High accuracy barrel finishing machine with full automatic adjustable pressure and dual stepless speed changing

A continuously variable, high-precision technology, used in grinding machine tools, grinding devices, electrical components, etc., to achieve the effect of good rigidity, reliable performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the drawings:

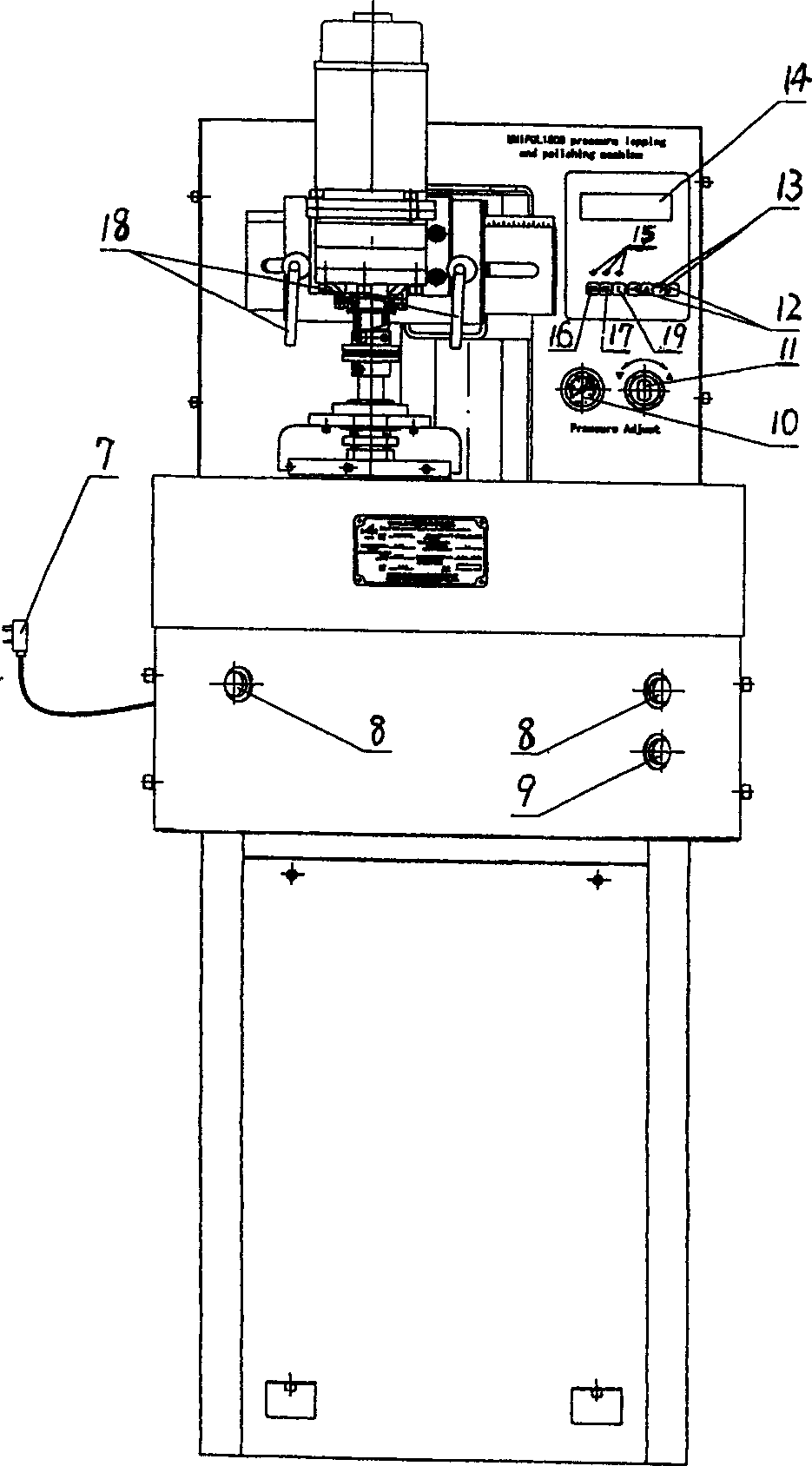

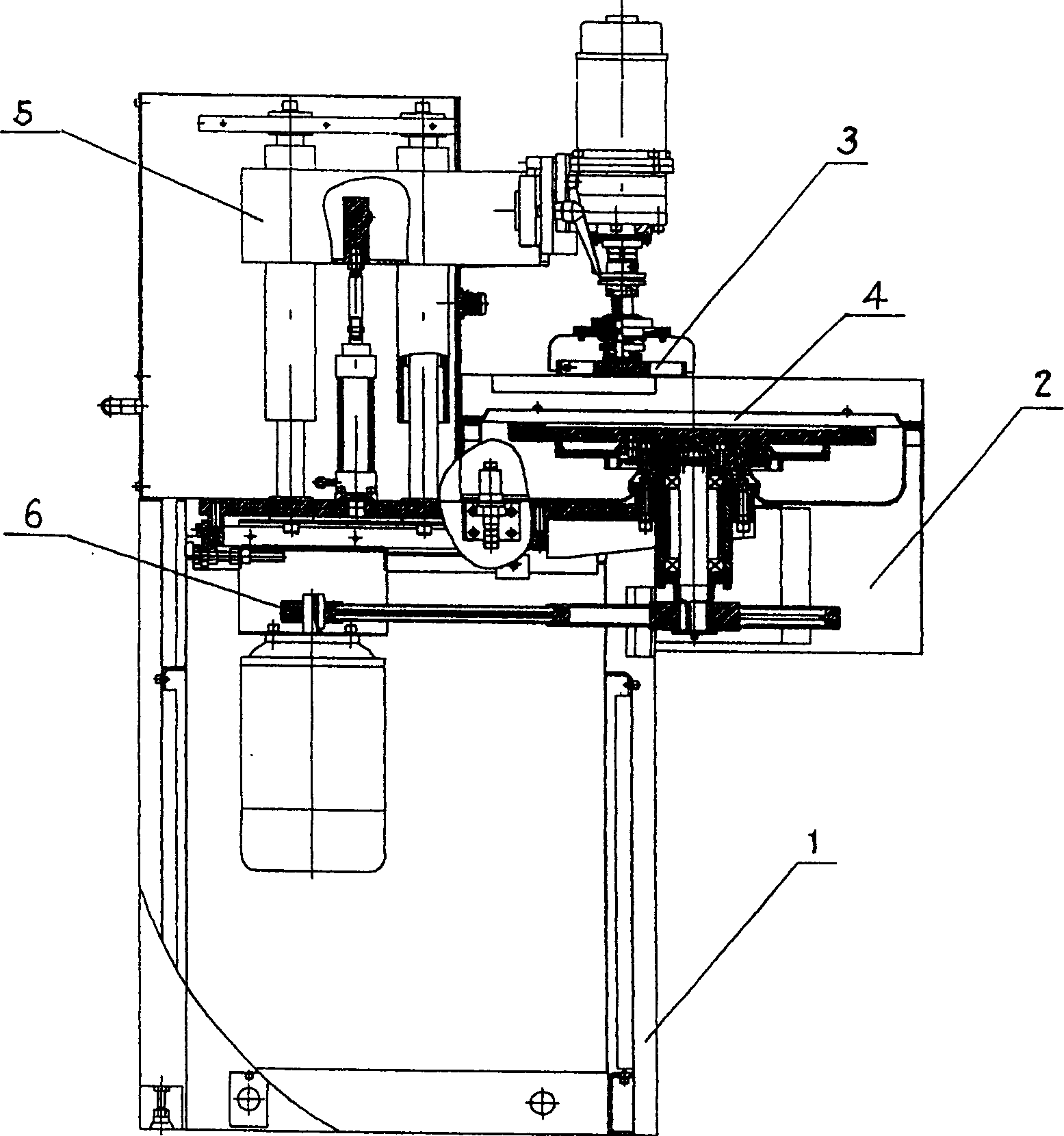

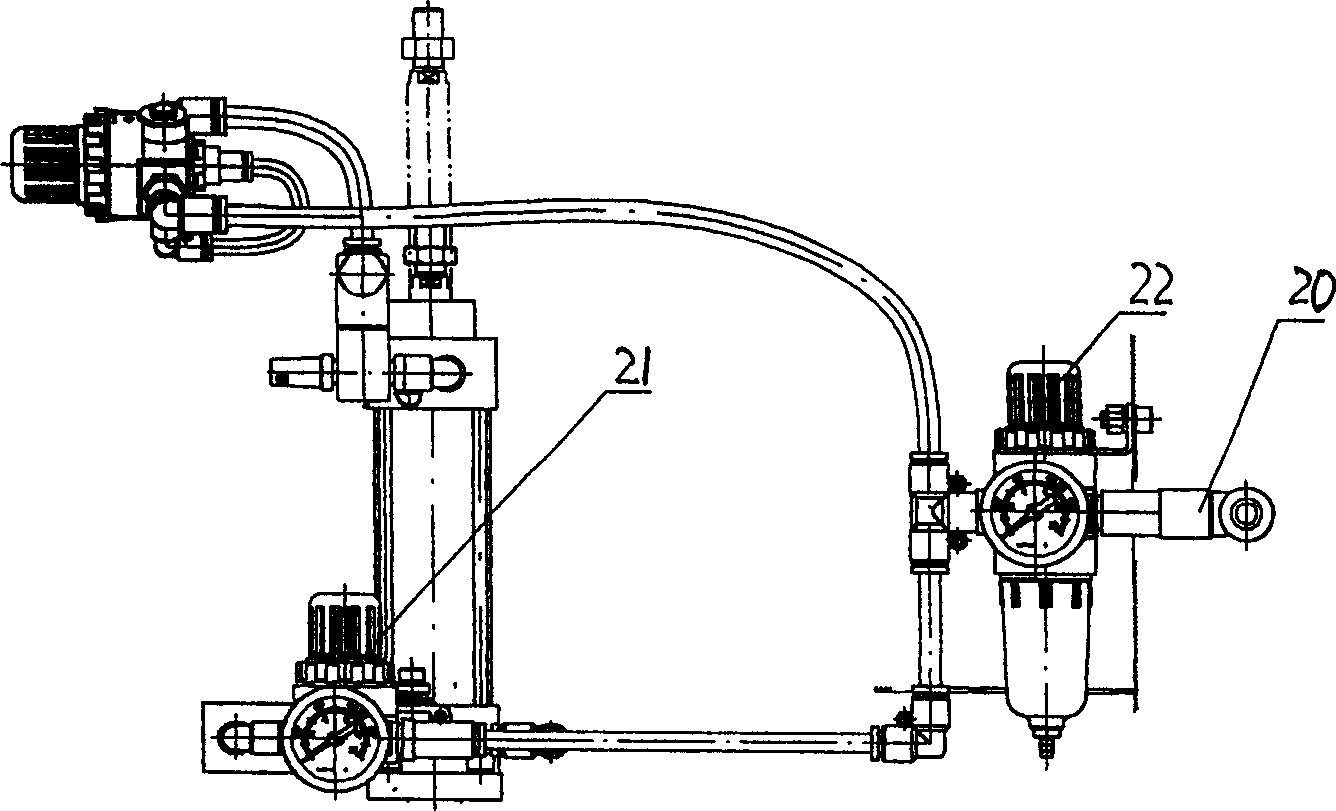

[0020] Such as figure 1 As shown, the equipment can be directly placed on a level ground. After leveling, put the anchor screws at the bottom of the upper frame (1) or float on the ground with a rubber plate at the bottom, adjust the level, and land on the four legs firmly. Insert the plug (7) into a single-phase 220V AC power socket with a ground wire or a switch, turn on the power, turn the sample plate pressure regulating knob (22), and adjust the air pressure to 0.6-0.8Mpa (6-8kgf / cm 2 ) Within the range. Then turn the balance air pressure adjustment knob (21) of the pressurizing arm to adjust the balance air pressure entering the air chamber under the cylinder at 0.23-0.3Mpa (2.3-3kgf / cm 2 ), overcome the balance of gravity and resistance of the pressure arm to push it upward. Then press the two green button switches (8) with both hands at the same time, and the displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com