Gas pump for mixing gas during processing flour food

A technology of food processing and mixed gas, which is applied in the direction of pre-baked dough processing, etc., and can solve the problems of cakes, biscuits, and bread with hard texture and no crispy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

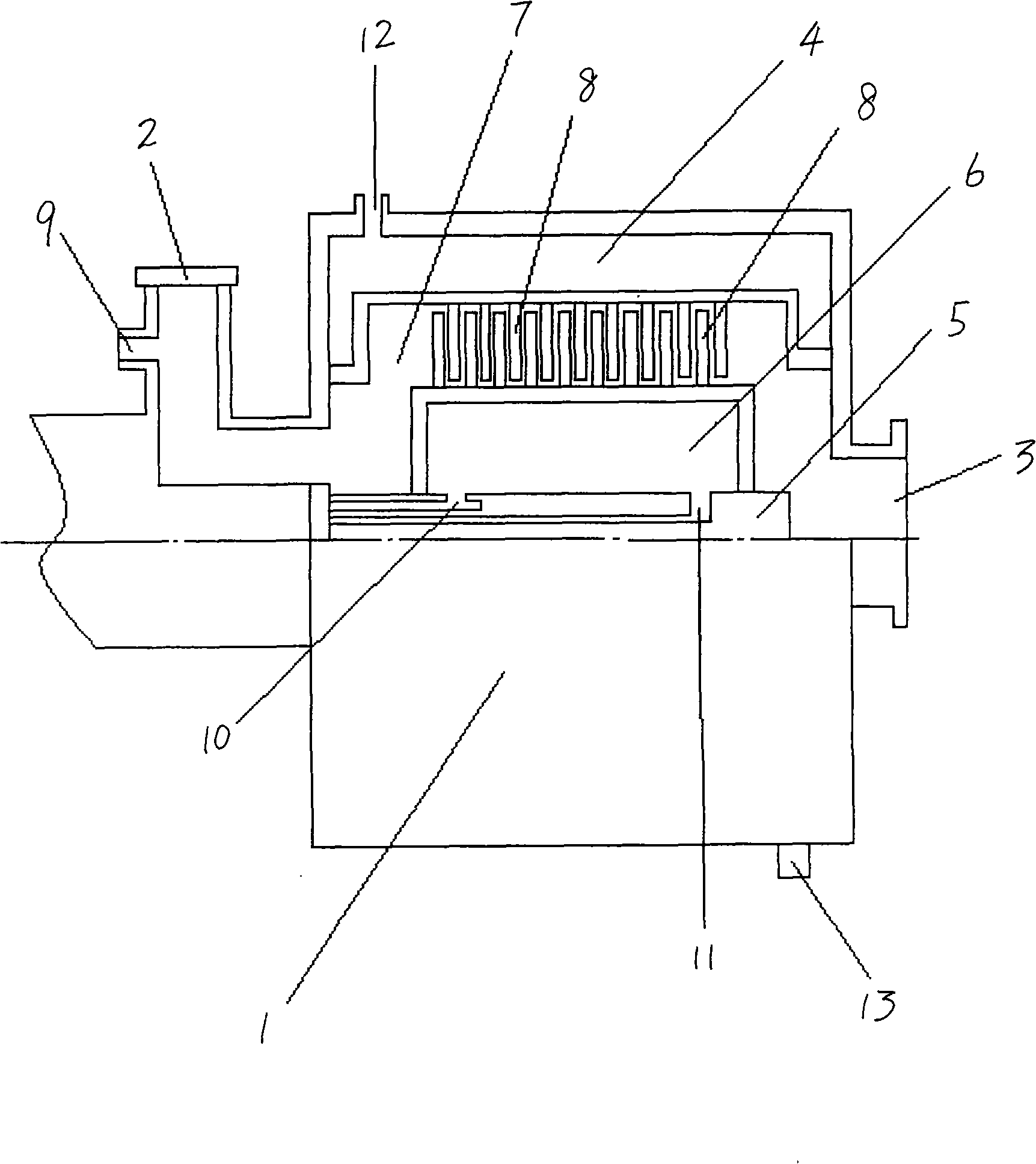

[0006] The figure includes a pump casing 1, a feed port 2, and a discharge port 3. It is characterized in that: the pump casing 1 is a cylinder with an interlayer 4, and there is a coaxial rotor 5 on the central axis of the pump casing 1, and the outer side of the rotor 5 is connected There is a hollow body 6, and there is a gap 7 between the inner layer of the interlayer 4 of the pump casing 1 and the hollow body 6 outside the rotor 5, and the inner layer of the interlayer 4 of the pump casing 1 and the surface of the hollow body 6 outside the rotor 5 are respectively There are several protruding and intersecting strip teeth 8, the front end of the pump housing 1 is connected to the feed port 2, and the feed port 2 has an air inlet 9, and the rear end of the pump housing 1 is connected to the discharge port 3. The rotor 5 has an inlet pipe 10 and an outlet pipe 11 connected to the hollow body 6 outside the rotor 5 , and the pump housing 1 has an inlet pipe and an outlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com