Internally guided needle

一种导向、针体的技术,应用在针织、纬编针织、经编针织等方向,能够解决增加用于针织工具的床制造复杂性、制造复杂、楔形条制造复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

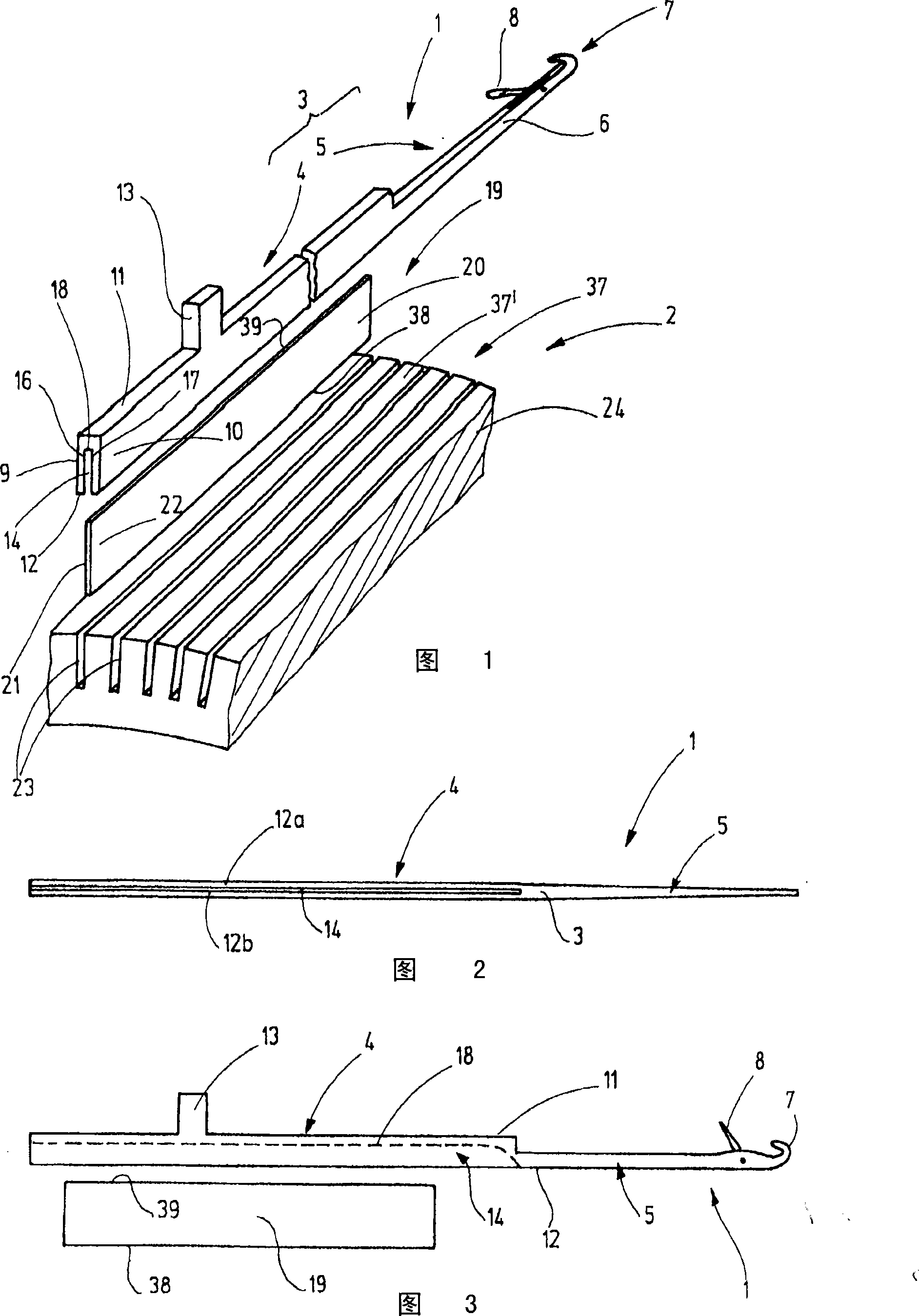

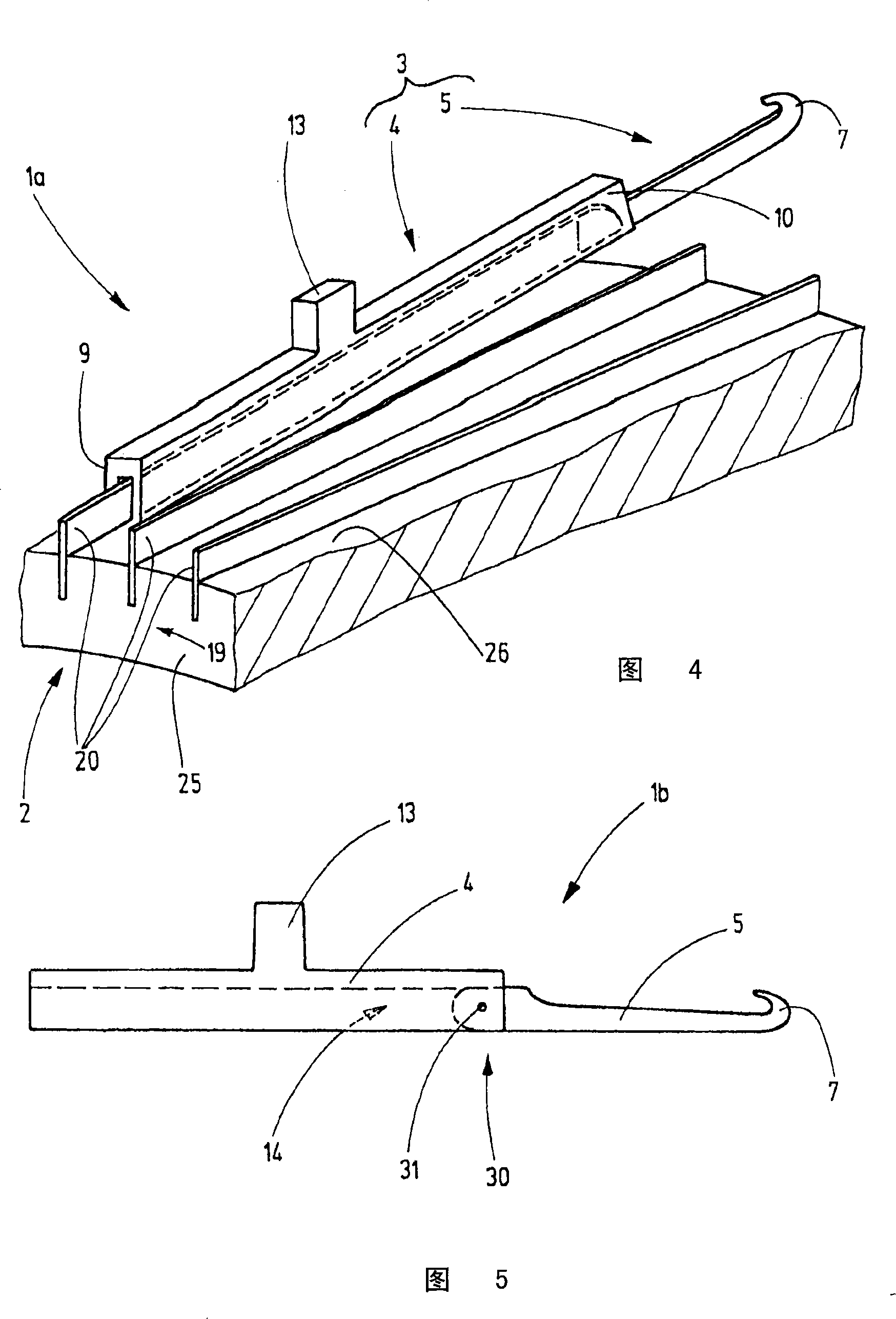

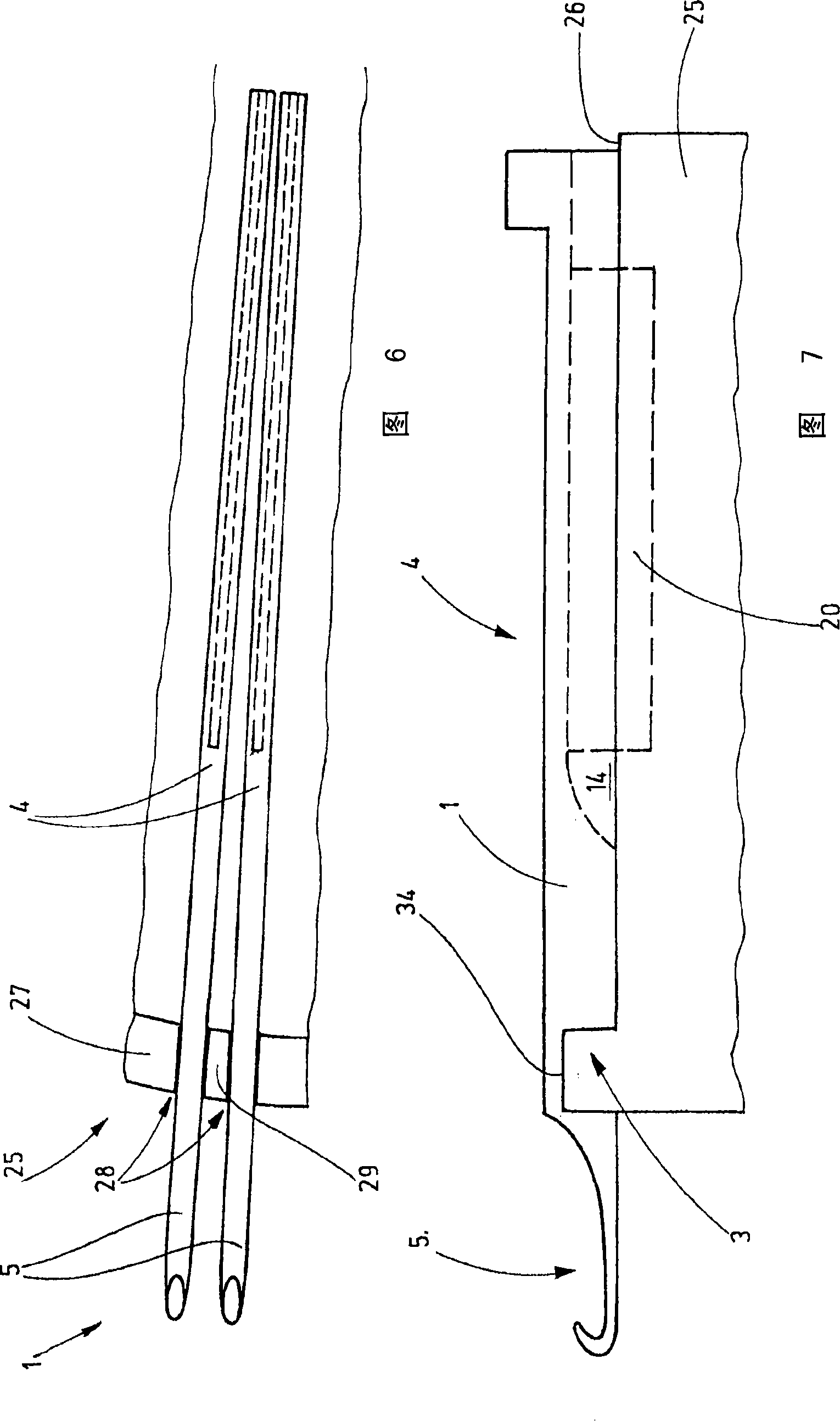

[0027] FIG. 1 shows a needle 1 and an associated needle holder in the form of a needle bed 2 . For purposes of illustration, needle 1 is a tongue needle. However, other knitting implements also exist, such as crochet hooks, transfer needles, compound needles, cutting needles, rods, and the like. The needle has a needle body 3 which is divided into a bearing part 4 and a loop forming part 5 . Referring to this exemplary embodiment, the two form a seamless one-piece unit. The loop forming part 5 extends in a straight extension from the support part 4 , like the shaft 6 . The shaft 6 has at its end a hook 7 and a closing member 8 for the hook 7 , eg in the form of a tongue, slide or the like. In the form of a tongue, the closing member 8 is supported to be pivotable towards and from the hook 7 . The tongue extends into a groove extending through the shaft 6 . However, applications are conceivable in which the knitting tool 1 does not require the closure member 8 .

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com