Disc type leavening assembly for full-automatic cake leavening device

A disc type, whipper technology, applied in dough mixers, structural components of mixing/kneading machinery, baking, etc., can solve the problem of high energy consumption of whippers, save electric power, save production costs, and reduce enterprise costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

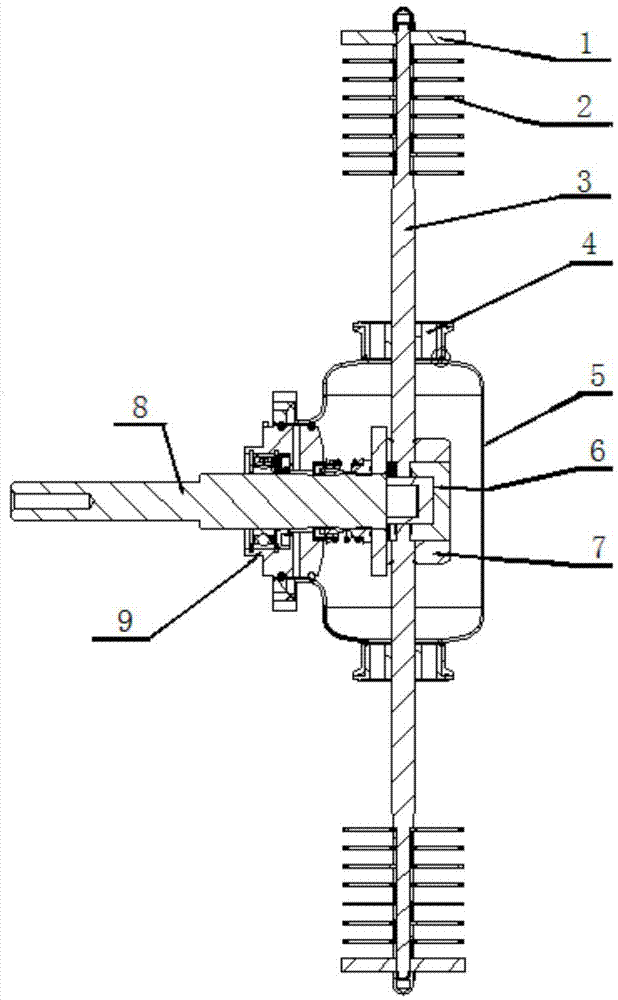

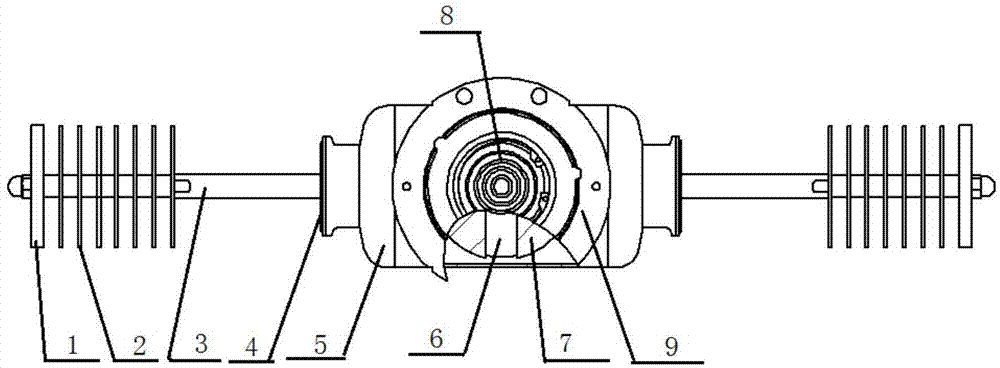

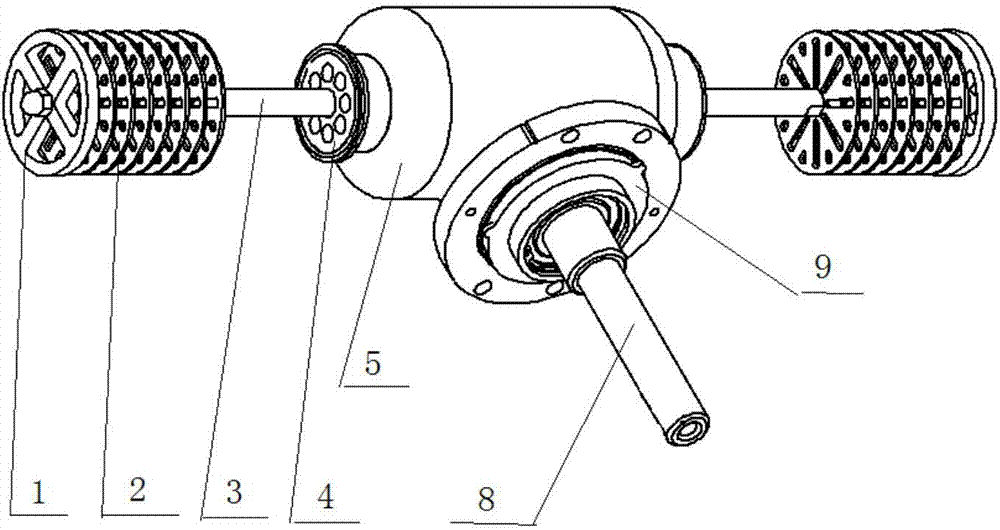

[0027] Embodiment 1: as attached Figure 1 to Figure 4 As shown, a transmission mechanism is installed inside the power housing 5, and one end of the power housing 5 is connected to the transmission shaft 8. At the same time, a connecting rod 3 is installed on the other side of the power housing 5 in a direction perpendicular to the transmission shaft 8 through a lotus root piece 4. On the connecting rod 3 The metal spring sending disc 2 is connected in series, and the metal spring sending disc 2 is in the shape of a disc, and the metal spring sending disc 2 is axially opened.

[0028] In the foregoing, a metal spring is connected in series on the connecting rod 3 to send out the disc 2. A plastic sound-absorbing sheet 1 is installed on the outer side of the plastic sound-absorbing sheet.

[0029] In the foregoing, the transmission shaft 8 is installed on the power casing 5 through the sealing and fixing seat 9 .

[0030] In the foregoing, in the power casing 5, the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com