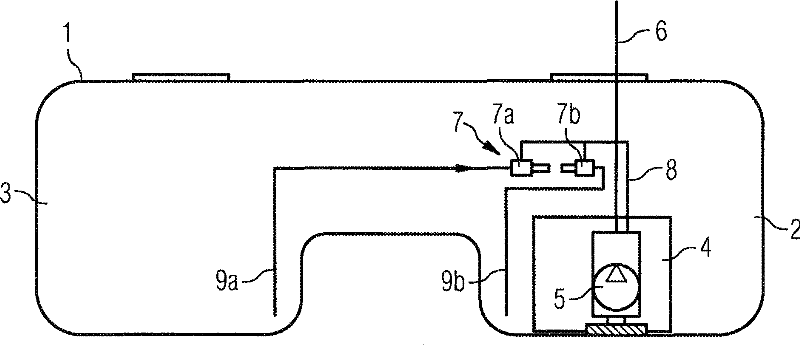

[0018] exist figure 1 The fuel tank 1 shown in has two chambers 2 , 3 separated from one another in the bottom region. A swirl box 4 with a fuel pump 5 located therein is arranged in the chamber 2 . A fuel pump 5 delivers fuel to an internal combustion engine (not shown) via a pre-pipe 6 . A suction unit 7 according to the invention is used for filling the swirl tank 4 , which consists of a first jet suction pump 7 a and a second jet suction pump 7 b. The suction unit is fastened to the swirl box 4 in the region of its upper edge. Via the working medium line 8 provided by the fuel pump 5 , the ejector pumps 7 a , 7 b are operated. Each of the jet pumps 7a, 7b has a suction duct 9a, 9b which leads into the bottom area of each chamber 2, 3, so that the fuel is conveyed from the fuel tank 1 to the swirl tank 4 in.

