Microcomputer operated polisher

A technology of polishing machine and control command, applied in the field of polishing machine, can solve the problems of high cost, rough surface, the glasses frame cannot effectively control the moving speed of the glasses frame, etc., and achieves the effect of good rigidity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

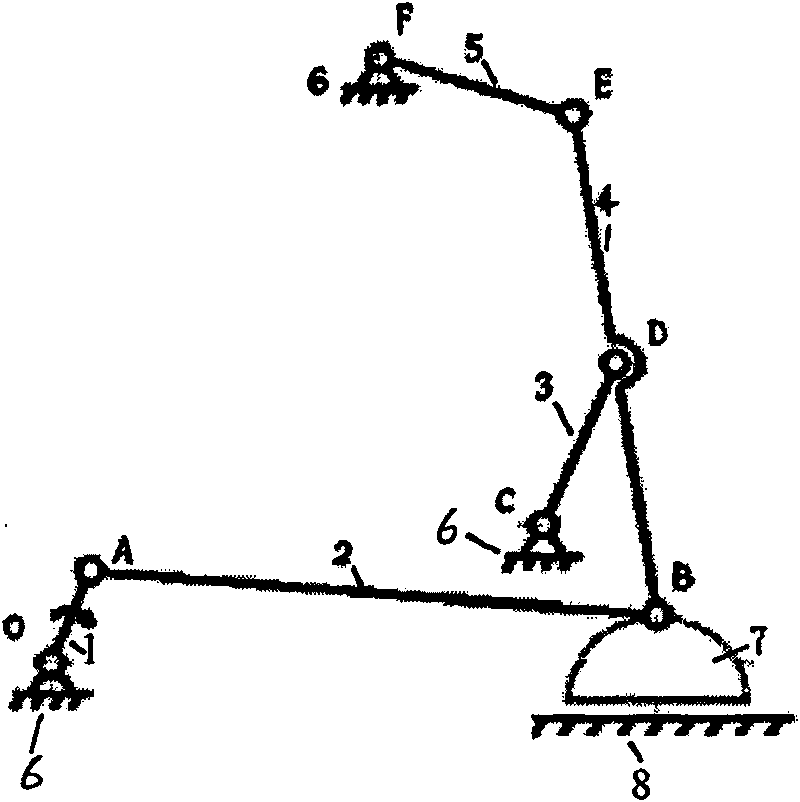

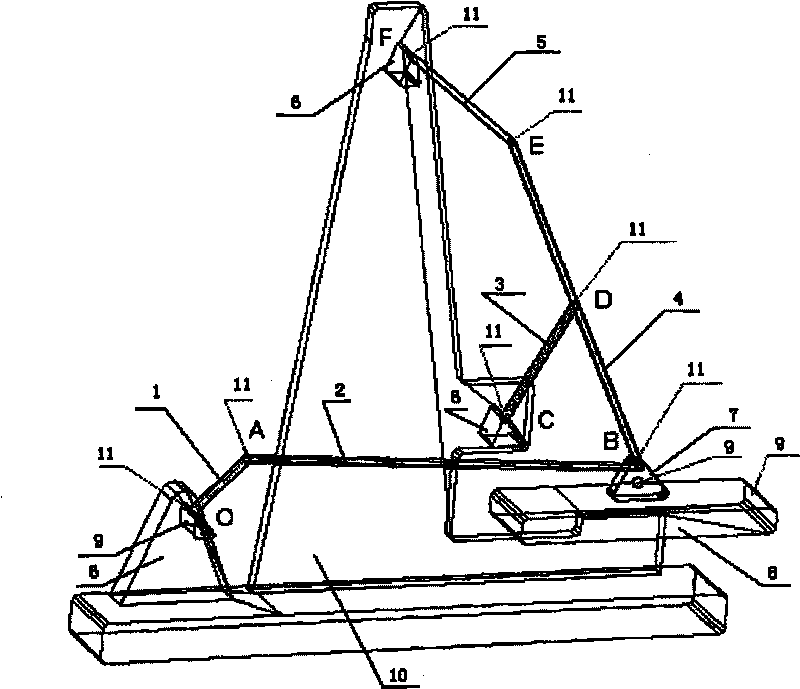

Method used

Image

Examples

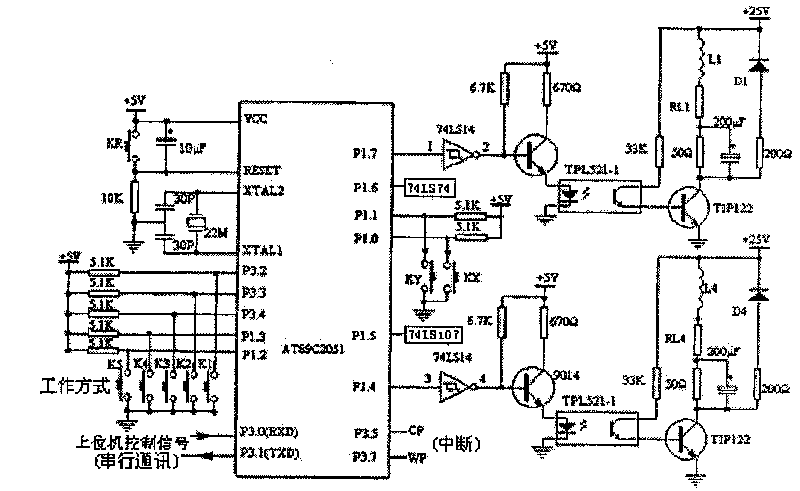

Embodiment 1

[0029] refer to figure 2 , a polishing machine driven by a stepper motor controlled by a microprocessor, which is composed of a microcomputer control system 10 (computer, single-chip microcomputer (AT89C2051)), coaxially installed "stepper motor, encoder and harmonic reducer", driver, The executive mechanism (polishing machine mechanism) and workbench 8 are composed. The executive mechanism of the polishing machine is driven by the stepper motor 9, that is, the mode of pulse + direction signal is adopted, and the mode is serial communication: use VC on the computer ++ Language programming polishing control interface, support Windows2000 / XP operating system. The upper computer (PC) sends the control command to the single-chip microcomputer. When using it, the driver is connected to the encoder. According to the control command, the stepper motor performs forward rotation, reverse rotation, acceleration, deceleration and stop according to different pulse signals. , to automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com