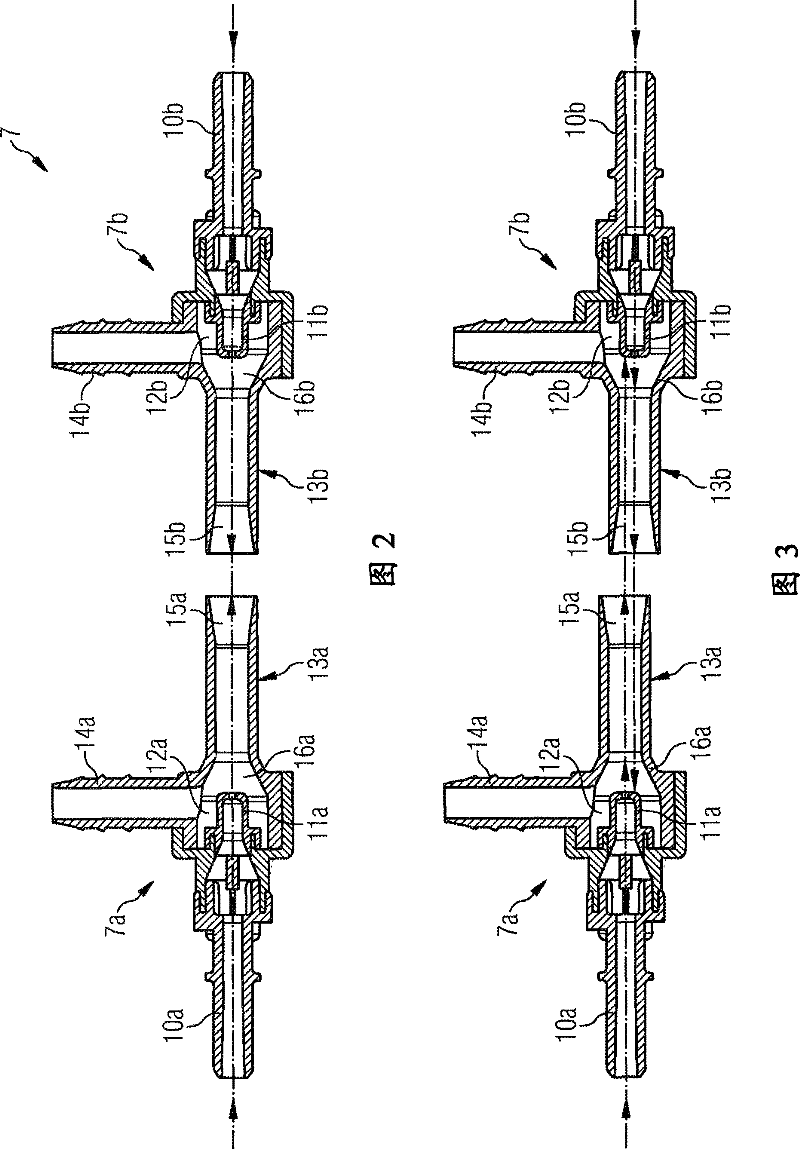

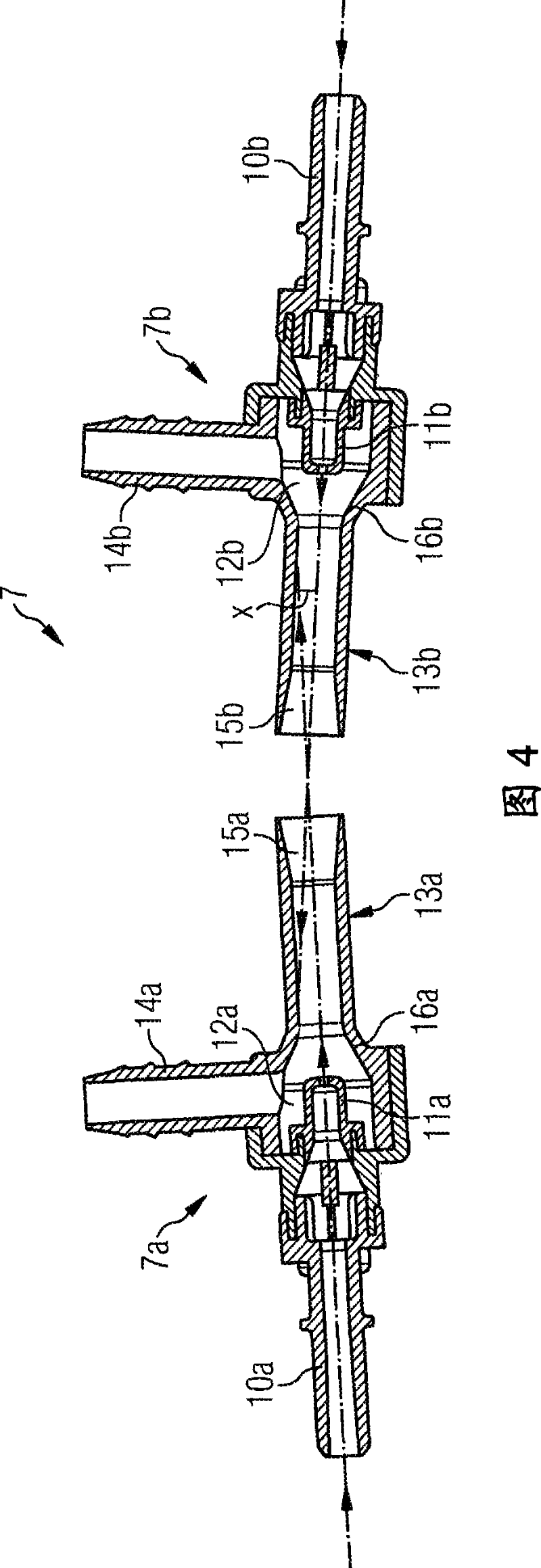

[0019] figure 2 show figure 1 The suction unit 7, but it is not fixed on the anti-swirl box. The two jet pumps 7a, 7b have the same structure. A working m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com